Rjcmold’s Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

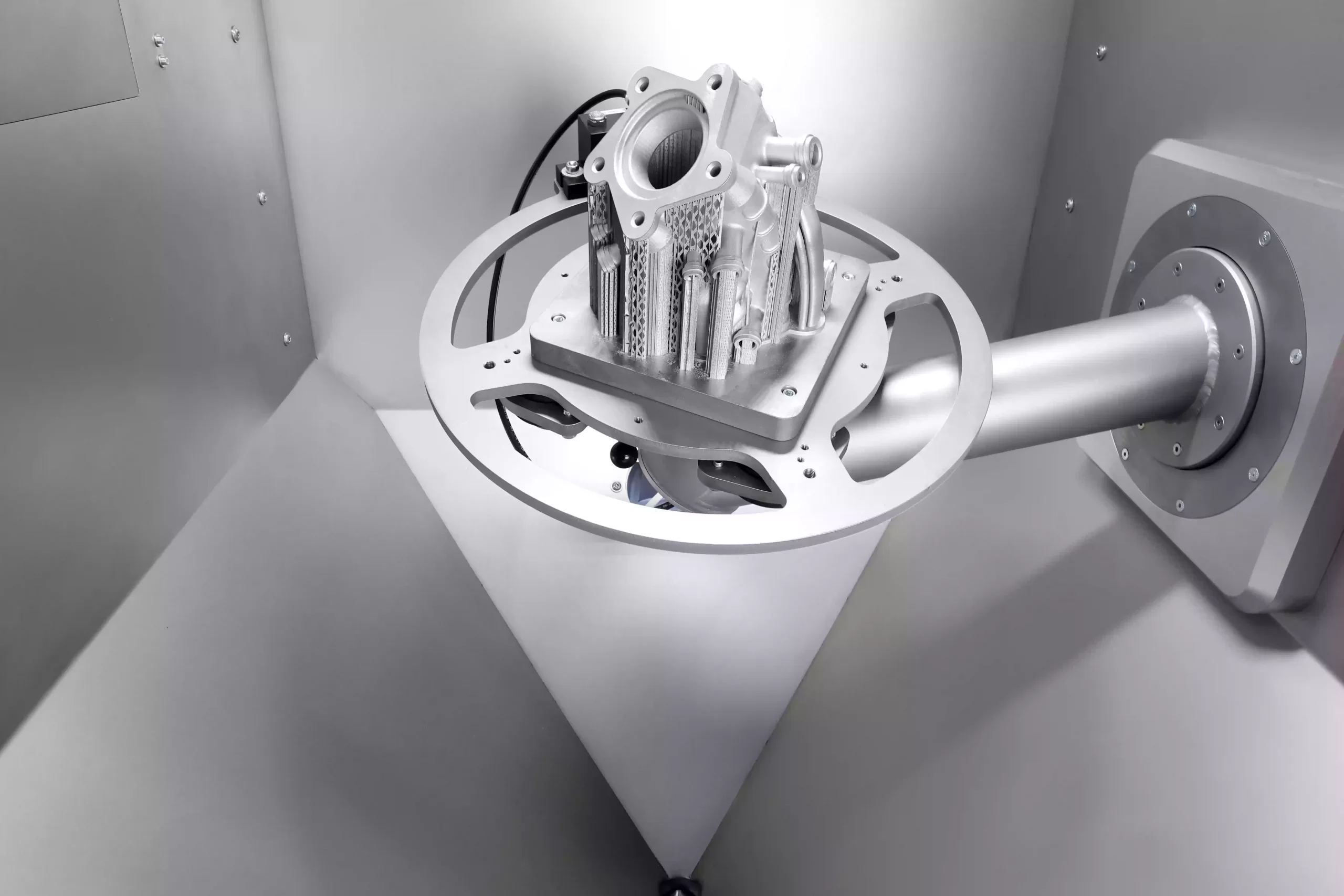

Our online 3D printing service enables you to 3D print your custom part on demand. We use the latest additive manufacturing technology to build affordable, functional parts in over 60 metals and plastics.We offer three 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

Advantages of 3D Printing

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, machining, or casting.

