Overview of EDM

Electrical discharge machining, or EDM, is an unconventional method in which heat energy is used to remove material from the workpiece. Very similar to processes such as laser cutting, EDM does not require mechanical force in the removal process. EDM is very popular in tool and die manufacturing for its applicability, especially to hard materials such as titanium or particularly complex shapes that are difficult to obtain through milling.

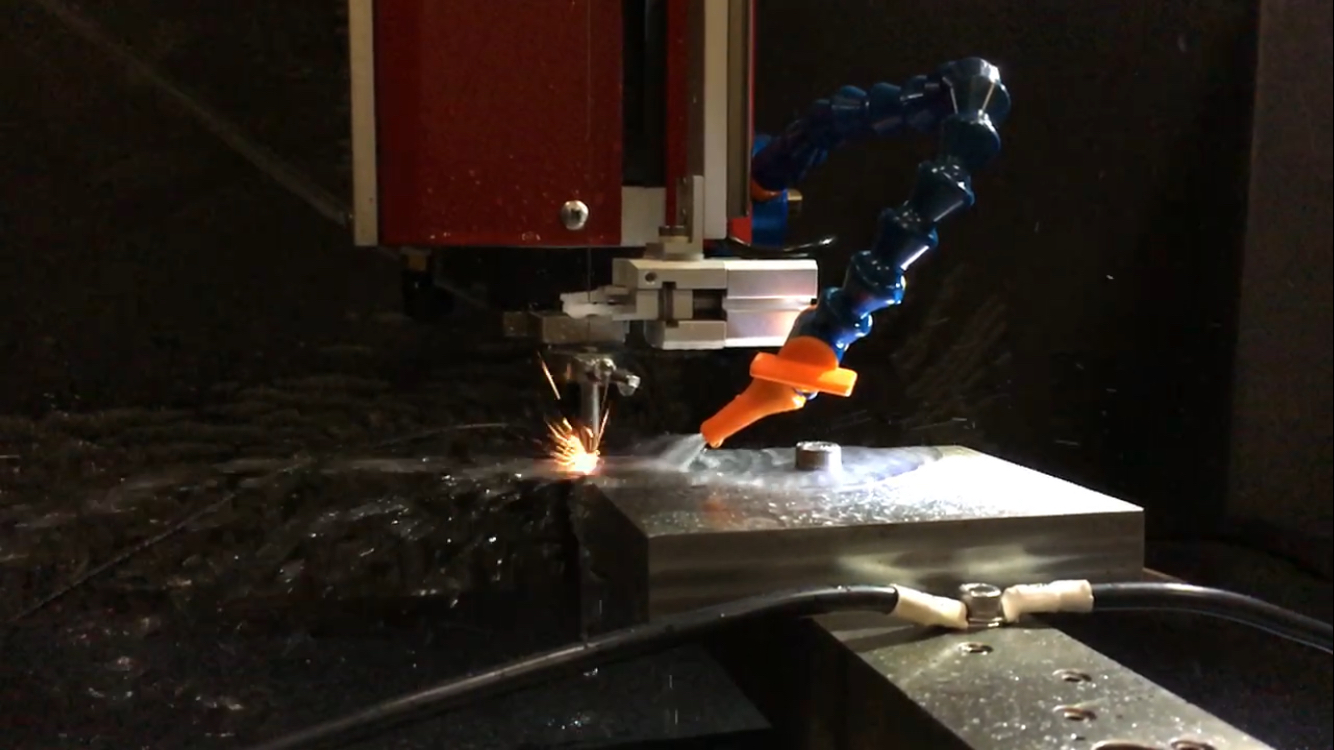

To put it simply, electrical discharge machining is a manufacturing process that uses electrodes to precisely remove material from a conductive material. In the small gap between the workpiece and the electrode, a discharge occurs which removes the material by melting or vaporizing. For this process, the electrode and the workpiece must be immersed in the dielectric fluid.

Why need EDM?

EDM has brought many benefits to manufacturing companies. The versatility provided by EDM in handling hard metals is a major advantage. It can be used to control the shape or physical properties of most materials. Using EDM, it is easier to machine harder metals, including hard metals such as titanium, tungsten carbide, and steel. In addition, EDM can be used to obtain a high precision profile on the workpiece, and when the discharge is triggered, they will heat the workpiece. The surface of the workpiece will become smoother and cleaner without the need for additional edge cleaning or deburring, which is usually desired by manufacturing companies.

Because of these advantages, EDM is often used in the aerospace and automotive industries for the development of high precision and advanced engine components.

The benefit of using EDM

•It can be used for small workpieces that are usually damaged by conventional cutting tools. In the EDM, the electrode is not in direct contact with the material, so it will not be damaged.

•Get better at making the geometrical shape you want

•Higher surface smoothness.

•Can create complex shapes that may be difficult to generate

By controlling many possible changes in the surface layer during the EDM process to ensure the product’s surface specifications and to produce a perfect product (i.e., without any surface damage), the quality of the product is ensured and the quality of the product is improved.

Overview of WEDM

Wire electrical discharge machining (WEDM) is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. WEDM is an unconventional process that works on parts that are resistant to conventional processes, but only if they conduct electricity. Usually, they are non-ferrous metals, including steel, titanium, superalloys, brass, and many other metals. Wires in Wire electrical discharge machining are usually molybdenum or copper. WEDM works by generating an electric discharge between the wire or electrode and the workpiece. When the spark jumps across the gap, the material is removed from both the workpiece and the electrode. To prevent a spark short circuit, a non-conducting fluid or dielectric should also be used. The waste is removed by the dielectric and the process continues.

Why use WEDM

Because this process can cut very small pieces, it is often ideal for producing small, high-detail projects that are often too fine-grained for other processing options. In addition, the process is cost-effective for a small number of projects and can prove beneficial to prototyping even when the actual project is done in a different way. This process produces incredibly accurate, high-quality cutting even on micron-scale parts. Cutting thin materials, intricate details and tight ribs can be done easily without burring. WEDM is best suited for projects with tolerances, material stress limitations, and high-quality requirements.

The benefit of using WEDM

No impact cutting – Machining hard materials usually requires a great deal of force and impact force to form the desired shape, and a great deal of force and impact can produce stresses that deform the material during cutting and rapid wear of tools. With Wire EDM, as long as the material conducts electricity, there is no impact or stress.

Easy to make complex shapes – Because the Wire EDM machine uses electrical discharges throughout a fine wire, it is easy to cut precise and complex shapes even in the hardest or most brittle materials. Because wires can form an infinite range of shapes, tiny Outlines and holes can be formed even without heating the material to soften and harden.

High tolerance – Line cutting is more accurate than laser, flame, or plasma cutting. It does not apply any force on the parts, thus enabling Wire EDM machining to achieve high tolerances for precise dimensions and exact fit. This eliminates the need for additional processing and finishing of the parts after processing.

WEDM can produce better molds and thus reduce costs. Because wire EDM processing can be used to efficiently process any conductive material, no matter how hard or brittle it is, the processing will take less time and can be done in one process. Therefore, we can also reduce waste. There is no need to heat treat or clean the parts after processing because the EDM wire cutting machine can easily cut through or even harden the material.