Prototype injection molding services

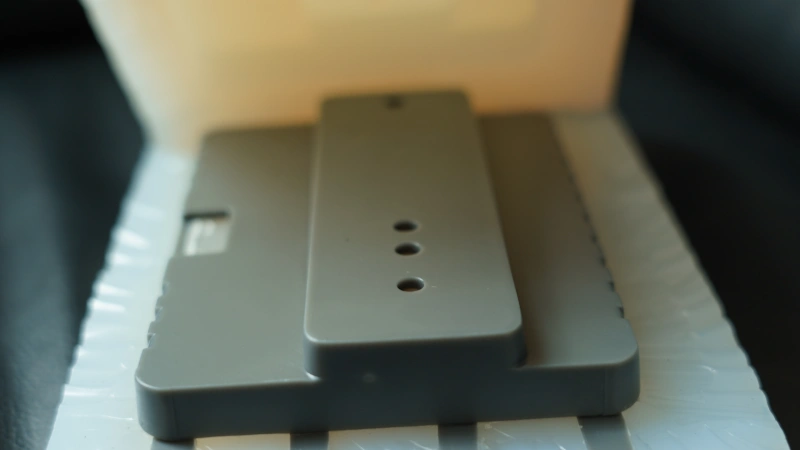

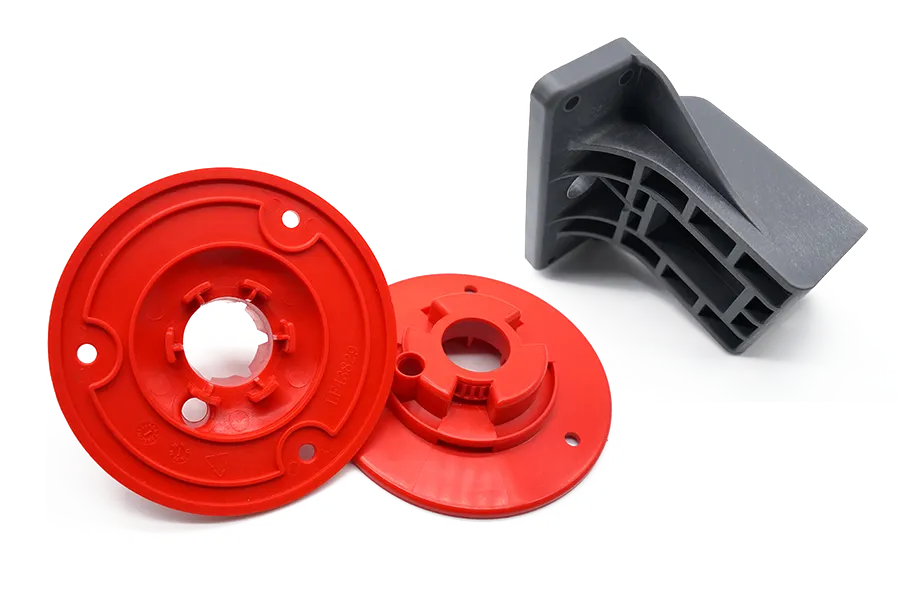

We use low-cost rapid toolings to produce injection-molded prototypes in a short time, providing an economical way to verify product feasibility. Perfect for functional testing of your prototypes.

Our prototyping capabilities

Almost comparable to mass-produced injection molding.

