Let’s start with the conclusion:

If you want it to be fast and low-cost, mainly for appearance verification → 3D printing.

If you pursue high precision and strength → CNC machining.

If you need something close to the final use but with material limitations → Vacuum casting.

For functional verification, such as fire resistance, waterproofing, and high-temperature resistance → Prototype injection molding.

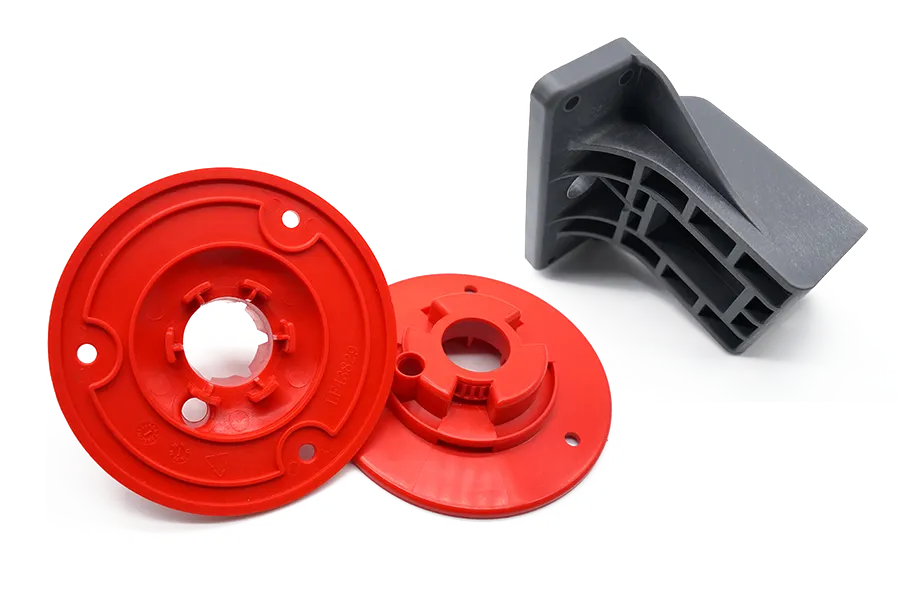

In the process of new product development, plastic prototype molding not only helps designers verify appearance and function, but also allows companies to discover potential problems before mass production, reducing risks. So, when facing multiple options such as 3D printing, CNC machining, vacuum casting, and prototype injection molding, which process should be used for plastic prototype molding?

As an engineer with more than 15 years of experience in injection mold engineering, I will analyze the characteristics and application scenarios of different processes here based on real projects.

Why make plastic prototype molding?

Before investing in mass production injection molds, prototype samples have several core values:

- Risk reduction: Identify structural or material issues in advance and avoid costly mold rework.

- Function verification: Ensure that parts perform reliably in terms of strength, assembly, and usage environment.

- Market testing: Use small-batch samples for customer validation or trade show displays.

- Shorter cycle: Promote design optimization and market feedback in parallel to accelerate time-to-market.

Therefore, choosing the right prototype molding process is a key step to successful mass production.

Common plastic prototype molding processes

- 3D Printing (Rapid Prototyping)

- Advantages: Fast speed, low cost, suitable for early concept verification. Complex structures can be formed without additional processing.

- Disadvantages: Limited mechanical properties of materials, cannot fully represent real injection-molded parts.

- Applications: Appearance models, assembly verification, early design iterations.

- Advantages: Can directly machine engineering plastics, high precision, strength close to final products.

- Disadvantages: High cost for complex structures, cycle time longer than 3D printing.

- Applications: Low-quantity needs, functional testing, strength verification, parts with high precision requirements.

- Advantages: Quickly replicate parts through silicone molds, appearance and feel close to finished products. Cost is lower than injection molding.

- Disadvantages: Short mold life, generally only able to produce dozens of pieces.

- Applications: Market testing, exhibition samples, small-batch functional parts.

- Advantages: Uses aluminum or soft steel molds, can produce parts almost identical to mass production. Surface finish, strength, and assembly precision can all be fully verified.

- Disadvantages: Mold cost and cycle time are higher than the previous processes, usually requiring 2–4 weeks.

- Applications: Small-batch needs of over 100 pieces, certification testing, final verification before mass production.

Engineer’s Experience Sharing

In my past client cases, many people often asked: “Can we skip the prototype stage and go directly to mass production molds?”

My answer is usually no. Because mass production molds often cost hundreds of thousands, and if there are problems in product design, each modification not only takes time but also brings huge financial losses.

I usually advise clients:

- Concept design stage: Use 3D printing for quick verification.

- Functional verification stage: Use CNC machining or vacuum casting.

- Pre-mass production verification: Choose prototype injection molding to simulate real production environments.

This phased strategy can balance time, cost, and risk.

How to choose the right plastic prototype molding process?

When choosing a process, the following factors need to be considered comprehensively:

- Quantity demand: Is it a few pieces, dozens, or hundreds?

- Material requirements: Must it be consistent with mass production materials?

- Testing purpose: Is it for appearance display, functional verification, or certification testing?

- Budget and cycle: Is the budget limited? Is the lead time urgent?

Once the above four points are clear, the appropriate solution can be selected. If you are still unsure, please contact us immediately for further assistance.