Introduction

Do you ever wonder what the main reason for the upgrade in the quality of machined parts is? Technological advancement has bought many techniques, for example, custom CNC machining. It has entirely changed the manufacturing industry.

We believe that we must bring about an extensive change by creating revolutionary products. We do this by bringing you the most qualified engineers from around the world.

No matter the geometric shape, we take pride in paying attention to detail. This is how we come up with precise, custom machined parts.

To proceed further, you must know how CNC machining works.

What Is CNC Machining, And How Does It Work

It is a method that uses many tools to perform manufacturing tasks and creates a final design. Customers ask for specific geometric shapes, and that’s when custom CNC machining comes in. From defense to aerospace, this technology has changed the way we used to look at the world.

CNC machining uses precision and accuracy to its advantage.

It performs the same functions such as metal cutting, grinding, and milling as traditional machining. One major difference is that it uses a computer rather than a machinist.

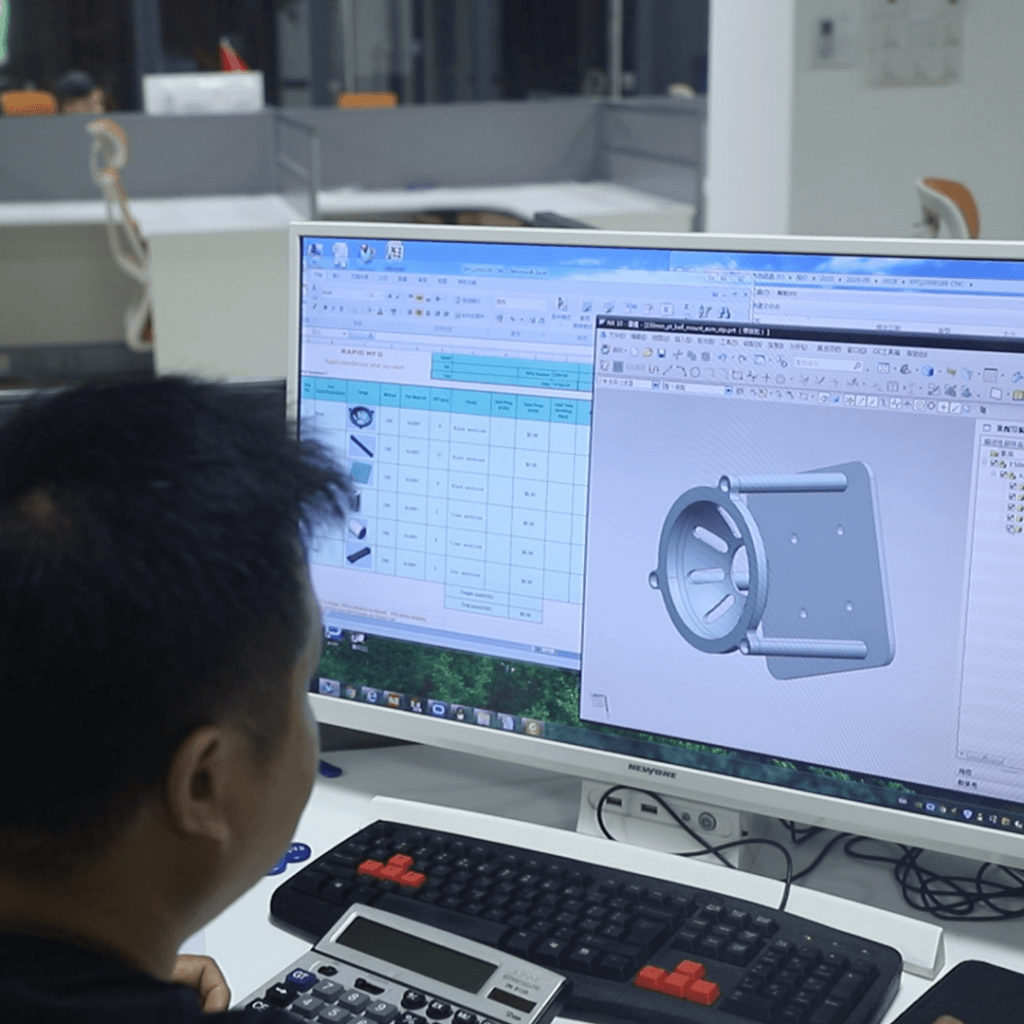

CAM software, along with the CAD model, is used to give instructions. It uses raw material and changes it to its final form by removing materials. It goes through an elaborate process of drilling holes, bored pathways before taking its final shape.

The CAD model provided by the customers is programmed into the CAM software. Then it starts generating G-codes and instructs the machine on how to work.

