Two Shot Mold Manufacturer

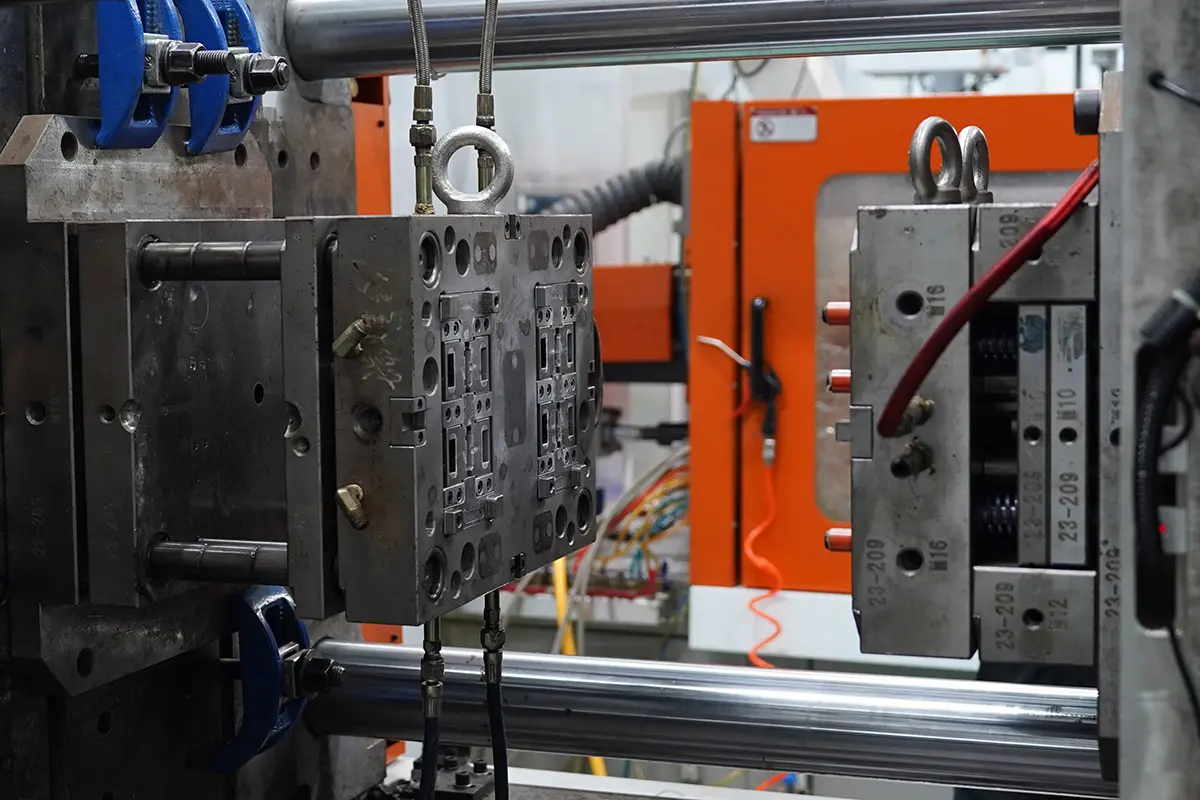

Rjcmold has been around for close to 20+ years, amassing valuable experience through those years that puts us in the correct position to handle all your mold needs. We have a team of qualified experts who are well versed with all the two-shot injection molding techniques. You are assured of getting exactly what you need.

Your B2B needs are also well covered by our services. We offer good discounts on bulk purchases for our most loyal clients to help them hit the road running. Continued support is the core of our business.

Two shot injection mold solutions

With the 2K technique a possible assembly step is prevented.

The choice for a 2K or 2-component injection molding process is primarily based on a cost advantages, design features or aesthetic preferences.

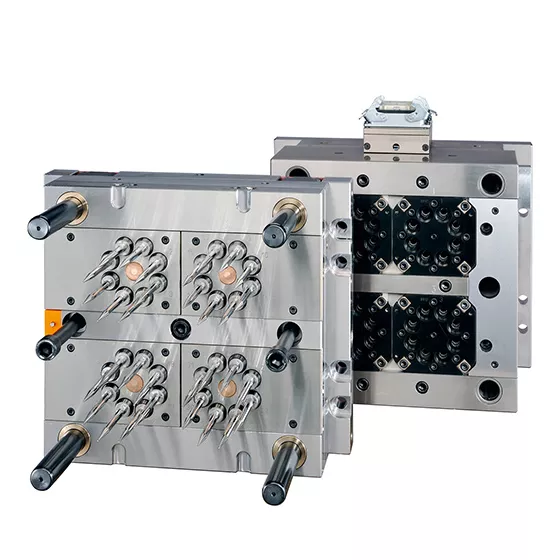

2K molding (2 component molding / 2 Shot molding / 2K injection / Overmolding) is an innovative manufacturing process used to produce complicated molded parts in multiple materials, and can be used for a variety of product designs across all industries.

2K molding (2 component molding / 2 Shot molding / 2K injection / Overmolding) optimises the co-polymerisation of hard and soft materials to create a powerful molecular bond.

