Thin-wall Injection Molding and mold Manufacturer & Supplier

Thin wall injection molding is increasing in popularity as material costs continue to rise and delivery lead times are squeezed. Thin wall molding offers the opportunity to reduce material part cost and to increase production output through faster cycle times.We have the thin wall injection molding expertise to produce complex parts with continuous wall sections as thin as 0.010” (0.25mm). Our part design and engineering skills enable us to optimize parts for superior strength without altering your parts’ critical dimensions.

Due to the fast running speed of this thin-walled injection mold, and the cycle time can sometimes reach 4s, high-quality mold design and mold construction are the key factors for the success of thin-walled molding. Rjcmold’s strong engineering skills and professional experience base will help ensure excellent mold design for thin-wall forming. In addition, it is an effective measure to train process technicians and management personnel in the precision science of thin-wall forming.

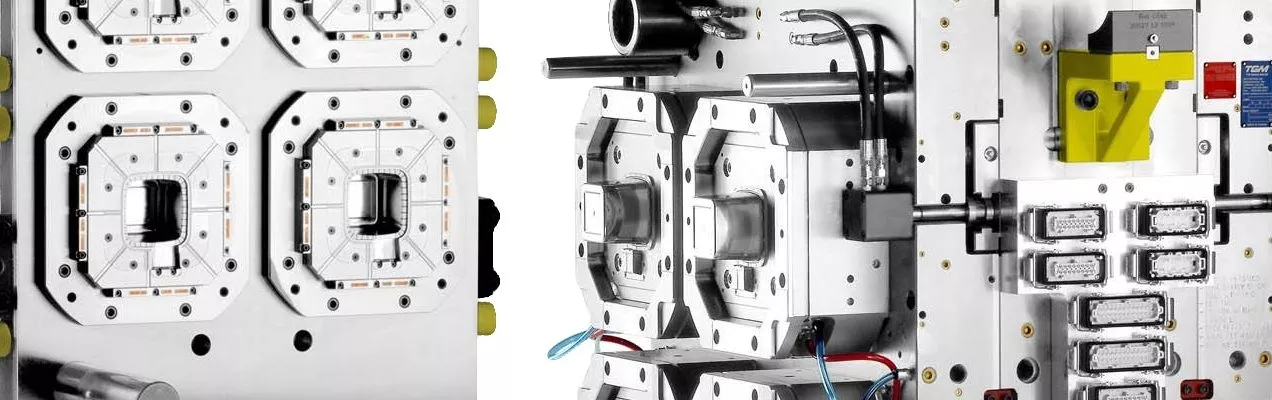

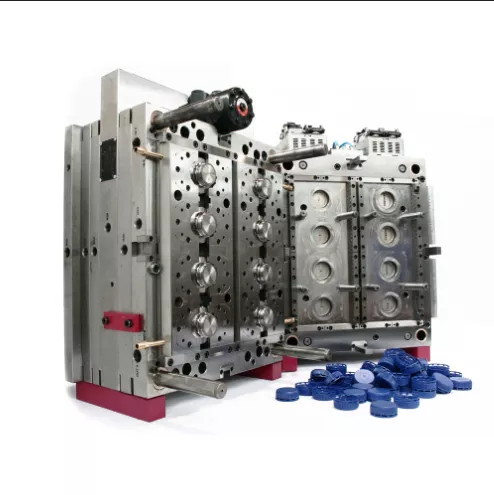

Thin wall plastic injection molds

Demands to create smaller, thinner odd-shaped parts have made the ability to design and build thin wall mold a well sought after commodity.Thin wall plastic injection molds are specialized molds that focus on mass-producing plastic parts that are thin and light.The thin wall parts provide product weight reduction, material cost savings, and faster cycle times, which means higher productivity and lower costs per part. A consistent and repeatable thin wall finished product is critical to performance and requires tight tolerances in the mold design as well as expertise in knowledge of plastics and shrinkage.

With over 20+ years of mold building experience, Rjcmold has not only progressed with the technological demands, but has met new demands head on.

From single cavity prototypes to multi-cavity stack molds, from round to square, from hot runners to some of our patented ejection technologies, Rjcmold has you covered.

Our tools are built with the highest technology and with great consideration to balanced cooling, ease of maintenance and longevity. This enables us to achieve shorter cycles, less downtime and consistent part quality. This gives our customers the best possible end product, reduced costs and higher productivity.

We take pride in all the thin wall molds we manufacture. Through research and development, we continue to invest in technological improvements. Yichuan’s dedicated R&D group will continue to bring our customers new product solutions and better mold technologies.

Thin Wall Molding

Thin wall molding is a specialized form of conventional injection molding that focuses on mass-producing plastic parts that are thin and light, without structural compromise, in order to achieve material cost savings and shorter cycle times. Faster cycle times improve productivity and lead to lower costs per part.

With 55,000 square feet of manufacturing space, 45 molding presses, and three shifts providing 24/7 production, Rjcmold is fully equipped to produce custom injection moldings to match your specifications. We have some of the largest high speed, fully electric, servo controlled molding presses available for contract manufacturing in the western US with tonnages up to 1,250 and shot sizes up to 16 lbs.

Our processes are tailored to meet each client’s specific requirements and encompass all aspects of injection molding customization, from effects and colors to gauging, inspections, secondary assembly, kitting, final packaging, and inventorying of finished goods.

From start to finish, we fully support your project’s needs, whether that means producing hundreds of parts or millions. We provide a full range of complex plastic injection molding capabilities to meet your unique requirements.

Advantages of Thin Wall Injection Molding

We will expand your manufacturing capabilities through the use of the latest thin wall molding technology and injection molding industry expertise. Our experience in the design, creation, and implementation of thin wall injection molds will enable you to produce higher quality thin wall products more cost-effectively and efficiently.

Applications

Thin wall plastic injection molding is used in a wide range of applications including:

- Plastic packaging

- Food packaging

- Plastic housings

- Medical devices

- Medical disposables and medical device packaging

- Consumer products and consumer product

- plastic packaging

- Plastic containers and lids

- Electronic housings and protection

- Cell phone and handheld device components

Are You Looking For Thin-wall Injection Molding Service?

Rjcmold has been molding thin wall and extreme thin wall parts for over 20 years. We mold parts everyday that people said could not be molded. Whether the part is PEEK, exotic filled compound, or high glass / carbon fiber filled we have molded it in thin wall applications.

Contact us for design assistance, free quote, and expert advice today.Your inquiry will be replied within 12 working hours, and we respect your privacy.