Introduction

Technology is a crucial part of our world. It has changed the way we do things. It also reflects in every aspect of our daily activities.

Today, there are many tools that we use to make our tasks more manageable. The tools apply to the medical sector, where doctors use tools for treating patients. The availability of such devices increases how many lives doctors can save.

There are millions of hospitals across the world. Some of these hospitals are in developing countries. Developing countries have poor rural areas without hospitals.

Where there are hospitals, they can’t afford medical equipment. Hence, it is essential for medical tools to be available in large quantities and affordable. With Precision Medical Machining and Prototype Development, it is easier to get these tools to hospitals worldwide.

What Is Precision Medical Machining And Prototype Development

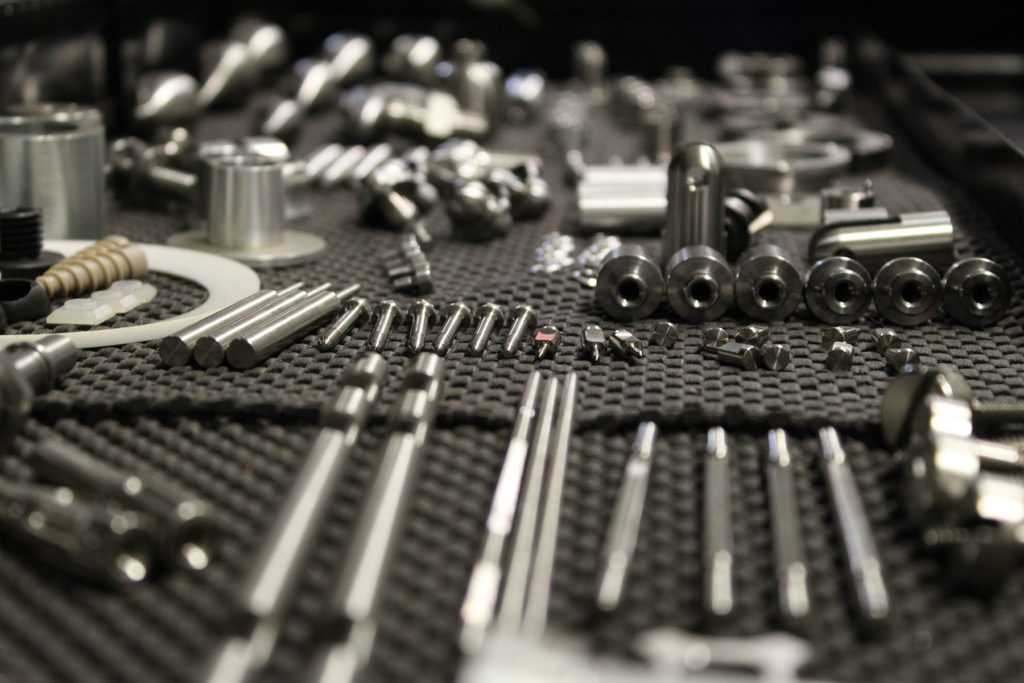

Precision Medical Machining entails the use of accuracy and perfect precision to create medical tools. Precision Medical Machining with Computer Numerical Control (CNC) machines can produce intricate details required for making medical devices.

Precision medical machining requires the development of a prototype. Prototype development involves the entire design and making of a machine. The identification of the different parts is possible after developing the device prototype.

After testing and proving that the models are perfect, the parts can now be mass-produced. The fitting together of the various parts of the device will result in products for public use. Now let’s see why precision medical machining and prototype development are essential.

Importance Of Medical Machining And Prototype Development

- Availability of medical equipment

Prototype development and precision medical machining contribute to the availability of medical equipment. The prototype development with precision medical machining makes it easy to mass duplicate medical equipment.

With the completion of the prototype, it becomes easier to start mass-producing. Machines can quickly make many copies of the equipment.

Machines aid in the production process of medical equipment. The production of medical equipment would have required many people. However, machines can do more at a low price.

The result is medical equipment to go around all the hospitals worldwide. Hospitals can get the different equipment they need through precision medical machining. For most types of medical equipment, a hospital will need more than one.

The average hospital will require more than ten stethoscopes. This vast demand applies to other essential tools. The use of precision medical machining makes it possible to achieve such needs.

- Affordability of medical equipment

Another importance of precision medical machining is affordability. The use of machines in creating tools makes finished products to be affordable. Apart from the initial cost of industrial machines, it is cheaper to use them.

