The quality of plastic parts plays an important role in the development of the automobile industry. The most important part of automobile mold is the covering mold. This kind of mold is mainly a cold die. In a broad sense, “automobile mold” is the general name of all parts of the mold manufacturing automobile, like stamping mold, injection mold, forging mold, casting wax mold, glass mold, and so on.

There is no essential difference between automobile injection molds and other injection molds, but it also has many characteristics of their own. Due to the high added value of automobile injection molds, many advanced technologies (such as sequential valve hot runner control technology, internal parting surface technology, low-pressure injection technology, etc.) are given priority to be developed and applied in the automobile injection mold.

- Sequence valve hot runner control technology (SVG technology)

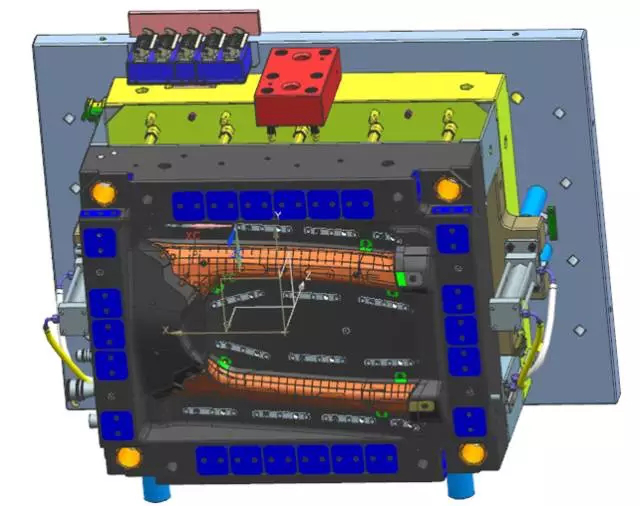

Sequential valve hot runner control technology (SVG technology) is a new type of cascade control hot runner technology, which solves the problem of appearance defects of traditional multi-point synchronous glue feeding products by controlling the sequence of glue feeding through the oil cylinder. It can effectively avoid the defects such as welding marks and cavitation, reduce the flow length and molding pressure and play a great role in the automotive interior and exterior trim with strict appearance requirements.

- Low-pressure double-layer injection mold technology

The low-pressure double-layer injection mold is also referred to as low-pressure injection mold, is a new type of injection mold technology, the traditional tech that relies on the manual coating, negative mold vacuum adsorption parts, directly one-time injection in the mold to complete. The main principle of low-pressure injection mold is: the injection pressure is a lower plastic flow on the cloth, the cloth must be hung to the front of the mold hanging needle, and then mold – injection – take. Using this technology to produce products, because the surface has a special layer of soft cloth, whether decorative, feel, aesthetic greatly improved. Therefore, the low-pressure injection mold technology is widely used in high-grade cars, generally used in the automotive map bag skeleton, automotive ABC column, and other parts.

- Injection mold technology for automobile bumper inner parting

For the automobile bumper product, the mold design usually USES the advanced inside parting surface technology. The advantage of this method is that the parting clamp wire is hidden on the non-exterior surface of the bumper. But this kind of technology in the difficulty and structure is more complex than the external parting bumper, the technical risk is also higher, the mold cost and the mold price will also be higher than the external parting bumper a lot, but because of its beautiful appearance, is widely used in high-end cars. In order to ensure that the inclined top and front die move synchronously in the process of mold opening, so that the product can be deformed and demoulded when the ejector mechanism moves synchronously with the front die for 60MM, the front/back die part is separated, so as to protect the mold and the product!