Stainless Steel CNC Machining Services

Manufacturer of custom stainless steel parts

Known for its excellent corrosion resistance, heat tolerance, and high strength-to-weight ratio, stainless steel is used in aerospace, medical devices, food equipment, and automotive components.

At RJC, we provide stainless steel CNC machining services, working with grades such as 304 and 316L to achieve tight tolerances, superior durability, and consistent performance for both prototypes and production runs.

Our CNC Stainless Steel Machining Capabilities

We offer comprehensive CNC machining services for Stainless Steel, ensuring tight tolerances and smooth surface finishes:

- Processes: CNC milling, CNC turning, 5 Axis CNC machining

- Tolerance: Down to ±0.01mm or tighter on request

- Part Size: Up to 1000 × 600 × 400 mm

- Volume: 1 to 5,000+ parts

- Supported Files: STEP, IGES, DWG, Parasolid, STL

All parts are inspected using precision metrology tools and supported by engineer-led design for manufacturability (DFM) feedback.

Advantages of stainless steel

Suitable for customizing durable and corrosion-resistant metal parts.

Industries We Serve

Suitable for all industries requiring precision stainless steel parts.

Common Stainless Steel Grades We Work With

| Grade | Features | Common Applications |

|---|---|---|

| 303 | Easy to machine, good for general use | Fixtures, shafts, uts |

| 304 | Corrosion-resistant, food-grade safe | Medical housings, kitchenware |

| 316 | Superior corrosion resistance, marine-grade | Medical implants, pumps, marine parts |

| 17-4 PH | High strength, heat-treatable | Aerospace, automotive, tooling |

| 410 | Heat-resistant, hardenable | Valves, fasteners, bushings |

Need help choosing a material? We’re happy to advise based on your application.

Surface Finishing for Stainless Steel Parts

Enhancing durability and appearance with custom stainless steel finishes.

