What We Offer for Polycarbonate Machining

Polycarbonate offers a rare balance of impact strength, clarity, and thermal resistance — making it a top choice for protective housings, light diffusers, and enclosures. But its benefits also come with machining challenges: poor heat dissipation, surface scratching, and internal stress.

We’ve refined our CNC processes to bring out the best in PC while avoiding common pitfalls — especially for projects requiring both structural precision and a clean appearance.

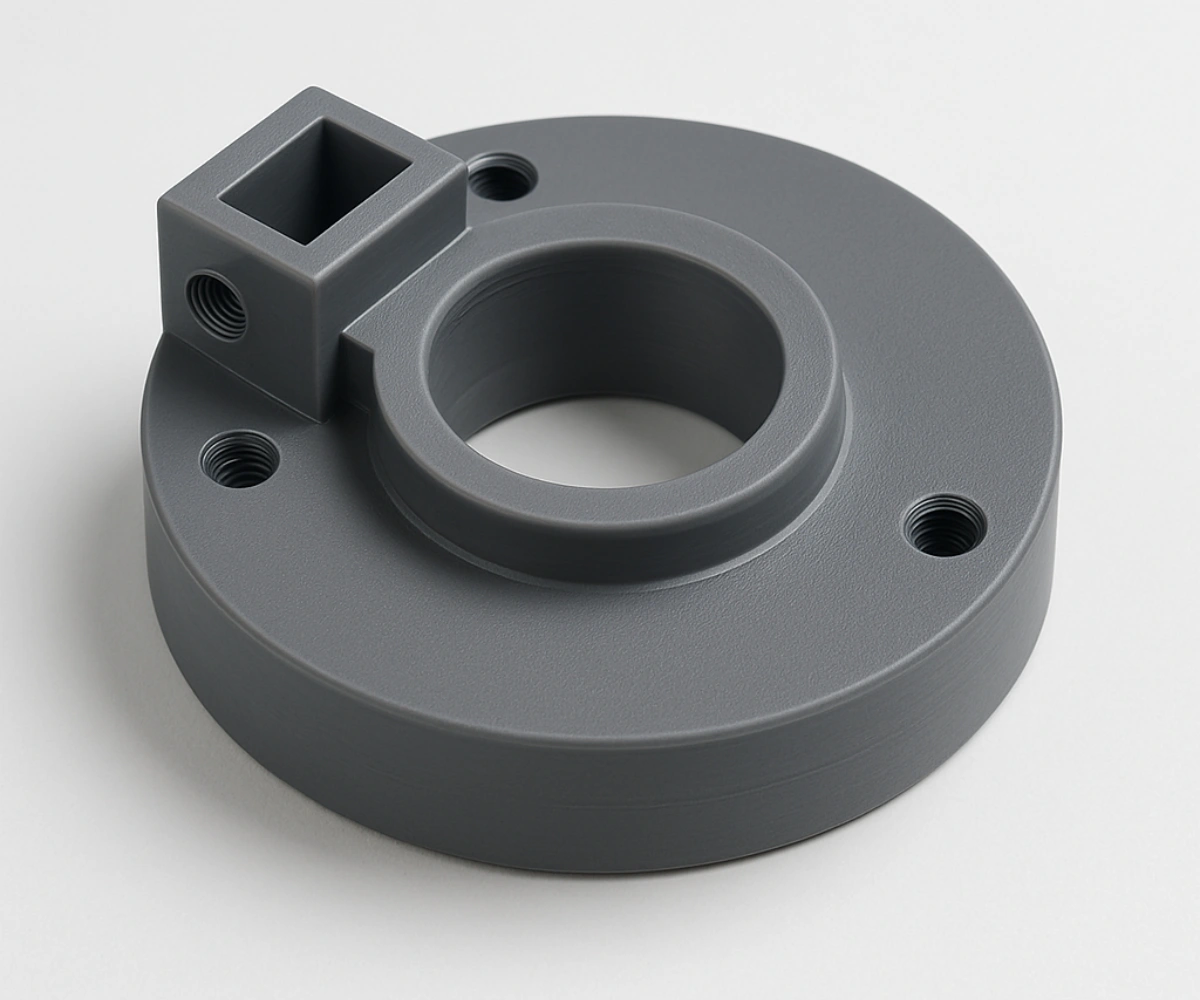

CNC Milling for Polycarbonate

PC is often chosen for components requiring transparency, flat surfaces, or functional fitment. Milling allows us to shape slots, windows, and complex enclosures with high dimensional accuracy.

We use:

- Sharp, polished end mills to reduce surface haze

- Lower feed rates and coolant-free machining to avoid micro-cracks

- Stress-relieving machining paths to minimize warping

This results in smooth surfaces and clear edges — ideal for lighting covers, instrument panels, and precision enclosures.

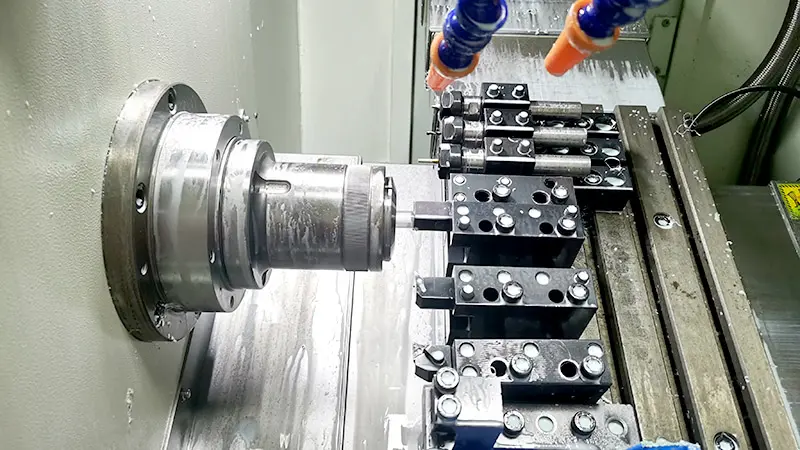

CNC Turning for Polycarbonate

Turning polycarbonate components — such as lenses, bushings, or round caps — requires precise control to prevent cracking, distortion, or swirl marks. The material’s softness can also lead to tearing if tools aren’t properly matched.

We address this with:

- Fine-tuned tool geometries for clean shearing without gouging

- Stable fixturing and light depth of cut to reduce chatter

- Visual QC on each pass to ensure cosmetic quality

Whether your design calls for functional seals or aesthetically clean contours, our turning process ensures parts that meet both technical and visual expectations.

Polycarbonate CNC Machining FAQs

However, if your part requires perfect optical clarity, textured surfaces, or large-scale production, injection molding may be the better fit.

We’ll help you evaluate which process suits your design, quantity, and cost targets — and can support both if your project evolves.

While it won’t match injection-molded lens quality, it’s often suitable for functional prototypes, covers, or light guides.

We commonly hold ±0.05 mm for standard PC geometries. For snap-fit, optical, or thin-walled parts, we adjust our strategy to account for material flexibility and thermal sensitivity.

Yes. We provide deburring, edge smoothing, polishing, and protective film application for clear parts.

Custom textures or coatings can be arranged based on part geometry and volume.