Custom Injection Mold making Services

As an injection mold manufacturer, RJC provides one-stop plastic injection mold making services for all kinds of project needs, from sample verification to mass production. We also offer mold export services that comply with various international standards.

rjc Mold Making Process

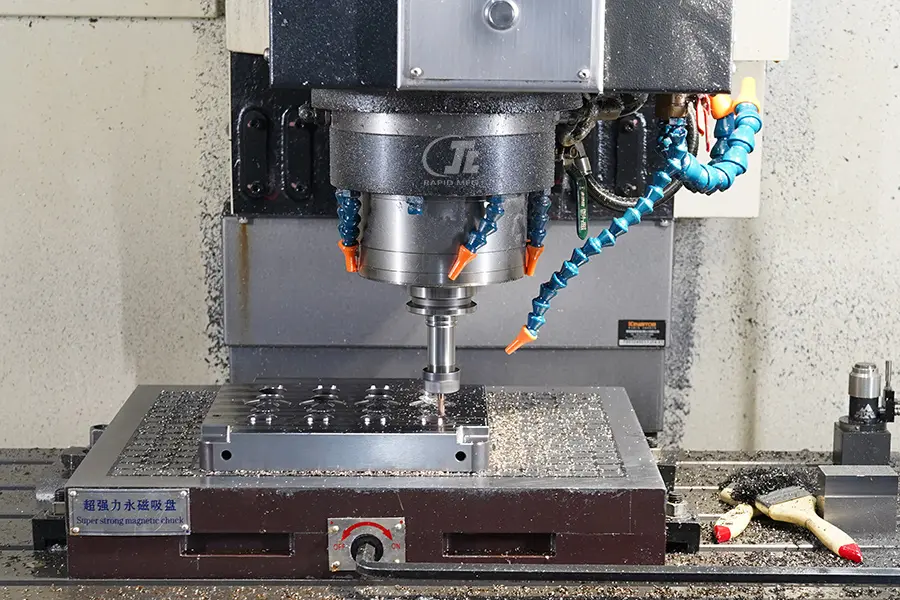

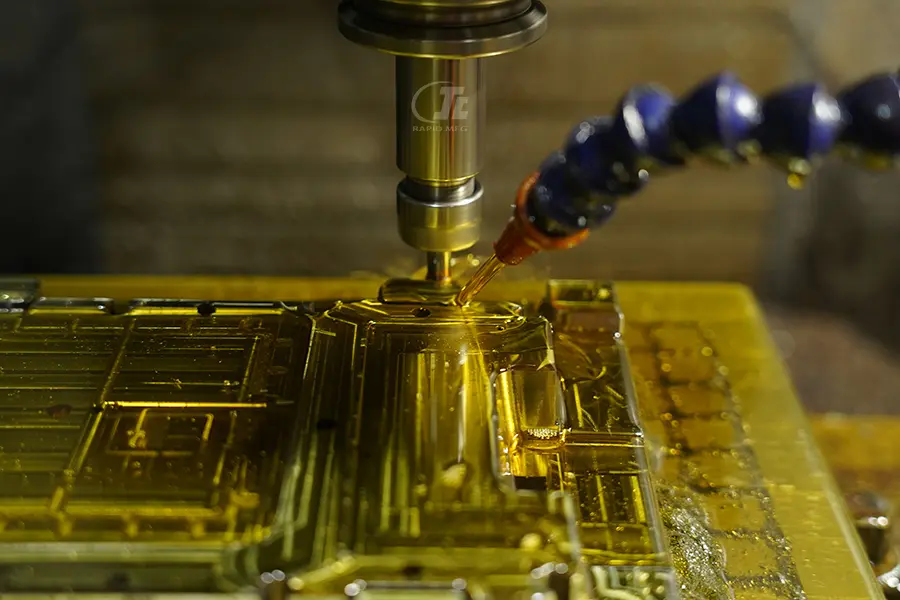

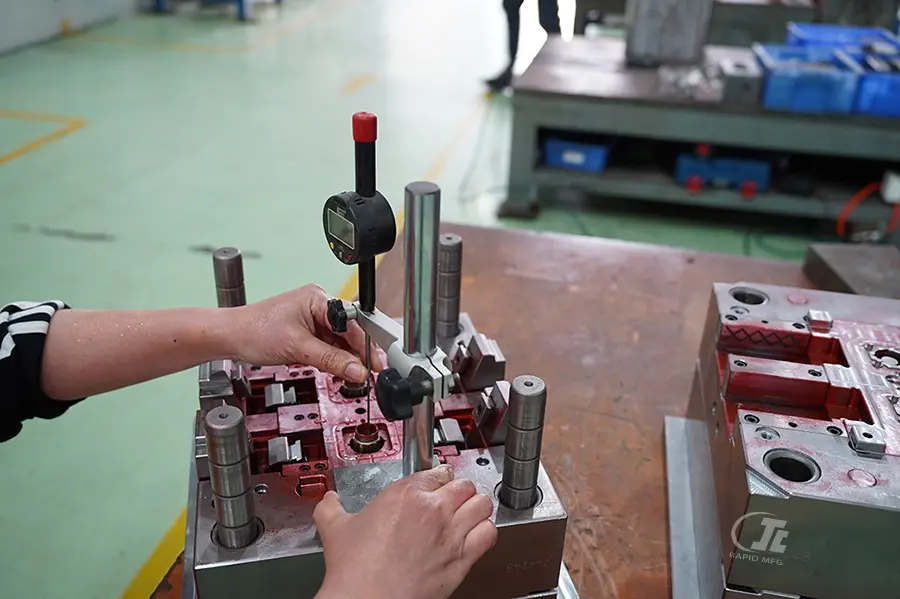

Our mold-making process covers every machining step required to build a production-ready injection mold. The steel blocks are first rough-cut and shaped through high-speed CNC dry machining to achieve the core and cavity geometry. For detailed areas, our team performs CNC oil machining to obtain smooth surfaces and tight tolerances. Wire-cut EDM is then used to create sharp corners, deep slots, and intricate features that cannot be achieved by standard milling. After all components are completed, skilled technicians handle mold fitting, assembly, polishing, and dimensional inspection to ensure perfect alignment and smooth mold function. The final mold is tested and verified before being delivered or used for injection molding.

What types of molds do we offer?

RJC has complete mold design and manufacturing capabilities, as well as injection molding production capabilities.

From a production perspective, we offer rapid molds, high-volume production molds, single- and multi-cavity molds, precision molds, and large-scale molds.

Our mold making capabilities

Standardized Mold Grades to Match Your Production Requirements.

| Mold Class | Purpose | Shot Life | Tolerance | Lead Time |

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | 10-18 days |

| Class 104 | Low-volume Production | Under 100000 cycles | ± 0.02mm | 2-3 weeks |

| Class 103 | Low-volume Production | Under 500000 cycles | ± 0.02mm | 2-3 weeks |

| Class 102 | Medium-volume Production | Under 1000000 cycles | ± 0.02mm | 3-4 weeks |

| Class 101 | High-volume Production | Over 1000000 cycles | ± 0.02mm | 4-5 weeks |