This cheaper cost is as opposed to employing humans whose wages will be higher. The salaries compared to the quantity of work will push up the final product price. In addition, their speed will be slower.

Hence, precision medical machining goes a long way to making the production of medical equipment affordable. As a result, more hospitals will be able to afford it.

Hence, more people worldwide will enjoy quality healthcare services. More hospitals will have the right tools to use. Many hospitals in developing countries and rural areas still find it difficult to afford medical equipment. Hence, several people in these areas cannot get primary healthcare. Most will lose their lives before getting to a hospital with good facilities. Time is very vital in healthcare. If hospitals still lack medical equipment, it will be worst without precision medical machining.

Medical equipment is relatively costly. The cost is due to efforts and materials for making the equipment. Without precision medical machining and prototype development, the price would only become higher. By implication, even more, hospitals will not be able to afford it.

- Eliminate mistakes

The use of precision medical machining helps to eliminate mistakes in the production of medical equipment. Medical equipment is so essential, and accuracy is required to get the best results. A slight medical mistake could worsen the condition or lead to the death of a patient.

Every machine for treating patients must be in the best condition. Several patients could probably suffer if there is an issue with the device due to a mistake during production.

Fortunately, machines make fewer errors than humans. Once devices are programmed to do a thing, they will always do it perfectly. The only instance a machine makes errors is except the engine develops a fault. Such faults are easily noticeable, or in most cases, the machine stops production.

The use of precision medical machining has ensured that most medical equipment in the market is in perfect condition. The implication is lesser mistakes in hospitals by medical practitioners. The medical equipment contributes to reducing human error.

Hence, hospitals can record fewer mistakes and carry out their duties more successfully. These fewer mistakes result from access to an affordable machine and a machine in perfect condition.

- Affordable access to medical services

As discussed, the availability of precision medical machining makes medical equipment more affordable. When medical equipment is more affordable, it also reflects patients’ prices for medical services.

When patients request a service that requires a machine that costs 100 USD, they will pay a small amount. The amount will increase if the device costs 1,000 USD.

The fact that precision medical machining brings down the price of medical equipment also implies that the cost of medical services is lesser. More people will be able to afford medical services. Hence, when they have medical challenges, they will be encouraged to go to the hospital. The patients will know that they can afford the service.

Going to the hospital would not be the case if the prices of most medical equipment were very high. The cost of their treatments will also be very high. They will know they can’t afford such an amount as the hospital will charge them and stay home.

Hence, precision medical machining goes a long way to reducing the cost of medical services, thereby making medical services more accessible. Even in poorer countries, people can make their way to the hospital when sick. They will not be scared of the charges that the hospital will charge.

- Saving of lives

The need to save lives is the whole essence of medicine. Hence, if hospitals cannot save lives, they will be of no use. People should be able to find their way to the hospital when ill. However, they will only do this when they know they will get proper healthcare.

It is also vital that they can afford the cost of the services. If any of these two factors are missing, they will prefer to stay home. Staying home will mean their health condition will deteriorate. They might lose their life as a result.

With prototype development for medical equipment, it becomes easier for medical practitioners to save lives. Most hospitals can purchase the essential medical equipment that they need.

The poorer countries often have a few standard hospitals that can afford expensive machines as well. Hence, when people fall ill, they can go to the hospital to get treated.

Patients are referred to more prominent hospitals when the current hospital cannot treat them. Even though this is risky, they will still have a chance depending on the patient’s state. Such referrals are because of a lack of medical equipment in most cases.

The implication is that many people who would have lost their lives due to a lack of medical equipment, either unavailable or unaffordable, still live because of precision medical machining. As technology continues to improve, medical equipment could get cheaper. There will be lesser referrals, and more people will avoid deaths due to lack of medical equipment.

Final Thoughts

The article covers the value of precision medical machining and prototype development. The presence of this technology has, over the years, saved millions of lives across the globe.

First, the technology makes it possible for medical equipment to be mass-produced. Mass production leads to availability. Furthermore, the equipment is also less costly because it is cheaper to use and maintain. The use of machines also reduces the mistakes that could come from human error.

By implication, many people who could have died are alive. They can access cheaper medical services. Precision medical machining contributes to saving lives. Many hospitals that are well equipped today will struggle without the technology. The hospitals will not be able to afford most of the equipment. Hence, they won’t have the necessary equipment to attend to their patients.

RJC is one of the companies that have perfected the art of developing prototypes. They develop models for various types of tools, including medical equipment. Over the years, they have developed models for several instruments. The final devices benefit experts and individuals worldwide who need such tools.