Your trustworthy partner

2K Mold Design

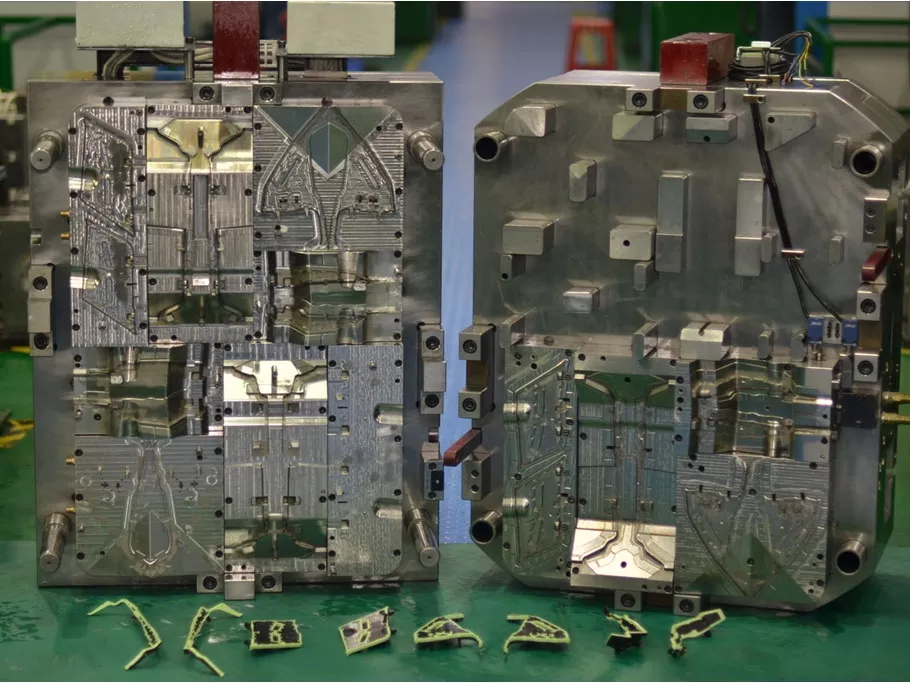

2K mold design is a pivotal factor for molding success. Followings are factors that will make an influence 2k molding: dimensioning and location of the sprue gates, dimensioning of shear edges, flow aids, cooling and ejector techniques, etc. Here at Rjc mold moulding factories, we keep making good 2K mold designs and we are committed to making durable mold that is highly efficient operating and easy to make maintenance and molding production.

The followings are the points that we need to consider during 2K mold design:

- Shrinkage of plastic material

- Wall thickness

- Cavity Numbers

- Plastic material flow systems-Runner and Gate

- Cooling system for around cavity and core

- Ejection System

- Air venting

Advantages of Two Shot Injection Molding

Being the best in the industry doesn’t come by luck; we have invested in technology and state-of-the-art machinery to ensure our clients get the very best for their manufacturing needs. Working with us opens you up to some of the following advantages

What is 2K molding / two-shots molding?

Basic principles of two-color injection mold amount and over molding design.A 2K molding/two-color molding is a mold in which two different plastic materials or 2 colors are molded on the same injection molding machine, the product comes out of the mold only once. It is efficient and economical, and requires a special two-color injection molding machine. Using 2K technology can avoid possible manual assembly steps, cost advantages, design features or aesthetic preferences.

First injection hard plastic material such as (ABS、AS (SAN)、PC、PC/ABS、PE、PP、PS(HIPS,GPPS)、MBS , soft rubber for second molding, such as TPE、TPR、silicon、PVC、TPU、TPV and TPEE, the models applied to handle parts, control buttons and anti-slip applications parts, etc. ……

Transparent plastic material to do the first molding, non-transparent to do the second molding; the plastic part applied to such as electronic cigarettes.

High temperature plastic material to do the first molding, and low temperature plastic material molding temperature to do the second molding.

Applications of Two Shot Injection Molding

Secondary molding is the ideal plastic molding process for complex, multi-color, multi-material plastic products, especially in high-volume production scenarios. Rjcmold serves a wide variety of industries, including automotive, consumer goods, medical, and electronics. The process is particularly useful in applications that require multiple components, intricate shapes, or high precision. Some of the common applications of two shot injection molding include:

Automotive components, such as door handles, steering wheel covers, and instrument panels.

Consumer products, such as toothbrushes, razors, and electronic devices.

Medical devices, such as syringes, catheters, and implantable devices.

Electronics components, such as keypads, switches, and connectors.

Secondary molded components are used in nearly every industry from consumer products to construction, but are most commonly used in applications that require:

- Movable parts or assemblies

- Rigid substrates with soft grip

- Vibration or acoustic damping

- Surface depiction or marking

- Multi-color or multi-material assemblies

We’ve spent the past 20+ years mastering the art and science of two-shot injection molding. Rjcmold has the design, engineering, and in-house tooling capabilities you need to streamline your project from conception to production.

And as a financially stable company, we’re prepared to expand capacity and scale operations as your company and your two-shot needs grow.