Rapid Prototyping service

If you are working on a new product or refining an existing one, rapid prototyping is ideal to test, iterate and adjust your concept. This is a way to speed up your designing process and bring your ideas and product to market faster.

Do you need parts as quickly as possible to validate a project? We will manufacture your parts immediately in our factory-certified ISO 9001.

Rapid prototyping: A quick and efficient way to give life to your ideas

Rapid prototyping allows you to create a physical model of your product or design a concept quickly and efficiently. 3D printing offers a range of technologies and materials adapted to rapid prototyping. You can then test and validate your ideas before committing to full-scale production. 3D Printing is the shortest path between your ideas and a functional prototype in your hands and it can be used at each stage of your manufacturing process. More specifically, 3D printing can be a strong ally at the early stages of your product development. With 3D printing technologies, make as many iterations as needed with a great precision and speed up your prototyping process.

From Rapid Prototyping to Production

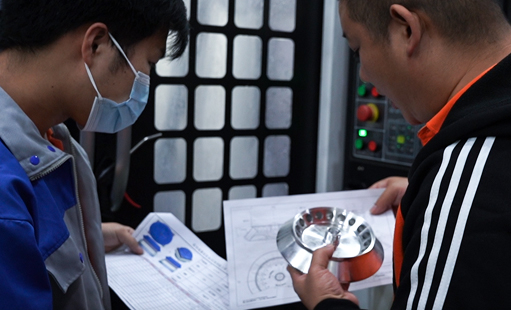

Having been in the prototyping and production industry since 2003, we help startups and established brands manufacture prototypes and products that compete favorably in the global market. This is a testament to the quality and precision of our machines and a seasoned team of professionals working tirelessly to ensure your top-quality products get to the market as when due.

At RJCmold, we offer top-notch services that encompass all aspects of manufacturing, from prototyping to production. Our rapid prototyping services include injection molding, rapid 3d printing services, CNC rapid machining services, plastic extrusion, and sheet fabrication, considering your ideal prototyping material. Our rapid prototyping and production services considerably cut the production cost for you while reducing the time to market. So work with us today for all your prototyping to production needs.

Our Rapid Prototyping Capabilities

Consider the following chart when deciding which Rapid Manufacturing service is best for your project:

| Process Type | Function | Fit | Testing | Proof of concept | Tolerance <.005 in | Visual Quality | Plastic Material Selection | Metal Material Selection | Per Piece Price | Tooling Cost | Tooling Life Expectancy |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3d Printing | Limited | Yes | no | Yes | Limited | Limited | Limited | Limited | High | N/A | N/A |

| Injection Molding | Yes | Yes | Yes | Yes | Yes | Yes | Unlimited | Limited | Low | Low-

Mid |

Unlimited |

| CNC Machining | Yes | Yes | Yes | Yes | Yes | Yes | Limited | Unlimited | High | N/A | N/A |

| Cast Urethane | Yes | Yes | Yes | Yes | Limited | Limited | Limited | N/A | High | High | < 50 |

Start your rapid prototyping project today

Our engineers are always ready to work with you to ensure you get a quality product quickly. When you submit a 3D design file, we will negotiate with you to ensure the manufacturability of the design, resulting in a product that meets and exceeds your expectations. Contact us today for a free quote and design review.

Advantages of Rapid Prototyping

Rapid prototyping services can confer abundant benefits for you and your business. Its outstanding advantages are as follows:

How May We Help You?

As your rapid prototyping services partner, we are committed to optimizing your product design and testing speed and accuracy with a broad range of 3D printing materials, technologies, knowledge and resources.

Design feedback

- Receive interactive design for manufacturability feedback and each quote so that adjustments can be made early before prototyping begins.

- Talk to application engineers about any design challenges and manufacturing issues that arise.

Iterative development

- You can have a physical prototype within a few days to quickly modify the design during early product development.

- Produce multiple prototypes simultaneously to compare and iterate designs simultaneously.

- Reduce time to market through iterative product development cycles.

Design verification

- Test the shape and fit of the assembly with a small number of molded parts.

- Perform functional tests using prototypes made of production-grade materials.

- Complete online design resource library, including guides, tips, whitepapers, and videos.

Market test

- Production of pre-produced injection molded parts to validate market benefits prior to launch.

- Reduce the financial risk of going to market by implementing reasonably priced aluminum tools before mass production begins.

Prototypes and Parts Delivered Fast with 4 Simple Steps

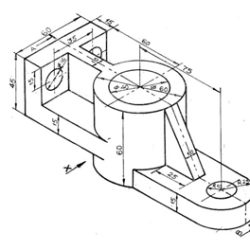

Upload a CAD File

To start, simply fill in a few information and upload a 3D CAD file.

Quote & Design Analysis

You’ll receive a quote shortly, and we’ll send you design for manufacturability (DFM) analysis if necessary

Order Confirmation

Once you review the quote and place your order, we’ll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

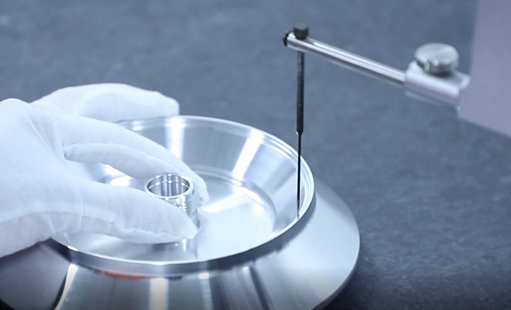

Your prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep

Material Options for Rapid Prototyping

We provide quotations for over 100 metals and plastics for your prototyping needs. On our platform, you can also view the different materials and the cost of their machining.

Why Rapid Prototyping Services With RJCmold?

Our prototyping services take a full cover of an extensive range of complementary services, including CNC machining, 3D printing, plastic injection molding, vacuum casting, and all kinds of finishes. Besides, we have an experienced engineering team, they accumulate huge manufacturing experience from thousands of solid projects. We are confident that we are an excellent manufacturing provider, we can create any custom parts based on customer’s requirements. No matter how high a requirement for shape and tolerance, we can come out with a solution.

First, our Manufacturing services cover a lot of materials, the typical types are aluminum, stainless steel, ABS, silicone, rubber, polycarbonate.

Secondly, we are flexible for MOQ. We are happy for 1 off single part, we also ok for volume production with 10000+ pieces. No matter the size of the order, we can handle it.

Lastly, we have a mature quality system with comprehensive quality-control processes. It covers each manufacturing step, including material, machining process, assembly process, and shipment.

In a word, we are the ones who can support you with a professional prototyping service, help actualize your ideas, improve your design, and assist with product development.

Since we are one of the trusted manufacturers of prototyping and low-volume manufacturing in China, we will glad to inform you RJCmold will absolutely help you to skyrocket your business when you come to us.

Request Your Free Rapid Prototyping Quote Today

Ready to get started? Contact us with details of your project to take advantage of our automated electronic quoting service, design verification process and excellent customer feedback program. With an extensive amount of finishing options to compliment a wide range of material types, over 100 CNC machining centres、3Dprinting、injection molding and deeply-rooted industry experience, RJCmold is always willing to collaborate and deliver functional end-use parts with quality you can trust every time.