PEEK CNC Machining Service

Get high-performance custom PEEK parts with outstanding thermal stability, chemical resistance, and mechanical strength — precision-machined and shipped worldwide.

✔ ISO 9001–certified quality management

✔ From prototyping to full-scale production

✔ Tolerances as tight as ±0.02 mm

✔ Typical lead times of 5 days for most orders

What We Offer for Brass Machining

When performance matters most — like in aerospace insulation components, surgical tools, or chemical-resistant seals — PEEK (Polyether ether ketone) offers one of the best strength-to-weight and thermal durability ratios among engineering plastics.

It withstands continuous use up to 250°C, resists most chemicals and radiation, and maintains mechanical integrity even under high loads — all while being remarkably lightweight. But machining PEEK is not simple: its high hardness, low thermal conductivity, and internal stress require professional-grade control.

We specialize in CNC machining PEEK to meet demanding industrial specs — with dedicated strategies for tool selection, fixturing, and heat management to avoid warping, chipping, or surface defects.

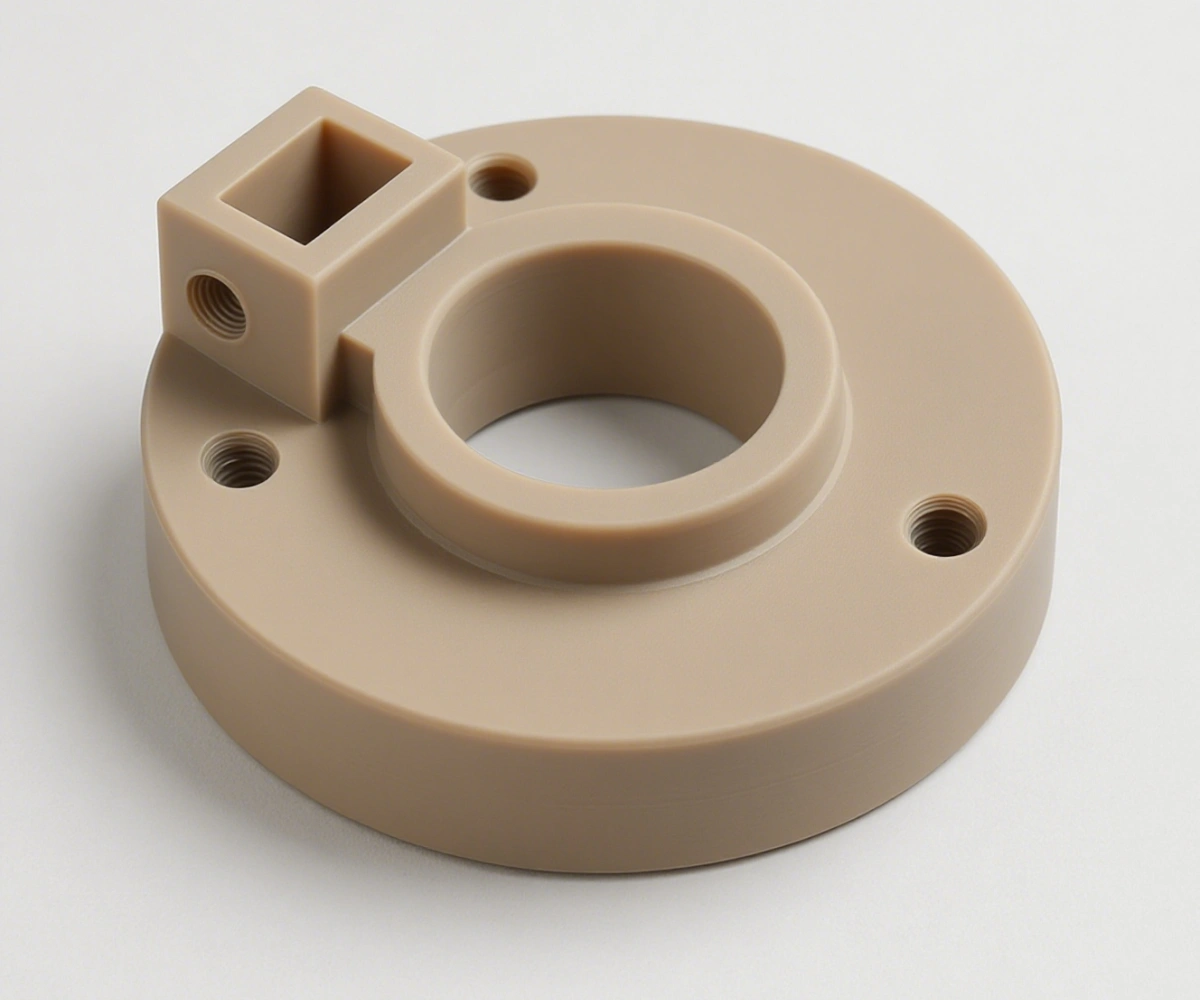

CNC Milling for PEEK

PEEK is ideal for milled parts that require precision and durability, especially with complex geometries or thin-walled structures. Common applications include:

- High-temperature housings

- Custom flanges and insulators

- Precision medical or fluid-handling components

Our PEEK milling practices include:

- Hard alloy tools designed for thermal stability

- Multi-pass toolpaths to minimize internal stress buildup

- Controlled cutting speeds to avoid melting or surface degradation

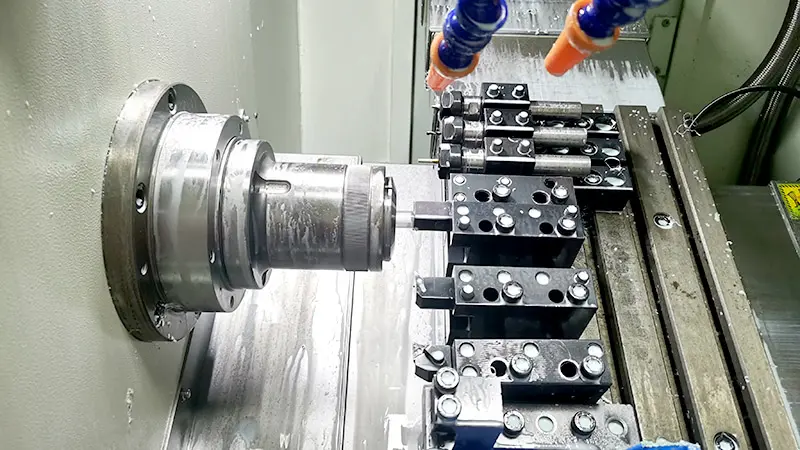

CNC Turning for PEEK

For cylindrical parts like valve seats, bushings, or insulative sleeves, turning PEEK can deliver high dimensional consistency — but demands close attention to setup and thermal control.

Our turning capabilities feature:

- Low-vibration clamping setups to prevent micro-deflection

- Sharpened inserts for reduced surface drag

- Monitoring of part temperature to avoid heat distortion

All turned parts undergo inspection for roundness, surface quality, and dimensional accuracy.

PEEK CNC Machining FAQs

We machine unfilled (natural), glass-filled (GF30), and carbon fiber–reinforced PEEK. Medical-grade or FDA-compliant materials can also be processed upon request.

For small to mid-size batches or R&D needs, CNC is far more cost-effective than tooling for injection molding — especially when material performance is critical.

We pre-condition and stress-relieve the material before and after machining, and adjust toolpaths to reduce heat and distortion. This ensures better dimensional stability over time.

We’re happy to help. Share your part design and performance goals — we’ll compare PEEK with other high-performance plastics or metals to find the most efficient fit.