Why work with us

One-stop solution expert ,we are ready to help find your ideal solution

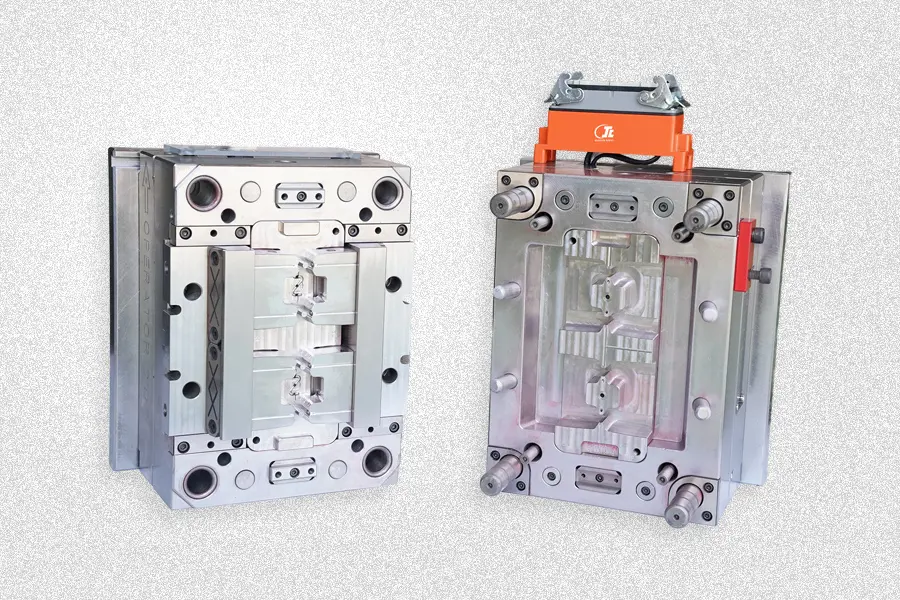

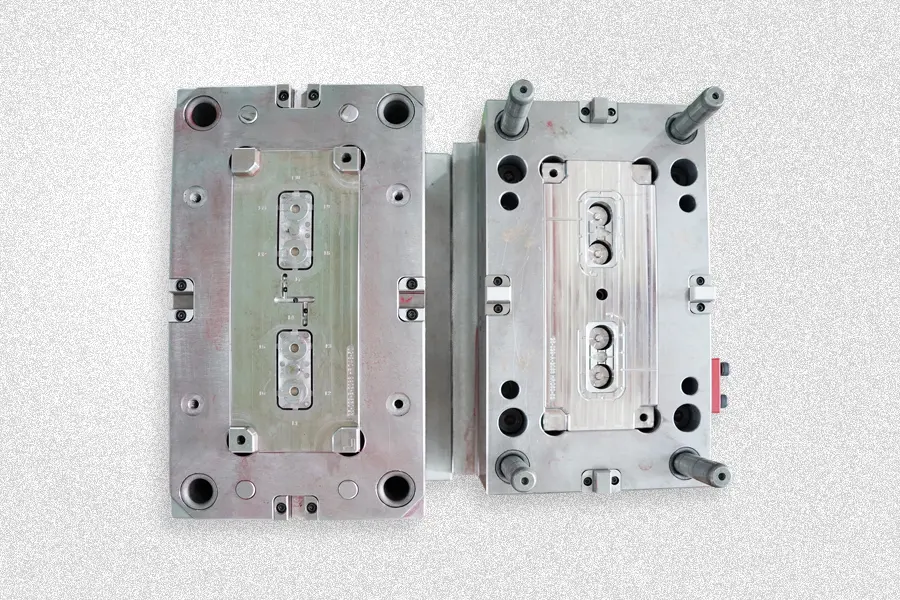

Mold making workshop

From rough machining of molds to assembly, all processes are completed in-house.

Collaboration Process

We provide mold manufacturing services covering the entire product development cycle.

Request Your Free Injection Mold Quote Today

Our Most quotes are delivered within 24 hrs, or faster, depending on project details and your injection molding needs. Your customer support partner will contact you directly to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have about injection molding, the manufacturing process, the materials we use, your quote, and beyond!

FAQS

To provide an accurate quote, we typically require a 3D CAD file (STEP/IGES), 2D drawings with tolerances, material specifications, estimated part volume, and the preferred mold type.

We support both. You can either receive the mold for use at your own facility or leave it with us for long-term molding production.

All of our molds are manufactured in-house, which allows us to fully control the production schedule. We provide weekly progress reports to keep you informed.

For most injection molds, the standard lead time is 3–6 weeks depending on complexity. Expedited services are available for rapid prototyping or urgent production needs.

Yes. We can evaluate and quote based on 2D drawings alone. If 3D models are not available, RJCMold can reconstruct them from 2D drawings for mold flow analysis and mold design, helping you save both time and modeling costs.

Yes. You can choose to have the mold delivered to you or stored at our facility for ongoing production. We offer full injection molding services using the molds we manufacture.

We sign a Non-Disclosure Agreement (NDA) with every customer. Internally, we implement strict project isolation, access control for design files, and a zero-leakage policy to protect your intellectual property.

Plastic injection molds are designed as hollow metal blocks with cavities used to shape molten plastic through the injection process. There are many holes inside the mold, and the temperature can be controlled by means of oil, water or heater.

Gates in the mold allow molten plastic to flow in, which then fills the cavity through runners and gates. After cooling, the mold is opened, and the ejector pin of the injection molding machine is pushed by the top plate to further eject the molded part.

- Guide Pins– Installed to one half of the plastic injection mold and align the two halves by entering the holes in the other half. the most function is to locate the core and cavity insert in right position, avoid steps on parting line of molding parts or mismatch between two halves of molds.

- Runner– Connect the sprue bush to molding cavities, it is a passageway of flow material, the section shape is usually round or trapezoid.

- Gate–The narrowest position of the runner, where the flow material enters the molding cavity. There are many different types, some will be broken from molding part when ejecting out. such as submarine gate, tunnel gate. Some need to be cut after molding. like tab gate, side gate and so on.

- Sprue (Bush) – Tapered hole in the center of the plastic injection mold into which the flow material travel from the nozzle of injection machine to runners

- Locating Ring– Locating the plastic injection mold on the fixed platen of injection machines, so that the injection nozzle lines up with the sprue bush.

- Mould Cavity(include cavity and core)– The space in the mold shaped to produce molding product.

- The ejector (Pins)– Push the runner and molding parts out of the mold

- The Shot– Total amount of material into cavities, include runner and molding parts

- Ejector plate/Ejector backplate: Just for hold the ejectors in the right position

- Clamping plate: Clamping the mold to the platen of injection machines