Why Choose Us for Prototype Injection Molding

- Rapid Turnaround – Molds ready in as fast as 7–10 days

- Production-Grade Materials – Same resins as in mass production

- Low-Cost Tooling – Ideal for testing before full-scale investment

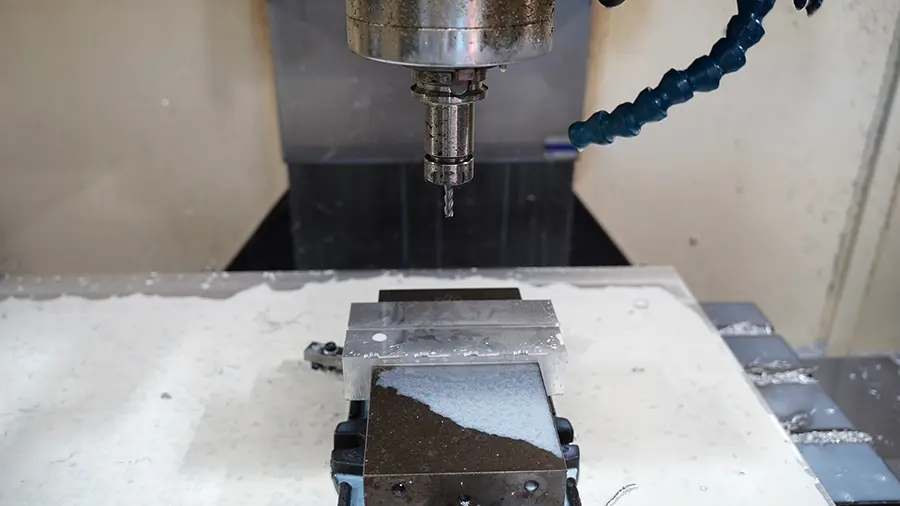

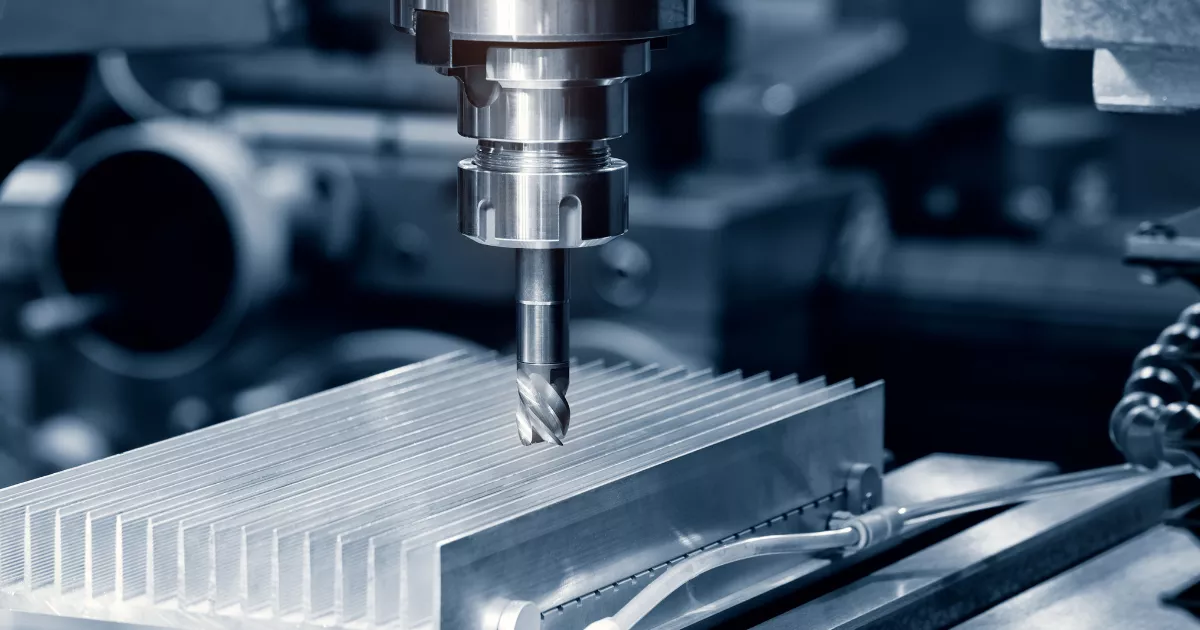

- In-House Manufacturing – CNC machining, EDM, and mold fitting in one place

- Flexible Solutions – Injection molding for >100 pcs, vacuum casting for <100 pcs

- Worldwide Delivery – Fast global shipping

Other alternatives

Note: If your plastic prototype does not require functional testing, we recommend vacuum casting as more cost-effective alternatives.

Not sure which option suits your needs? Contact us today and we’ll provide the best solution.

-

DFM Review – Analyze your CAD files for mold feasibility and recommend the best method.

-

Tooling or Silicone Mold Creation – CNC/EDM for injection molds, or silicone mold for vacuum casting.

-

Production & Delivery – T1 samples or finished parts shipped within days.

FAQS

Rapid prototyping injection molding is a rapid manufacturing process used to produce low volume of plastic parts during the early stages of product development. It helps validate design, functionality, and material performance before full-scale production.

Quantity: Prototypes are typically produced in tens or hundreds, while production runs can reach thousands or millions.

Mold Material: Prototype molds often use aluminum or soft steel, whereas production molds use hardened steel.

Cost & Speed: Prototype molds are faster and cheaper to make but have a shorter lifespan.

The turnaround time is usually 1 to 3 weeks, depending on part complexity and mold design.

Yes, most prototyping molds can accommodate the same thermoplastics used in mass production—such as ABS, PC, PP, and PE—allowing for realistic performance testing.

Related posts

Understand the materials, applications, and processes in the prototype injection molding.