Customized Extrusion Moulding Parts Service

We offer a customized extrusion moulding parts service to meet your specific needs. Our team of experts can work with you to design and produce high-quality parts that meet your exact specifications. We use state-of-the-art machinery and advanced manufacturing techniques to ensure that every part we produce is of the highest quality. Contact us today to learn more about our extrusion moulding parts service.

Extrusion Moulding Parts Manufacturers

Rjcmold has a very versatile and wide range of extrusion molding capabilities. Small custom orders as well as large volume orders can be produced with a surprisingly short lead time. Whether you require a custom profile with a metal or specialized compound, or just some standard EPDM cable jacket, let Rjcmold be your one stop solution for extrusion molding.

With our on-site mold shop, we can create any form out of aluminum or steel for life-long use of the mold. We also perform soft tooling out of urethane or plastic for prototyping of molds or short-run manufacturing of parts.

The quality systems of Rjcmold. have been certified to the ISO 9001:2015 Standard, and we use Lean Manufacturing and other cutting-edge methods to ensure that your parts are of the highest quality, made on time, and meet specifications the first time. We also offer rapid prototypes of your custom parts in days by utilizing our in-house lab with our 3D printer.

Customized Extrusion Service

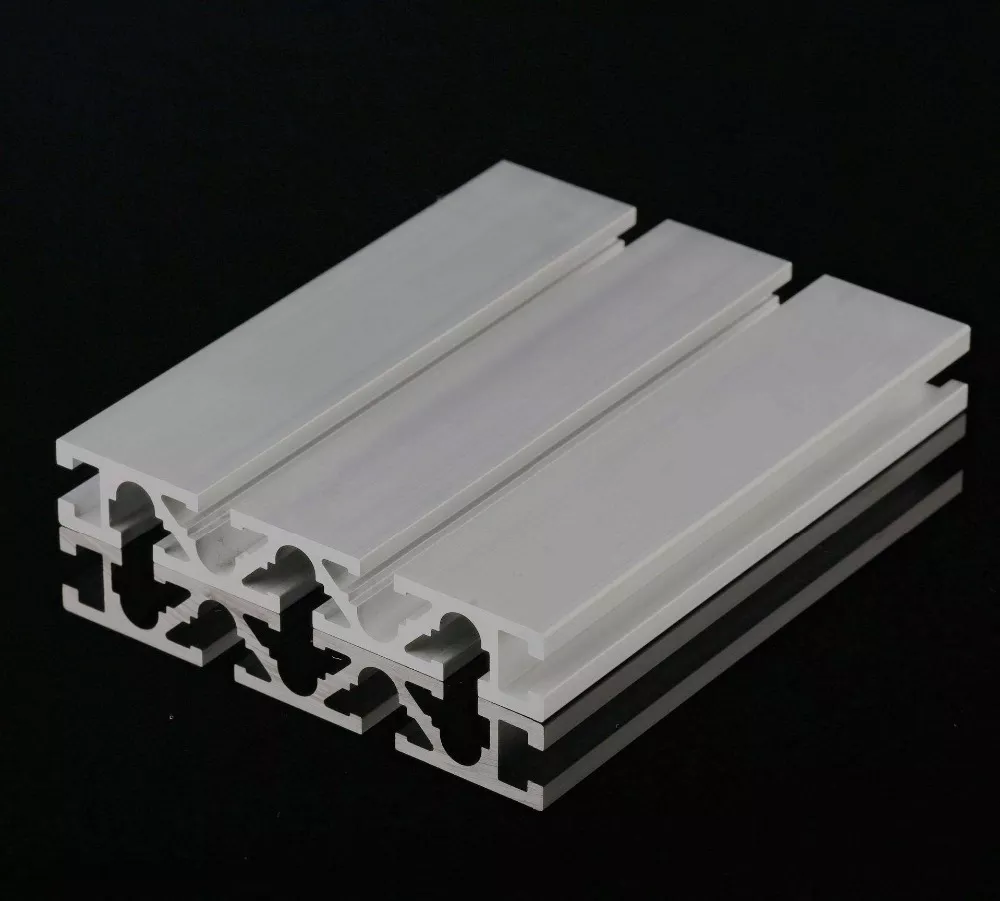

Extrusion is the process of shaping material, by forcing it to flow through ashaped opening in a die.Extruded material emerges as an elongated piece with the same profile as the die opening.

For commonly used extruded parts, you can source it from the marketdirectly, but for special shapes or other extruded parts for industrial use that are not on the market, Rjcmold can customize and manufacture them for you.

In order to save costs for you, we usually use the following two methods to make extruded parts for you,

Our Extrusion Moulding Manufacturing Capabilities

At our manufacturing facility, we specialize in extrusion molding for a variety of industries. Our state-of-the-art equipment and experienced team allow us to provide high-quality products and excellent customer service.Whether you need extrusion molding for packaging, automotive, or any other industry, we are equipped to meet your needs. Contact us today to learn more about our capabilities and how we can assist with your project.

Surface Finishing Options for Extrusion

In addition to customizing the shape and do secondary processingfor your extruded parts, we can also provide you with a variety of surface finishes as below, they can also be different colors and textures.

● Basic finishing(deburring, sanded smooth, sandblasting, polishing and so on)

● Painting

● Anodizing

● Plating(Chrome, Nickel, Zinc plating)

● Powder coating

● Silkscreen, pad printing, water transfer

● Laser engraving

Advantages of Extrusion at Rjcmold

● No MOQ at Rjcmold, we can make prototype, low-volume production or big-volume production for you.

● We can customize part according to your needs and keep the mold at Rjcmold for future orders.

● Provide other supporting services, such as CNC post-processing, bending, surface finish and overmolding etc.

We provide one-stop service for your project instead of to complete it with different partners, so that you can better manage your project and receive it more faster and higher quality.

Solutions by Industry

- Aerospace

- Architectural

- Automotive Aftermarket

- Automotive Restoration

- Building & Construction

- Chemical Processing

- Electronics

- Food Processing

- General Industry

- HVAC

- Medical

- Marine

- Material Handling

- Oilfield & Refinery

- Rail & Mass Transit

- Refrigeration

- RVs and Sport Vehicles

- Pool & Spa

- Solar Panels

- Sound Studios

- Transportation

- Window & Door Seals

We can work with you to determine the specific needs of your project or industry so we can deliver the quality, reliability, and pricing that your project needs to succeed.

We will take the time to understand the demands of the product, the requirements and standards of your industry, and then make recommendations for the right materials, suggest design alternatives, and help you consider all the additional factors that may have an impact on the results.

As an experienced custom manufacturer, you can rely on our depth of experience to produce top quality extruded metal or plastic parts that exceed your expectations, from standard tubing to highly intricate and complex shapes. We can even accommodate high and low volume production with equal efficiency through careful use of resources.

Contact us today to learn more about extrusion molding and how we can fulfill your needs.