Our Nylon Injection Molding Capabilities

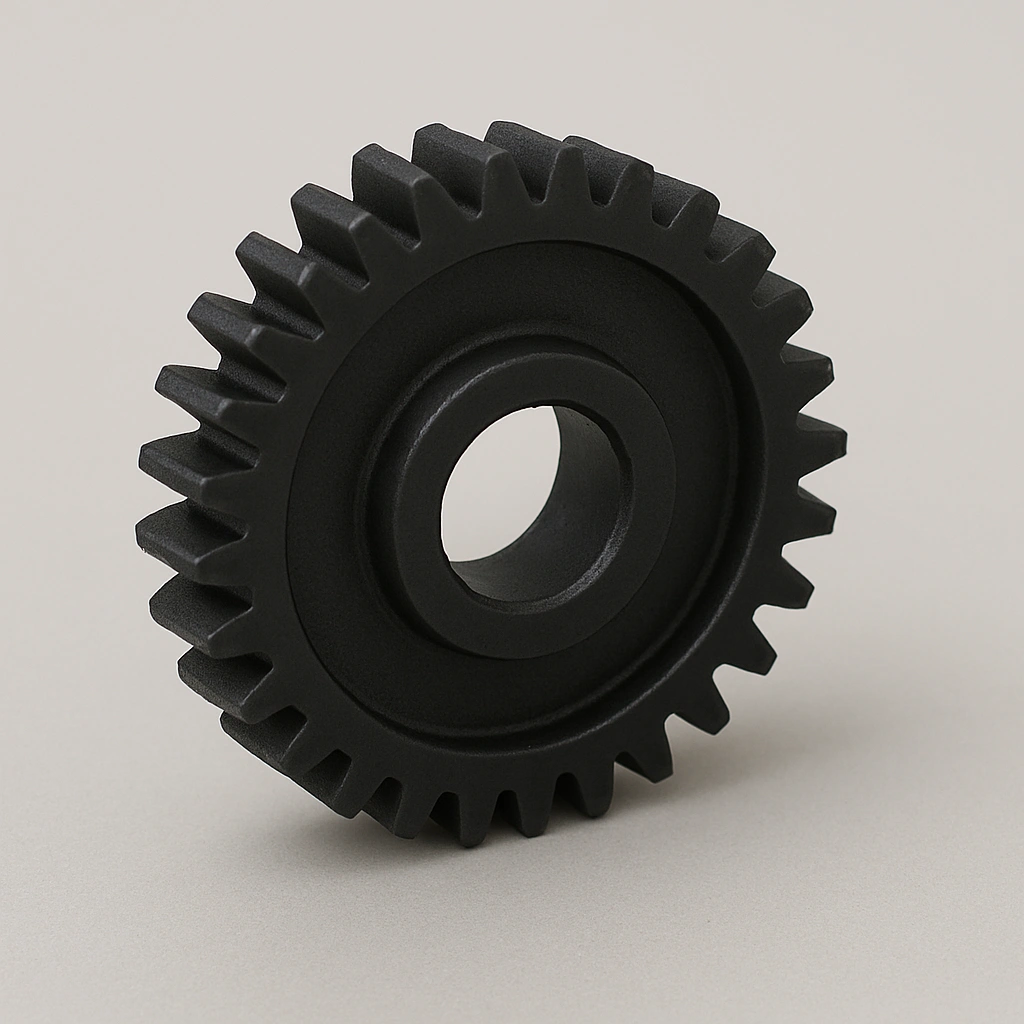

From durable gears to lightweight automotive components, we deliver nylon molding solutions tailored to your industry’s performance needs.

Product Design Support

- DFM analysis for load-bearing and wear-resistant parts

- Guidance on shrinkage and dimensional control for PA6, PA66, and reinforced grades

- Material selection including glass-fiber reinforced and heat-stabilized nylons

Mold Design & Manufacturing

-

Precision venting and gating to reduce voids and sink marks

-

Cooling optimization to control crystallinity and part strength

-

Surface texturing for grip enhancement or aesthetic purposes

Plastic Injection Molding

- Tight tolerance molding for functional assemblies (±0.03 mm)

- Controlled moisture content for consistent molding performance

- Capability to mold unfilled, glass-filled, or impact-modified PA grades

Post-processing & Assembly

- Machining for fine tolerance adjustments

- Painting, coating, or overmolding with rubber for comfort grips

- Pre-assembly and custom packaging services

What is Nylon – Polyamide (PA)

Nylon, or polyamide (PA), is a versatile engineering thermoplastic known for its high strength, toughness, and wear resistance. It exhibits good chemical resistance and self-lubricating properties, making it suitable for gears, bearings, fasteners, automotive components, and industrial machinery. Nylon absorbs moisture from the environment, which affects its dimensional stability and mechanical properties. Proper drying before injection molding or CNC machining is essential to maintain precision and surface quality.

| Property | Typical Value / Description | Notes |

|---|---|---|

| Tensile Strength | 70–90 MPa | High strength, suitable for load-bearing components |

| Flexural Strength | 100–120 MPa | Provides rigidity and structural stability |

| Impact Strength (Notched/Unnotched) | 60–100 J/m | Good toughness, resists wear and sudden loads |

| Elastic Modulus | 2.5–3.0 GPa | Balances stiffness and flexibility |

| Heat Deflection Temperature | 90–180°C | Varies by Nylon grade; crystalline grades are more heat resistant |

| Density | 1.13 g/cm³ | Moderate density, lightweight for engineering parts |

| Chemical Resistance | Good; resists oils, fuels, and mild acids/bases | Sensitive to strong acids, bases, and oxidizing agents |

| Water Absorption | 1–3% | Moisture affects dimensional stability and mechanical properties; drying required before processing |

| Shrinkage | 0.5–1.5% | Mold design must account for shrinkage, especially in thick sections |

| Flammability | UL94 V-2 | Moderate flame resistance; can be improved with additives |

Common Applications of Nylon Molded Parts

| Industry | Example Parts | Why PA Works Well |

|---|---|---|

| Automotive | Engine covers, intake manifolds, brackets | High temperature stability, mechanical strength |

| Industrial | Gears, bushings, rollers | Wear resistance, self-lubricating properties |

| Consumer Goods | Tool handles, sports equipment | Lightweight, impact resistance |

| Electrical | Cable ties, connector housings | Insulation properties, dimensional stability |

Production & Delivery Solutions

| Solution Type | Best For | Typical Lead Time | Notes |

|---|---|---|---|

| Rapid Prototyping | Functional testing & design validation | 7–12 days | Ideal for wear and load testing |

| Small Batch | Pre-production and pilot runs | 2–3 weeks | Cost-efficient for low-volume applications |

| Mass Production | High-demand, consistent quality runs | 3–5 weeks | Optimized for mechanical performance |

| Export Molds | Overseas PA molding production | 4–6 weeks | Built to international durability standards |

Nylon Injection Molding FAQs

Yes, PA absorbs moisture from the environment, which can affect dimensions and properties. Moisture conditioning may be applied to stabilize parts.

Unfilled PA typically operates up to 100–120°C; heat-stabilized and glass-filled grades can go higher.

Certain PA grades are FDA-compliant; certification is available upon request.

Standard PA may degrade under UV exposure; UV-stabilized grades are recommended for long-term outdoor use.