Our PEEK Injection Molding Capabilities

From concept to delivery, our experienced team ensures your high-performance PEEK parts meet exact specifications with quality and speed.

Product Design Support

- DFM analysis focusing on high-temp polymer processing

- Material grade selection tailored to application requirements

- Structural optimization to minimize stress and warpage

Mold Design & Manufacturing

- Precision steel molds designed for high-temp cycles

- Specialized cooling and gating systems for PEEK’s melt behavior

- Domestic and export mold manufacturing options

Plastic Injection Molding

- Strict tolerance control (±0.02 mm achievable)

- Machine tonnage: 50T – 1000T to handle complex geometries

- Single-shot and multi-shot molding for complex assemblies

Post-processing & Assembly

- Machining, surface finishing, plating

- Ultrasonic welding and cleanroom assembly

- Custom packaging and labeling for medical/industrial compliance

What is PEEK – Polyether Ether Ketone

Polyether Ether Ketone (PEEK) is a high-performance engineering thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. It can operate continuously at high temperatures up to 250°C and withstand harsh chemical environments. PEEK is widely used in aerospace, automotive, medical devices, and high-performance industrial components. It can be processed through injection molding or CNC machining, though both require precise temperature control and careful handling due to the material’s high melting point and hardness.

| Property | Typical Value / Description | Notes |

|---|---|---|

| Tensile Strength | 90–100 MPa | Very high strength, suitable for load-bearing components |

| Flexural Strength | 150–180 MPa | Excellent rigidity for structural parts |

| Impact Strength (Notched) | 50–70 J/m | Moderate toughness; generally rigid and durable |

| Elastic Modulus | 3.5–4.0 GPa | High stiffness |

| Heat Deflection Temperature | 250–260°C | Can withstand continuous high-temperature operation |

| Density | 1.30 g/cm³ | Relatively heavy among engineering plastics |

| Chemical Resistance | Excellent; resistant to acids, bases, and organic solvents | Suitable for harsh chemical and high-temperature environments |

| Water Absorption | <0.5% | Very low, maintaining dimensional stability |

| Shrinkage | 0.3–0.5% | Low; mold design must still consider shrinkage for tight tolerance parts |

| Flammability | UL94 V-0 | High flame resistance |

Common Applications of PEEK Molded Parts

| Industry | Example Parts | Why PEEK Works Well |

|---|---|---|

| Aerospace | Structural components, insulation | High strength-to-weight ratio, heat resistance |

| Medical | Surgical instruments, implant parts | Biocompatibility, sterilization resistance |

| Automotive | High-temp under-the-hood parts | Chemical resistance, thermal stability |

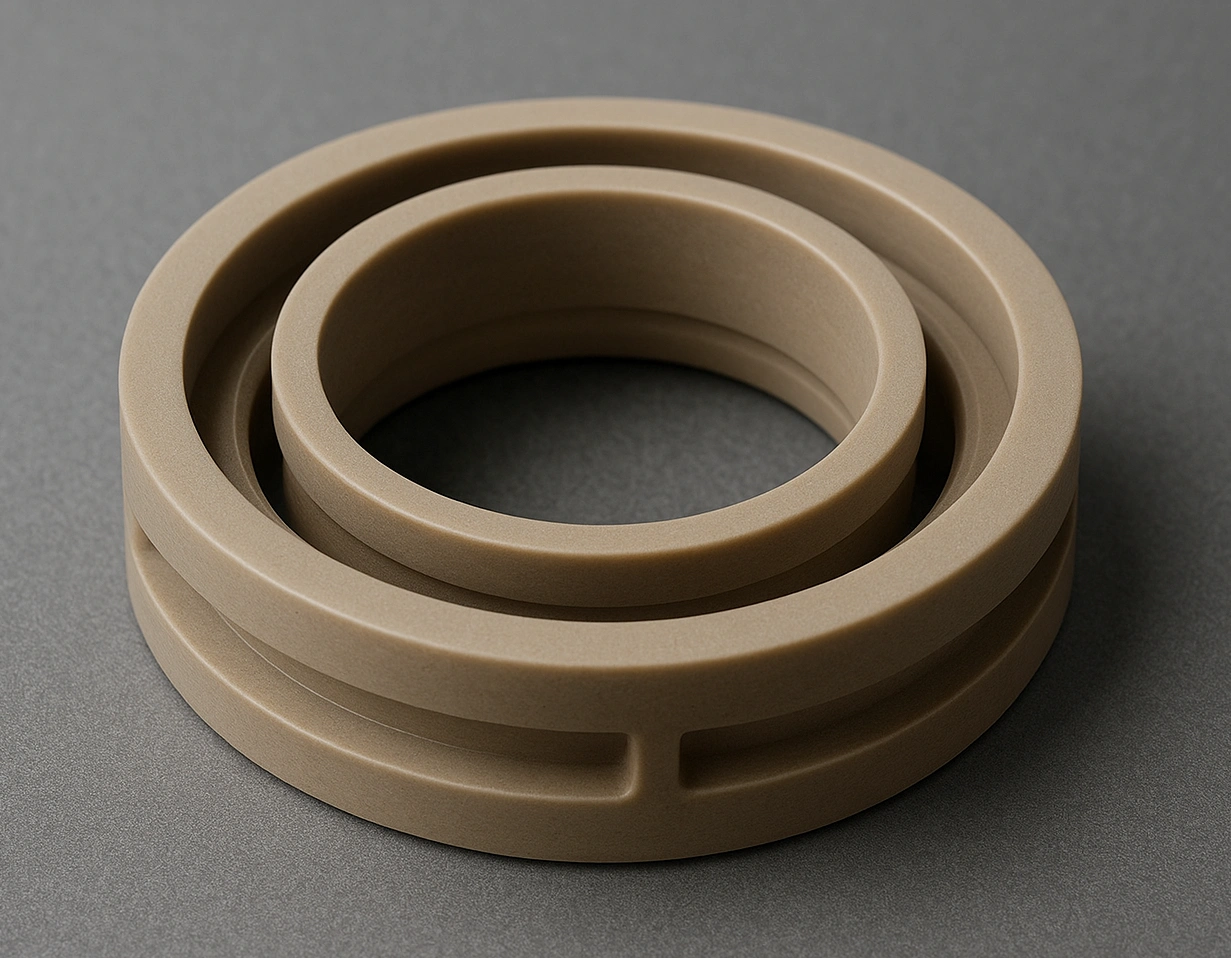

| Industrial | Pump components, seals, valve parts | Wear resistance, dimensional stability |

Production & Delivery Solutions

| Solution Type | Best For | Typical Lead Time | Notes |

|---|---|---|---|

| Rapid Prototyping | Early design validation | 3–7 days | Fast, cost-effective |

| Small Batch | Low-volume production | 1–2 weeks | Flexible order size |

| Mass Production | Large-scale manufacturing | 2–5 weeks | Optimized for cost per part |

| Export Molds | Overseas in-house molding | 4–6 weeks | EU/US standard compliance |

PEEK Injection Molding FAQs

Prototype runs typically take 5–10 days, production orders 3–6 weeks depending on complexity and quantity.

We support from single-piece prototypes up to high-volume production without MOQ constraints.

Yes, we offer various grades including reinforced and virgin PEEK tailored for mechanical, chemical, or medical needs.

Absolutely, all export molds meet EU, US, and medical device manufacturing standards.