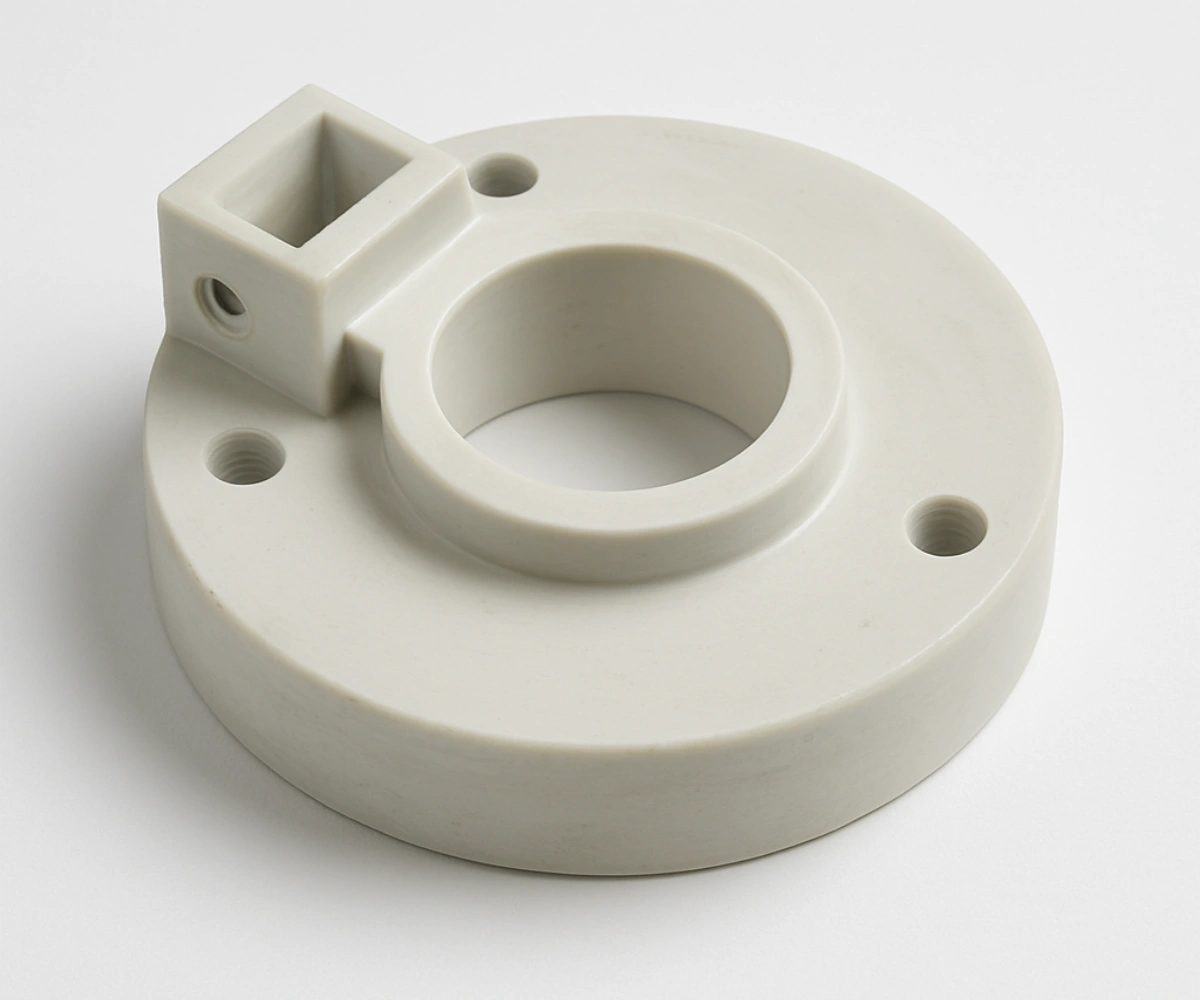

ABS CNC Machining Service

Get custom ABS parts with strong mechanical properties and smooth surface finishes — precision-made and shipped globally.

✔ ISO 9001–certified quality management

✔ From prototyping to full-scale production

✔ Tolerances as tight as ±0.05 mm

✔ Typical lead times of 5 days for most orders

What We Offer for ABS Machining

ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering plastic known for its mechanical strength, good dimensional stability, and excellent machinability. It’s especially popular for electronic enclosures, automotive parts, jigs, fixtures, and general-purpose functional prototypes.

Unlike more brittle plastics, ABS absorbs shock well and resists cracking — making it suitable for both internal structural parts and exterior components. Its ease of machining makes it a reliable choice for fast iterations or early-stage designs.

We tailor our CNC processes to deliver accurate, clean ABS parts while avoiding common issues like edge melting, burr buildup, or internal stress.

CNC Milling for ABS

ABS is highly compatible with CNC milling and is often used for structural plates, mounting brackets, and functional covers. Because it softens under heat, precise toolpath and temperature control is key.

Our milling process includes:

- Sharp tools and moderate feed speeds to avoid surface burns

- Effective chip removal to prevent re-melt or clogging

- Optional surface smoothing and edge finishing

The result is dimensionally accurate ABS parts ready for fit testing, assembly, or end use.

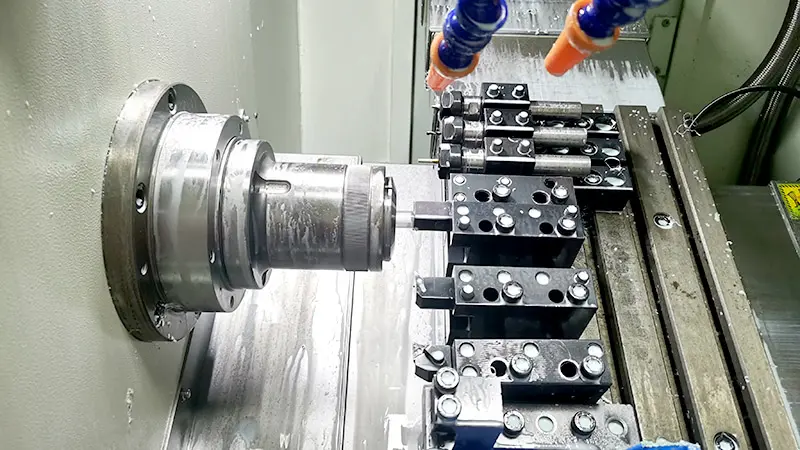

CNC Turning for ABS

CNC turning is ideal for ABS parts with cylindrical shapes, such as bushings, round housings, or mechanical spacers. ABS’s toughness allows smooth turning, but care is needed to prevent tool chatter or melting.

We use:

- Optimized spindle speeds and sharp inserts

- Gentle part holding to prevent deformation

- Secondary deburring for clean finishes

Turned ABS parts are commonly used in functional prototyping, robotics, and consumer product components.

ABS CNC Machining FAQs

Machined ABS parts typically have a matte or semi-gloss surface. We can apply polishing, painting, vapor smoothing, or texturing if cosmetic appearance is important.

We usually achieve ±0.05 mm tolerances for standard ABS parts. For tight-fitting assemblies, we review wall thickness and material behavior to ensure proper fits.

Yes. CNC-machined ABS parts are more dimensionally accurate and mechanically consistent than most 3D printed ABS components, making them a strong option for production-ready prototypes.

It depends on quantity and design maturity. CNC is ideal for prototypes or low-volume production with fast lead times. Once your design is finalized and quantities increase, we can also help you transition to injection molding.