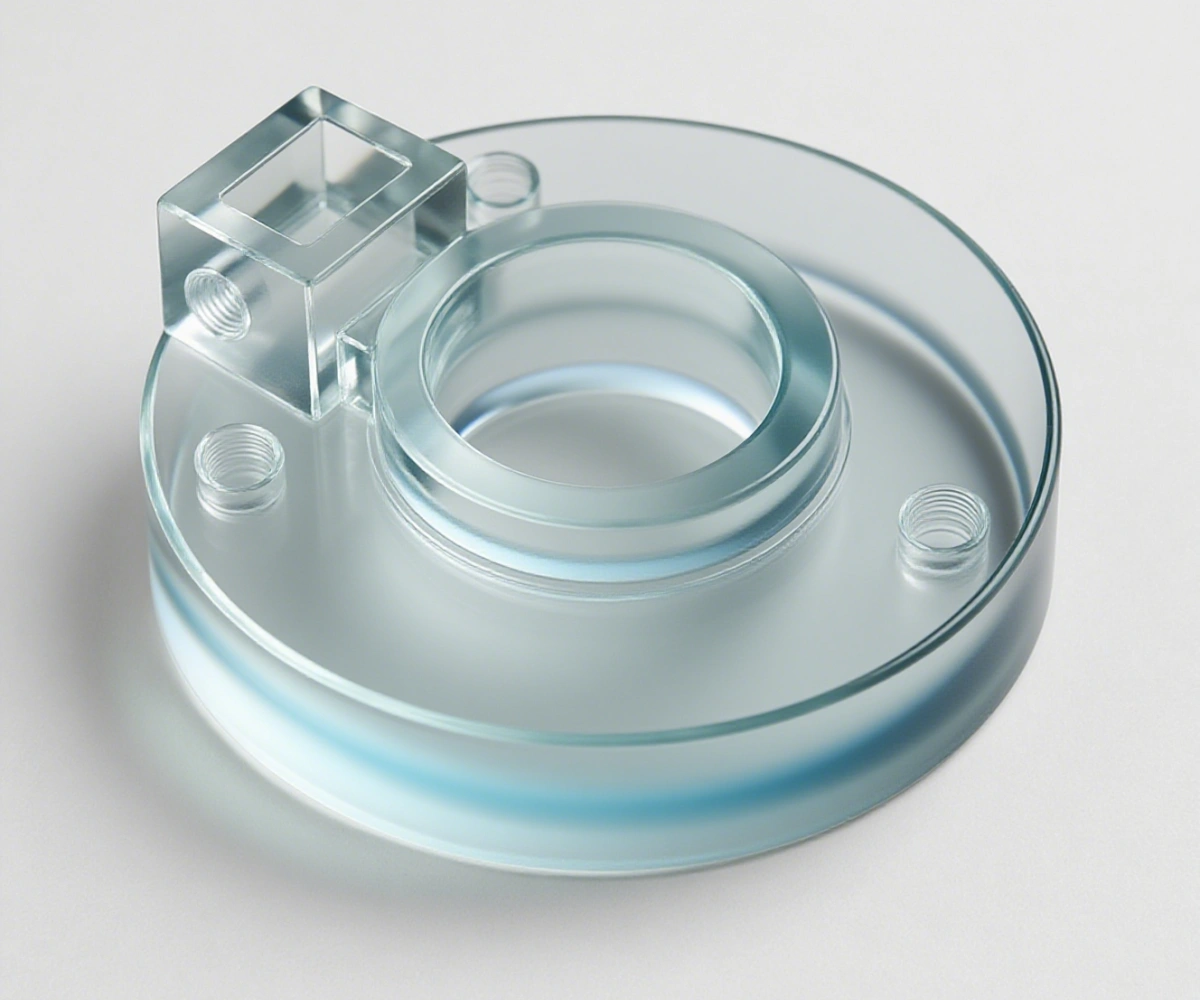

Acrylic CNC Machining Service

Get custom acrylic parts with optical-grade clarity and clean edge finishes — precision-machined and shipped worldwide.

✔ ISO 9001–certified quality management

✔ From prototyping to full-scale production

✔ Tolerances as tight as ±0.05 mm

✔ Typical lead times of 5 days for most orders

What We Offer for Acrylic Machining

Acrylic (PMMA) is a rigid, transparent thermoplastic widely used as a glass alternative. It’s ideal for parts requiring visual clarity, such as display panels, protective windows, light diffusers, and custom enclosures.

However, acrylic is brittle and prone to cracking or edge chipping during machining. Unlike polycarbonate, it has low impact resistance and limited flexibility, so cutting techniques must be carefully controlled to preserve visual and structural integrity.

We’ve optimized our CNC processes to machine acrylic parts with precision, while preserving their clarity and avoiding common defects like crazing, melting, or burrs.

CNC Milling for Acrylic

Acrylic is best suited for flat or contoured parts where transparency, dimensional precision, and surface finish are key. However, incorrect tool selection or high cutting forces can cause clouding, edge chipping, or cracking.

We ensure top-quality results by:

- Using polished, high-helix tools for smooth edges

- Applying low feed rates to prevent heat distortion

- Avoiding coolant contamination that causes optical haze

Optional flame polishing or manual finishing can be added for showcase-ready transparency.

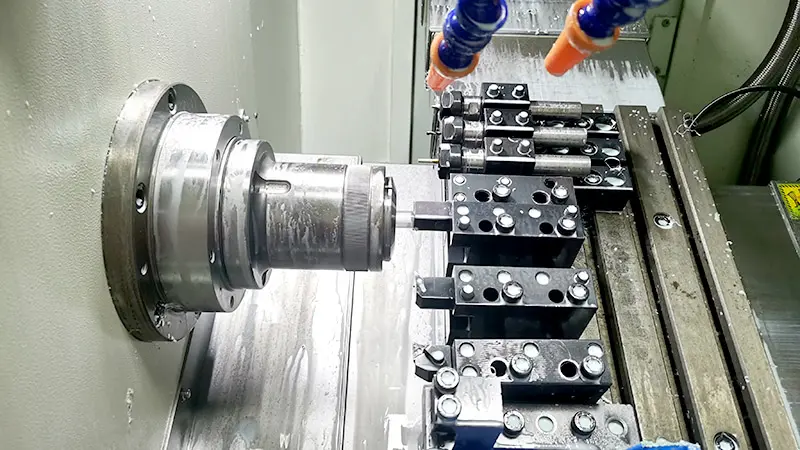

CNC Turning for Acrylic

Acrylic turning is suitable for cylindrical parts like optical lenses, protective domes, or light pipe components. But its brittleness requires slow, controlled tool engagement to avoid stress fractures or surface swirl.

Our turning process includes:

- Ultra-sharp tools with fine tip radii for surface clarity

- Precision fixturing to avoid vibration and cracking

- Polishing options to enhance cosmetic finish

We deliver high-clarity round parts that meet both visual and dimensional expectations.

Acrylic CNC Machining FAQs

Acrylic is brittle — it can crack, chip, or craze under thermal or mechanical stress. We use low cutting forces and stress-minimizing toolpaths to reduce risk and improve consistency.

We typically maintain ±0.05 mm, but for ultra-thin or optical parts we may recommend design adjustments to ensure dimensional and cosmetic reliability.

Yes. We can machine both types, but cast acrylic typically offers better optical quality and lower internal stress — especially for thicker or highly transparent parts.