Home Appliance Components

As a result, RJC is skillful in providing multiple clients with custom household appliance with injection molding, insert molding,multiple-Cavity molding, and so on and has trustworthy customers dedicated to supplying household appliances.

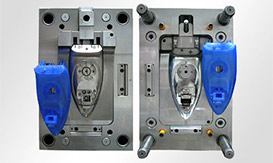

Mold and Products

Home Appliances Housing Mold

Home Appliances Parts Mold

Siemens Low-voltage Switch enclosures

Siemens Mid-Voltage Switch enclosures

Electronic Enclosures

Household Appliance Enclosures

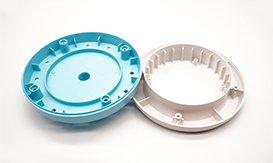

Electric Bowl Enclosures

Switch Enclosures

Value-Added Services

The telecommunications industry is rapidly changing with new technology and devices being rolled out monthly from various companies across the world. To meet the changing demands of electronics, having precision and expertise is most important for your device and its components. Rjcmold Injection molding has the telecommunications injection molding expertise and we can help provide the following for your next product project.

- Design for manufacturing support

- Plastic material development, testing and specification that meet UL, CSA, RoHS and other international specifications

- Engineering and injection mold building

- Custom plastic injection molding

- Plastic part decoration, assembly and packaging

- Collaboration with short run or high-volume contract manufacturers

If we can help you with your project please contact us here.