Teflon CNC Machining Service

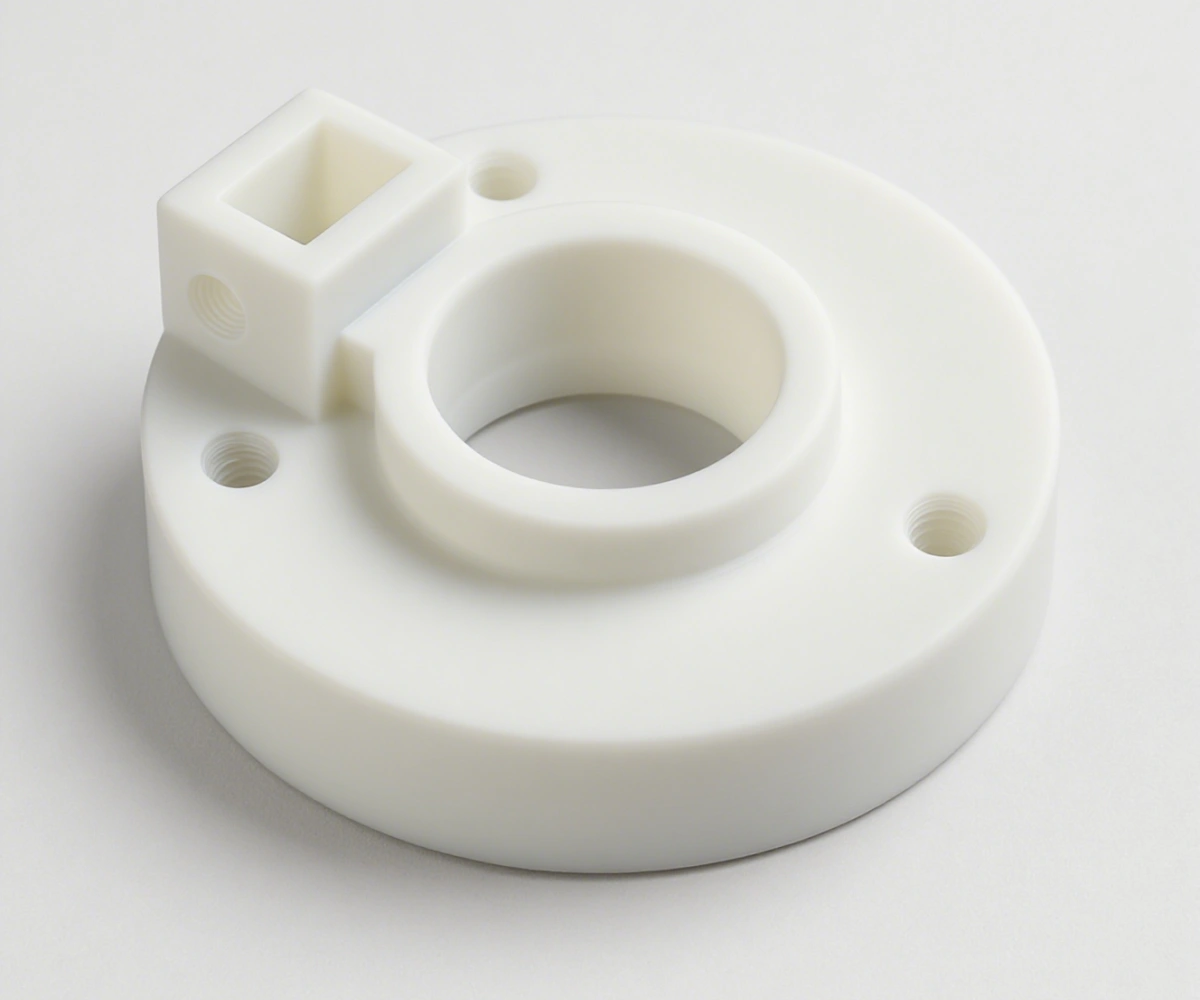

Get custom PTFE (Teflon®) parts with excellent chemical resistance and ultra-low friction — precision CNC-machined in China and shipped worldwide.

✔ ISO 9001–certified quality management

✔ From prototyping to full-scale production

✔ Tolerances as tight as ±0.05 mm

✔ Typical lead times of 5 days for most orders

What We Offer for Teflon Machining

Teflon (PTFE) is prized for its non-stick properties, thermal resistance, and near-universal chemical inertness, making it ideal for demanding applications in chemical processing, medical, and electronics.

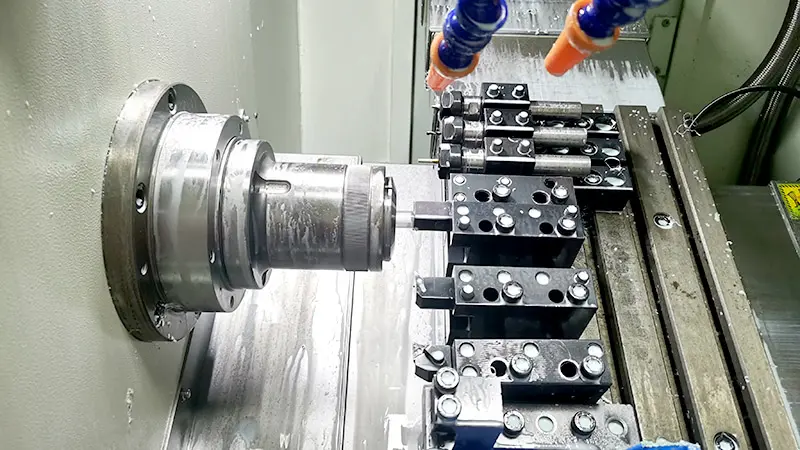

However, its softness, creep behavior, and low rigidity can pose machining challenges — including burrs, deflection, and difficulty holding tolerances. We’ve refined our process to manage these issues through controlled cutting and optimized fixturing.

Teflon CNC Machining FAQs

We support standard virgin PTFE as well as glass-filled or carbon-filled grades depending on application needs. Let us know your specific requirements when quoting.

We typically achieve ±0.05 mm, but for thin-walled or flexible parts, we’ll assess on a case-by-case basis and suggest design adjustments if needed.

Most PTFE parts have a matte-white surface after machining. We offer optional edge deburring or polishing, but due to its low surface energy, PTFE is not suitable for coatings or paints.

Teflon offers excellent chemical and electrical performance but isn’t dimensionally rigid like engineering plastics. If your application involves mechanical stress, we’ll help evaluate alternatives like PEEK or PPS.