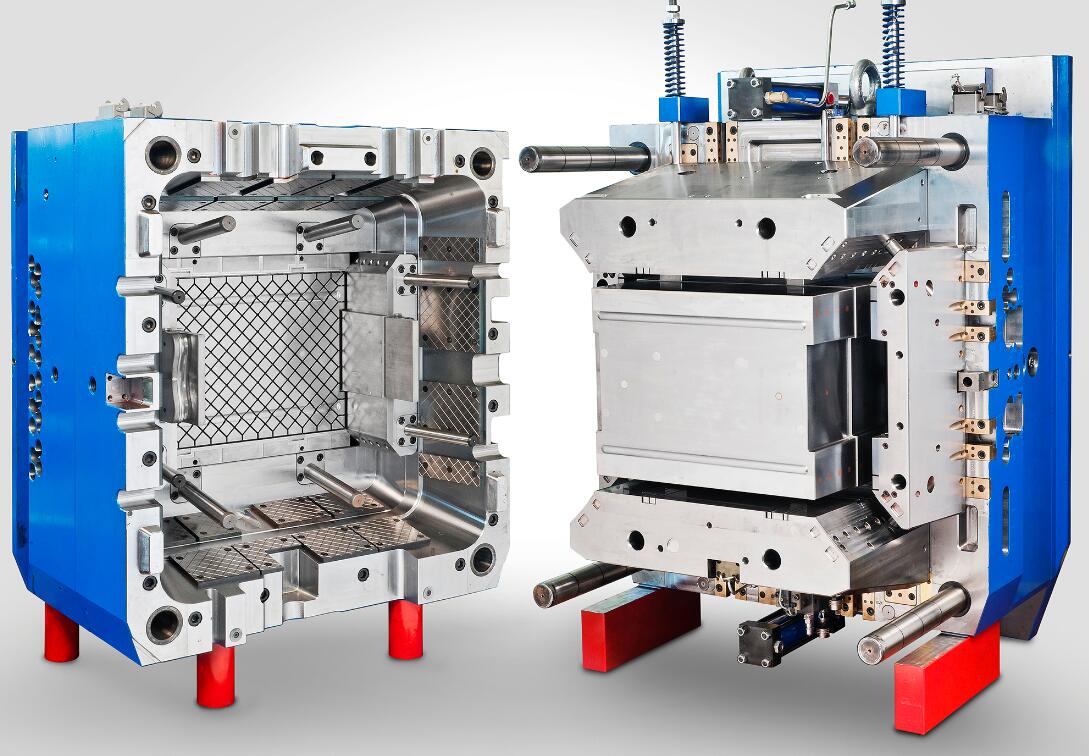

After completing the construction of the new injection mold, you also need to set up the injection mold for testing or molding the plastic.

Here are some things to note when setting up an injection mold:

Opening and trying all movements

In this step, we will perform die closing and die opening tests on the mold. In the mold closing test, we mainly measure whether the die is closed during the die closing movement, and observe whether there is a gap or too close when the die is closed so that the air in the cavity and core cannot be discharged. In the mold opening test, we mainly observe whether the mold is open smoothly, whether each part is separated smoothly, and whether the product can fall off smoothly in the mold. If the above problems occur in the test, the mold needs to be considered for rework.

Mold heater/cooling

These connections are required to bring the injection mold to the required process temperature by adding or removing energy from the mold. To achieve the process temperature a medium, water or oil is directed in circuits through the mold, one in and one out connection is called a set. After connecting and turning on the mold heater/cooler, you can check the working condition of the heater or cooler by manually checking whether the temperature has increased or decreased at all connections connected to the mold.

Mold temperature

The mold temperature is tested to determine whether the mold will deform at a certain temperature or what temperature it can withstand. In the hot mold, if the mold has high-temperature tolerance, then you can reduce the plastic condensation in the cavity so that the molten material flows more easily in the cavity so that the surface quality of the product will be better.

Hot runner setting

If the injection mold design has a hot runner system, we will check the nozzle orifice size. Excessive nozzle orifice sizes lead to excessive or inconsistent pressure, which burns the material and creates silver streaks on the parts. To avoid this problem, it is necessary to ensure that the nozzle radius of the molding machine is the same size as the nozzle base radius of the manifold. Adjust the machine nozzle hole size to match the pressure drop and allow more material flow, thus preventing burn mask and streaking problems.