Custom CNC Machining Services at RJC

We bring online CNC machining services to you, so you don’t have to worry about traveling miles to look for your desired parts.

You can now order at a low cost from the comfort of your house. With more than 100 types of raw materials, there is no word such as an ‘excuse’ in our dictionary.

Our specially designed milling machines can cut through any solid material. Our tools are specialized to make the parts into their desired shapes and sizes.

These tools may include cutters, fluted mills, face mills, and ball end mills.

If you’re still not sure, then we must tell you what it is. 3-axis and 4-axis are used to make shapes of simple geometries.

They are more affordable, but 5-axis is used to produce shapes that are not common. No doubt, compared with the rest, 5-axis is more efficient.

It is important to apply surface finishes to change the appearance, hardness, rough surface and chemical resistance of the parts produced.

It is after this that we start inspecting the end product before shipping it to our valued customers.

This process holds the raw material and rotates it. At the same time, the specialized tool used is to remove the material and create the desired geometric shape.

Another name for this type is “subtraction machining” since it subtracts material. Our machines produce custom prototypes quickly because we use CNC lathe with additional features to make it happen in a short time.

If you have a simple cylindrical shape in mind, CNC turning machines can get you your desired shape at a low cost.

If the design is different, then it is assessed differently. With our top priority to not let the customer walk out without their desires fulfilled, we believe we must look into every case differently.

If the machine has milling and turning capacity at its center, then it can easily mill it out of other shapes. You will not have to worry about your CNC machining parts.

Turning Materials

When you have the design in mind, you must look for the only material that will be good for your end product.

The properties of the material affect the durability, functionality of your product. It also has an impact on how it responds to the manufacturing process.

The material will determine which type of machine will work best and what shape will be achieved by the end of the process.

We have plenty of materials, including custom CNC milling wood, plastic, and metals. Aluminum is the easiest to the machine.

It is usually used by clients when they have a complex design in mind. Materials with a lot of carbon tend to have a certain level of hardness and strength that doesn’t allow them to be machined properly.

But when it is machined, it resists any damages and stays stable for a very long time. Even if you expose it to high temperatures, it stays the same.

Brass, on the other hand, is noncorrosive and doesn’t require much strength. It can be used for a long time.

Copper is quite expensive and conducts electricity, so special care is required when machining such material. It also doesn’t produce the desired end product.

Steel is an alloy, so it has the properties of the other materials in it. These materials also increase their machinability.

Thermoplastic and thermosets are the two types of plastics used by many clients. It is because the process that they are willing to select supports this type of material.

Thermoplastics do not lose their basic properties even if you heat, cool, or reheat them. It can be reformed without any permanent change.

Thermoplastic is an ideal material that we look for because one can always correct their mistake if the client does not like the end product.

Thermosets, on the other hand, go under a chemical change as soon as you heat them. They cannot be reformed or re-melted, so you have to be very careful when choosing your design.

Is My Part A Good Fit For CNC Turning

There are a lot of consideration that goes into account when you need to determine if your part is a good fit for CNC turning or not.

If you’re looking for small-batch CNC machining, we would advise you to go for CNC turning. If it goes over 2.5 OD then prices rise, and you will have to pay for every increase in the OD.

Turning Vs Milling

All you want is your desired design by the end of the process, and we know that it is confusing whether to choose turning or milling. Both are just machining, after all!

The lathes hold on to the bar, and the spindle spins it quickly. It is set at some rounds per minute, thus known as the quick turn CNC machining.

Of course, the speed varies by the material and machine used too. A specialized tool, along with other tools, is attached to the surface.

It eliminates the unwanted material and gives it shape.

Some turning machines have additional features such as drill slots and holes and bring some complex shapes to life. These CNC machining parts are usually smaller and efficient than milled parts.

Milling, on the other hand, rotates the cutting tool rather than the workpiece. It is done at preset rounds per minute pace.

If you require a sculptured or a flat surface, then you’re looking for the right service. The milling cutter is also a multi-point cutting tool that works on square or rectangular blocks.

To sum it up, deciding whether to use milling or turning depends on your needs. You must consider the material first and the desired shape

that is required.

Quality Assurance

We use the latest technology to bring the right products to your doorstep. We believe that it is important for you to decide on your own rather than taking advice from multiple other people who know nothing about this particular field.

Inspection after the custom CNC machining is equally important after manufacturing a part. We must compare the original design against the end product to know how far we’ve come.

With our well-maintained machinery and trained staff, we deliver the best results at a low cost along with the required technical support and customer services.

Our continuous improvements in technology help us take pride in fulfilling the quality requirements of our clients.

Contact RJC today to see how we shape your dreams!