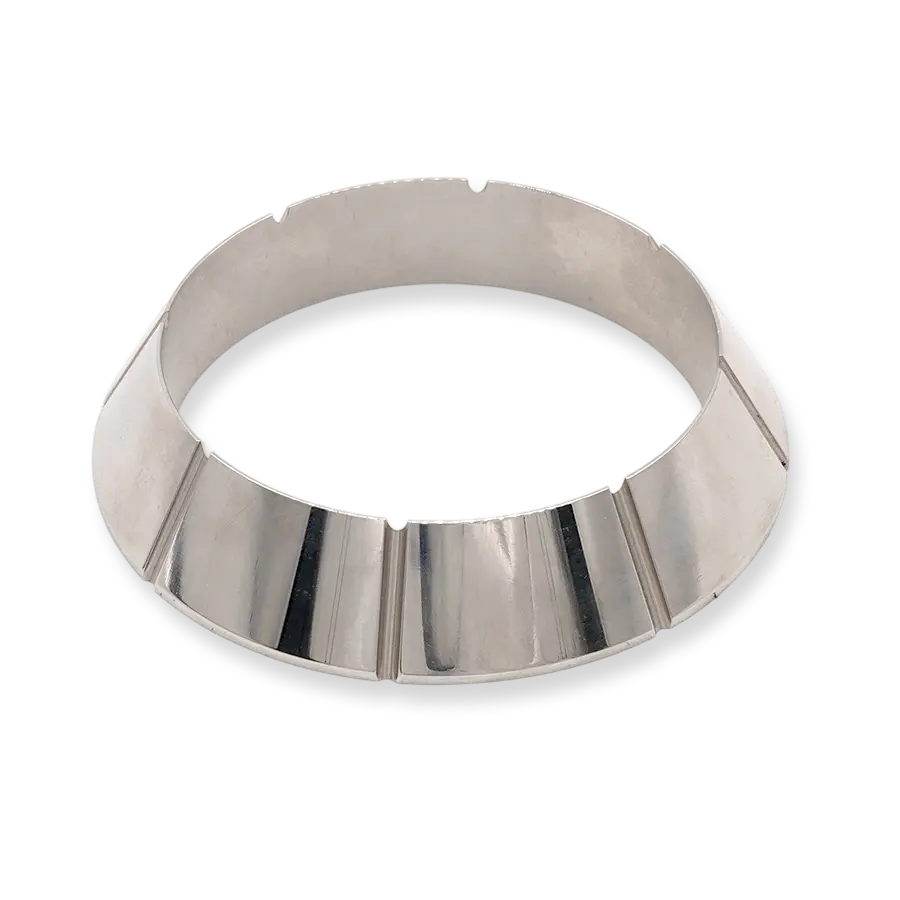

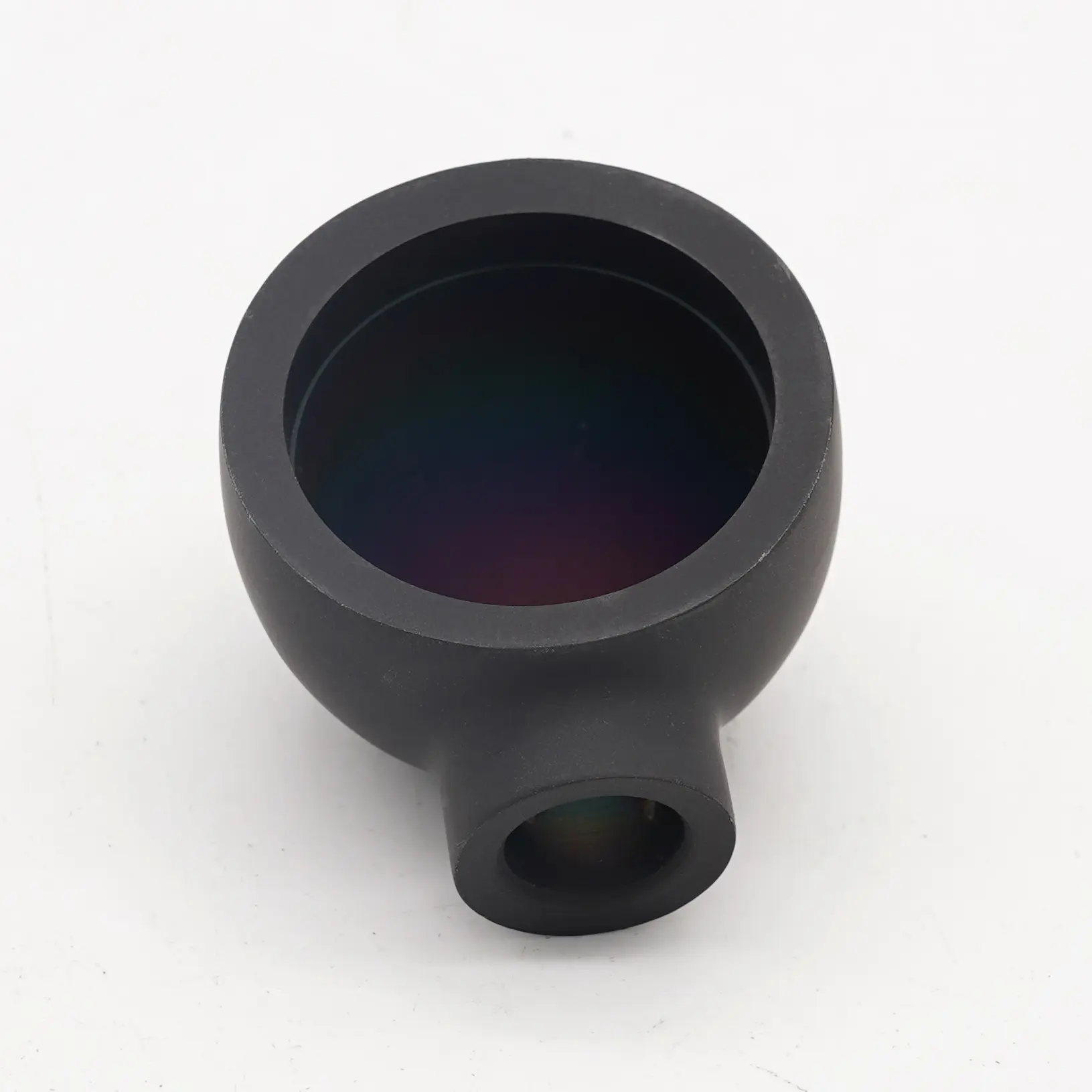

Stainless Steel CNC Parts We Manufacture

Why choose RJC for Stainless Steel CNC Machining?

- CNC machining manufacturer with over 20 years of experience

- ISO 9001 certified facility

- In-house quality control with full inspection reports

- Fast lead time — 3 to 5 days for prototypes

- Engineer-reviewed DFM suggestions

- NDA protection for every customer

We understand global buyer needs — from quality expectations to shipping and customs — and help you receive reliable parts on time.