What We Offer for Nylon Machining

Nylon (PA6, PA66, etc.) is one of the most widely used engineering plastics — known for its excellent strength-to-weight ratio, chemical resistance, and low friction. It’s commonly found in moving components like bushings, gears, insulators, and spacers.

However, nylon is also hygroscopic (absorbs moisture from the air), which can affect dimensional stability over time. To ensure consistent results, we adjust our machining approach to account for these material behaviors.

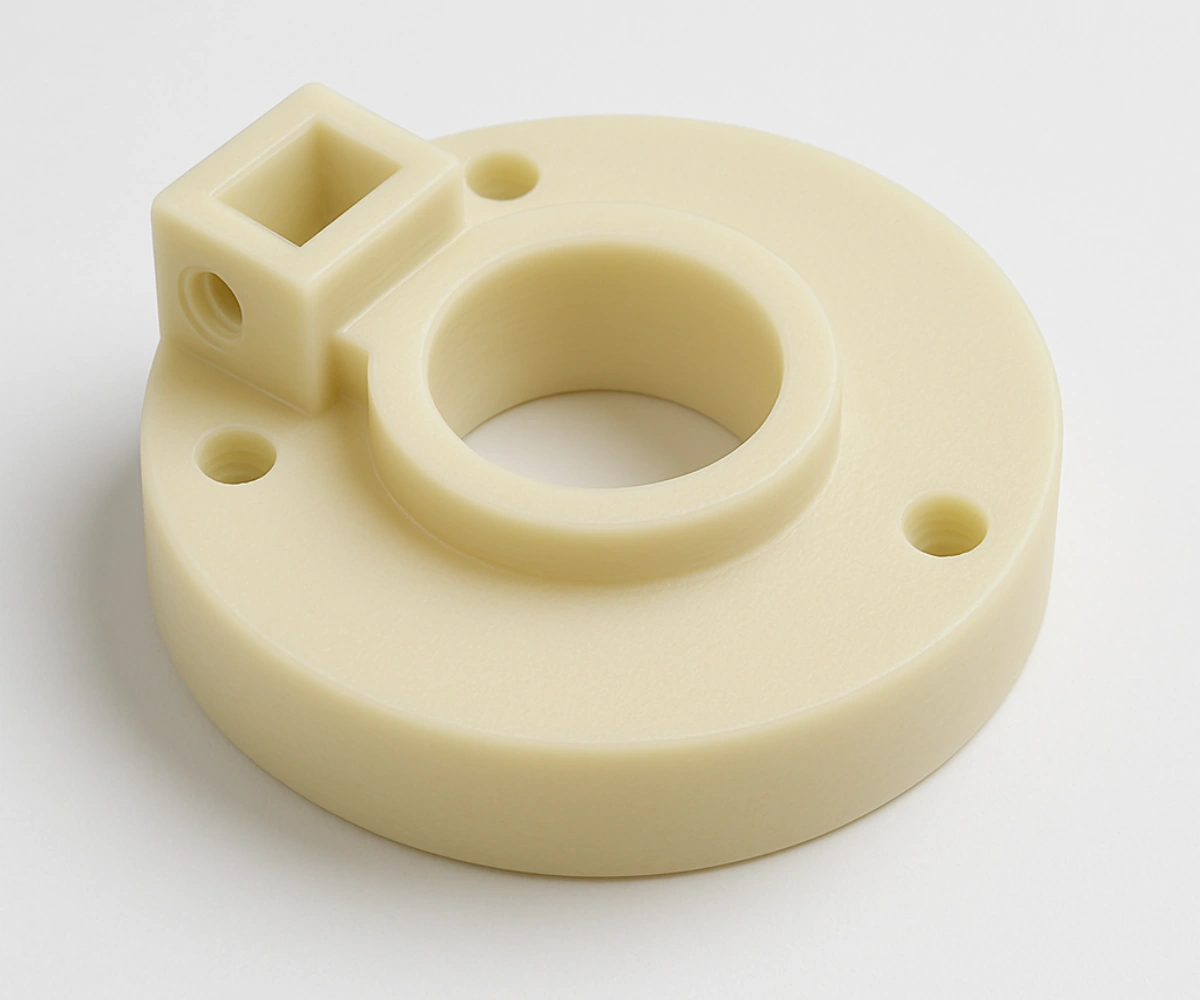

CNC Milling for Nylon

Nylon is well-suited for milled parts that require structural strength and surface functionality — such as housings, guide rails, and support plates. However, its tendency to deform under heat and absorb moisture makes machining accuracy a nuanced task.

We use:

- Sharp, low-friction cutting tools to avoid heat buildup

- Stress-relieving toolpaths for dimensional stability

- Controlled humidity storage before machining

This helps us deliver clean, accurate components with consistent performance in real-world applications.

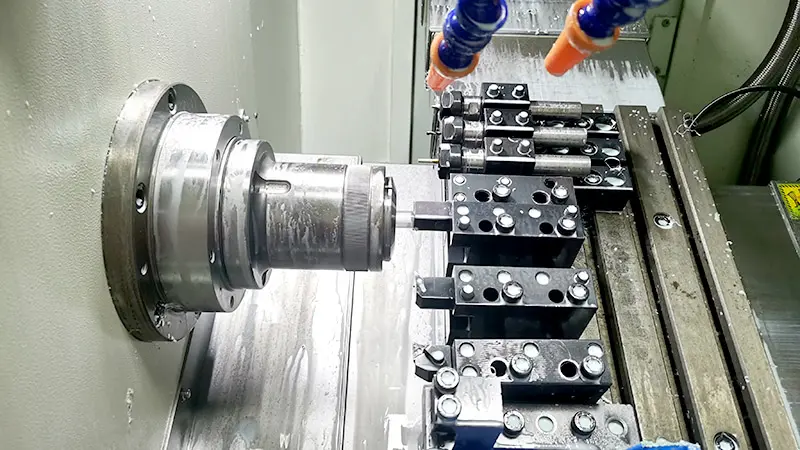

CNC Turning for Nylon

Turning nylon is ideal for creating bushings, rollers, washers, or pulleys — especially where smooth surfaces and low friction are important. But its flexible nature demands precise control to avoid warping or tearing.

Our nylon turning process includes:

- High rake-angle inserts for clean cutting

- Balanced fixturing to reduce chatter

- Monitoring of part temperature to avoid deformation

The result: durable, well-finished round parts that hold up under dynamic loads and long-term wear.

Nylon CNC Machining FAQs

We store nylon in humidity-controlled conditions and adjust machining parameters based on pre-conditioning. While some dimensional change is inherent to nylon, we can advise on tolerances and design compensation if needed.

We usually hold ±0.05 mm on standard nylon geometries. For load-bearing or fit-critical components, we apply special machining strategies to improve repeatability and dimensional control.

Absolutely. Share your design and application — we’ll help you assess whether nylon is the right material and process for your performance needs.