HDPE CNC Machining Service

Get custom HDPE parts with excellent chemical resistance and smooth machinability — precision-made and shipped worldwide.

✔ ISO 9001–certified quality management

✔ From prototyping to full-scale production

✔ Tolerances as tight as ±0.05 mm

✔ Typical lead times of 5 days for most orders

What We Offer for HDPE Machining

HDPE is widely used in water treatment, packaging, and food handling due to its excellent chemical resistance and impact strength. But its low melting point and high flexibility can lead to chip entanglement, part distortion, and difficulty in holding tolerances — making professional machining control essential.

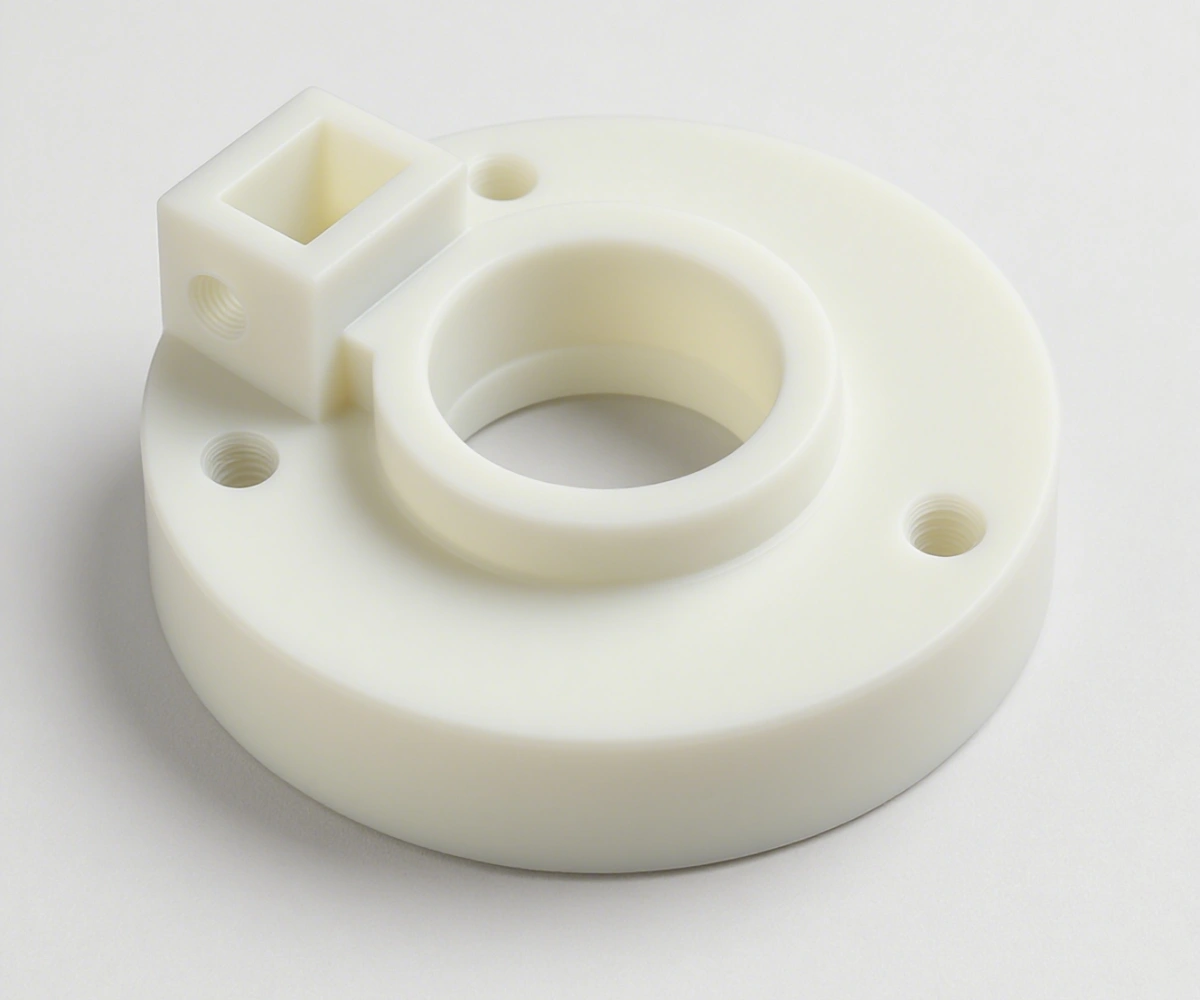

CNC Milling for HDPE

Milling is ideal for producing HDPE parts with flat surfaces, cavities, and complex profiles — such as:

- Fluid trays and equipment covers

- Lightweight panels and protective housings

- Custom brackets and valve blocks

To ensure clean results, we use:

- Sharp polished cutters to reduce friction

- Low cutting speeds to avoid thermal deformation

- Fixturing strategies to stabilize flexible parts during milling

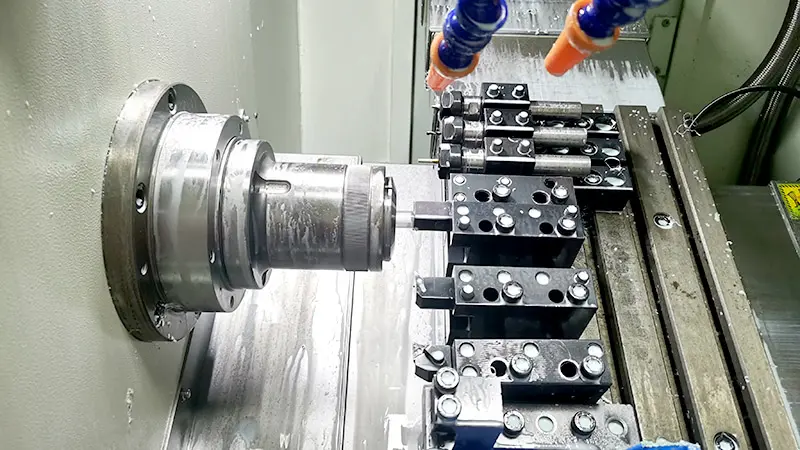

CNC Turning for HDPE

Turning is commonly used for round HDPE components like:

- Spacers, bushings, and pipe fittings

- Low-friction sleeves and washers

- Food-safe rotating parts

Our turning process includes:

- Fine-tuned tool geometries to reduce edge tearing

- Stable clamping setups for consistent concentricity

- Deburring and trimming to ensure surface integrity

HDPE CNC Machining FAQs

For most parts, we can achieve tolerances up to ±0.05 mm. For tighter specs, we’ll assess feasibility based on geometry and function.

HDPE parts usually have a clean, matte finish straight off the machine. We also offer optional edge smoothing, deburring, and polishing. However, due to HDPE’s low surface energy, it’s not suitable for painting or coating without pre-treatment.

Send us your part design — we’ll help you compare HDPE with alternatives like polypropylene, UHMW, or ABS, based on your performance and cost needs.

It depends on your application. HDPE is impact-resistant and durable, but it’s relatively soft and flexible — better suited for low-load, non-precision assemblies.