Among the most innovative manufacturing industry in China and all over the world today is the automobile industry. In its efforts to improve security, boost fuel effectiveness, usage alternative fuels, and minimize ecological impacts, vehicle producers are relying more than ever on injection-molded plastic parts and items to accomplish these goals.

That’s why engineers from major automobile OEMs rely on RJC to solve their hardest design challenges – these consist of product choice and efficiency, style for manufacturing, prototyping, mold design, tolerance, and quality assurance.

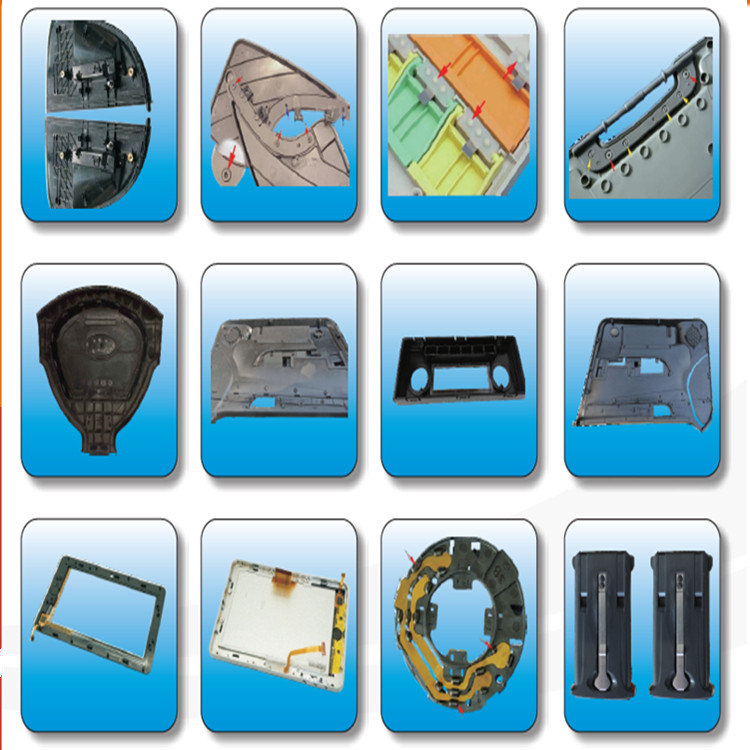

Specialists in Critical Use Plastic Part Design

As automobile industry injection molding technologies continue to improve, parts are ending up being increasingly complex in style, with tolerances as tight as 0.001 inches. Depending on end-use, a lot of these plastic parts and items must stand up to severe, under the hood operating environments. More than 20,000 resins are readily available today that have actually been engineered to supply particular physical qualities such as strength, flexibility, temperature, rust, and UV resistance. RJC engineers share their extensive knowledge of material science to help clients choose the very best plastic for achieving their efficiency objectives (and even on a lower budget).

As a result, RJC manufactures complicated parts and products that are crucial to the efficiency of braking systems, cooling systems, fuel shipment systems, and the power train. The details for these items are often figured out through style for manufacturing research studies. RJC at the same time use our extensive product science and injection molding understanding to style and manufacture the very best possible item, in the most efficient method.

Manufacturing and Designing Tight Tolerance Customized Parts for the Automotive Industry for over 15 years

We are also professionals at metal to plastic conversion. This ingenious method enables OEMs to decrease lorry weight and increase fuel performance by replacing heavy metal parts with identical but lighter-weight plastic parts that are just as long-lasting. This helps OEMs satisfy emission requirements and minimize general functional costs.

Mission-critical automotive part manufacturing is progressively complex to style and needs to fulfill precise performance standards to supply a safe driving experience. Using sophisticated technologies, finest practices, and advanced quality assurance systems enable RJC to supply economical options for the hardest vehicle engineering obstacles.

Reply to RJC to ensure your product and parts’ quality. If you are searching for excellent quality, much better efficiency, and also undeniable precision for your injection molded vehicle parts, definitely RJC Molding is the supplier to depend on. You could contact us today by calling our tel number 0086-755-27693385 or send us an e-mail to engineers@rjcmold.com.