- Complex, organic geometries with limited impact on part cost

- Consolidation of multi-component assembly into a single part

- No upfront tooling costs

- Fast production for parts within 24 hours

- Internal features for advanced heat transfer and flow applications

CERTIFICATIONS

ISO 9001:2015 | AS9100D | ITAR Registered

100,000+

Parts printed each month

30,000+

Product developers served

130+

Additive manufacturing machines

Our online 3D printing services

With the help RJCmold’s online 3D printing service, your parts are manufactured to the highest standard of large-format additive manufacturing.

Whether you’re a rapidly growing business reaching to meet increasing demand or a new endeavor yet to invest in industrial additive manufacturing equipment, RJCmold’s large-format 3D printing service will boost your productivity and help seamlessly deliver your work at its best.

Available 3D Printing Materials

New to our 3D printing services and not sure which additive technology is right for your 3D designs? Below each material, see which ones fit the requirements of your application.

Aluminum

Copper

Stainless Steel

Titanium

ABS

PA (Nylon)

Polycarbonate

Polypropylene

Digital photopolymer

TPU

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

| Part Size | RJCmold can accommodate 3D printing up to 24″ x 36″ x 36″ without the need to split and bond parts. |

| Minimum Feature Size | 0.030″ – 0.060″ is typical. |

| Minimum Wall Thickness | 0.020″ – 0.060″ is typical. |

| Clearance Between Features | At least 0.030″ |

General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out RJCmold’s Manufacturing Standards for more information on tolerances per process.

“Excellent service at a reasonable price, Start Your Project With A Free Quote”

– RJC

Our 3D Printing Service Includes Custom Finishing

Looking to boost the strength, clarity, or appearance of your 3D-printed parts? Choose from microfluidic and micro-resolution materials, metal plating, secondary machining, and custom finishes like painting, clear coating, and decaling.

| Name | Description |

|---|---|

| Clear Coat | Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials. |

| Painting | After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting. |

| Plating | Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium. |

| Dyeing | Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting. |

| Decaling | Decaling can be used to add a logo or other graphics to boost cosmetics or function. |

| Polishing | We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations. |

| Heat Treatment | Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging. |

| Machining | Machine metal 3D prints to achieve exceptional surface finish quality or meet tight tolerances. |

Why Choose RJC for 3D Printing?

Reduce your cost

Although 3D printers require power to operate, there is generally no material wastage involved. Subtractive processes like machining, on the other hand, produce waste material. Since 3D printing uses only the required material and needs no tooling, it is one of the most affordable manufacturing processes for one-off parts or small batches.The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

Wide Materials Selection

Across our three 3D printing technologies, we use a range of commercial-grade thermoset resins, and thermoplastic and metal powders to 3D print parts that are suitable for various part applications and industries. If required for your parts, we offer a variety of post process options such as heat treating, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

Consultative Quotation

Get design feedback from our RJC experienced and professional engineering team that has helped thousands of customers bring their products to market with high quality 3D-printed parts. We will also work with you to determine optimal parts orientation based on your application’s needs.

Flexible production

RJC has 3D printing machines that produce metal and plastic parts of your projects wheather it’s a small batch and mass production. Once a part has been designed using CAD software, it can be printed in a matter of hours, without a lengthy setup procedure for your rapid prototypes. 3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.Because of the feature of 3D printed parts require no tooling, there is less risk involved when producing a part. If a flaw is discovered after printing, it can be amended digitally without replacing expensive tooling.

Precise and Professional

Our leading industry tolerances and surface finish quality stems from a dedicated process engineering and quality team for each 3D printing or addictive manufacturing technology. The high precision and conformity of 3D printing makes it an ideal way to build production quantities of separate or customized parts.

Common 3D Printing Applications

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace, medical, automotive, and other large industry sectors. Examples of typical parts, include:

- Form and fit prototypes

- Housings and enclosures

- Medical devices

- Snap fits

- Jigs and fixtures

- Heat exchangers and heat sinks

- Engine components

- Fuel injectors

- Surgical instrumentation

Our online 3D printing service makes your 3D models a reality!

Upload your 3D file to get a free instant quote!

Upload your 3D file to get a free instant quote!

Select the 3D printing material and finishing options you need, and let our professional 3D printing service handle the rest. Your parts will be manufactured in our 3D printing factory and delivered to your door in a matter of days. Be at the forefront of innovation and get your 3D printed parts today.