In Mold Decorating (IMD)

At Rjcmold, we offer high-quality in-mold decorations, expertise and solutions. Our design tools and experience allow us to be a resource to validate an In Mold Decoration project, prototype and scale production parts even at a large scale. Interested in integrating IMD into your next project? Call us today.

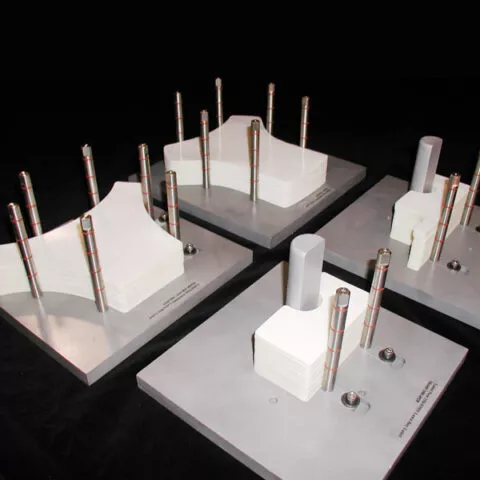

Our custom IMD manufacturing capabilities

We can customize IMD parts to meet your exact specifications and create the unique user experience that will take your products to the next level. We offer a wide variety of finishes, colors and other graphics characteristics to align with your brand identity and application requirements. We use our industry-leading technology and durable graphics expertise to help you achieve your goals and create parts that will elevate your products above the competition.

Much of the success of any in-mold decorating project is the early development of the chosen suppliers and the concurrent development of all materials and processes. Remember to allow enough time to achieve your goals and contact us early in the process.

What is in-mold decorating?

In-mold decoration is a process developed to provide product designers and original equipment manufacturers (OEMs) with an alternative method for decorating their plastic products. The process involves placing a decorated thin film plastic (applique), formed to fit the shape of a mold which is placed into an injection mold injecting plastic either behind or on top of the film. When the mold opens the part is decorated and the graphics are embedded in the part.

This type of decorating exists in contrast to earlier methods of decorating plastic parts. Those methods used spray painting, labeling, screen printing, laser etching, or other methods of modifying the first surface of plastic parts. Exposed to the elements, those older surface decoration methods tended to wear out over time.

IMD has evolved to provide exceptional colors, and graphics along with distinct finishes (such as metalized appearances) and different levels of surface gloss and textures.

The durability of the product is exceptional as the graphics are applied to the back side of the applique, which is sandwiched between the applique and molded resin. Applique materials can be made using “hard-coated plastic films” that in many instances have higher chemical and abrasion resistance than the molded resins used to make the part.

These qualities are particularly useful in medical and other industries where the product is cleaned many times during its lifetime. The added abrasion resistance of these applique films provides for a long lasting display window where LCD or other electronic displays need to be read through for the life of the product.

Advantages of in-mold decoration

Experience new design possibilities with in-mold decoration and eliminate the tedious post-moulding labour. Streamline your production to reduce your costs.

And there are other advantages of this innovative technology, too:

- Extremely versatile uses

- Creates a completely sealed surface

- Works with a wide range of materials

- No need for secondary finishes

- Wide range of finishes can be included, including UV-stable or anti-bac

- Possibility to incorporate living switches

- No need for post-moulding labelling

- Work with spot colour or full graphics

- Can reduce the cost of moulding materials

In-mold decoration is, without a doubt, an extremely advantageous process. Many precision parts simply cannot be created any other way.

Common Application Examples

The massive benefits in-molding decoration presents have made it the preferred choice for a wide range of industries for diverse applications.

Below are some of the industries that make use of in-mold decorations:

- Medical devices

- Display windows

- Personal telecommunication devices

- Large parts and components

- Lawn and garden equipment

- Consumer products

- Consumer handheld devices

- Plastic housings

- Instrument panel

- Automotive components

- Computer components

Why choose Rjcmold Industries

Manufacturers choose Rjcmold for custom in-mold decorating solutions because we have the knowledge, experience and technical skill to create outstanding products with every production run. We live and breathe custom graphics solutions and use our passion to enhance our customers’ products and operations. Our materials science expertise and global reach provide exceptional value and help accelerate the product development process.

Ultimately, manufacturers choose Rjcmold because they trust us to provide great products, a great experience and to deliver projects with unbeatable customer service.