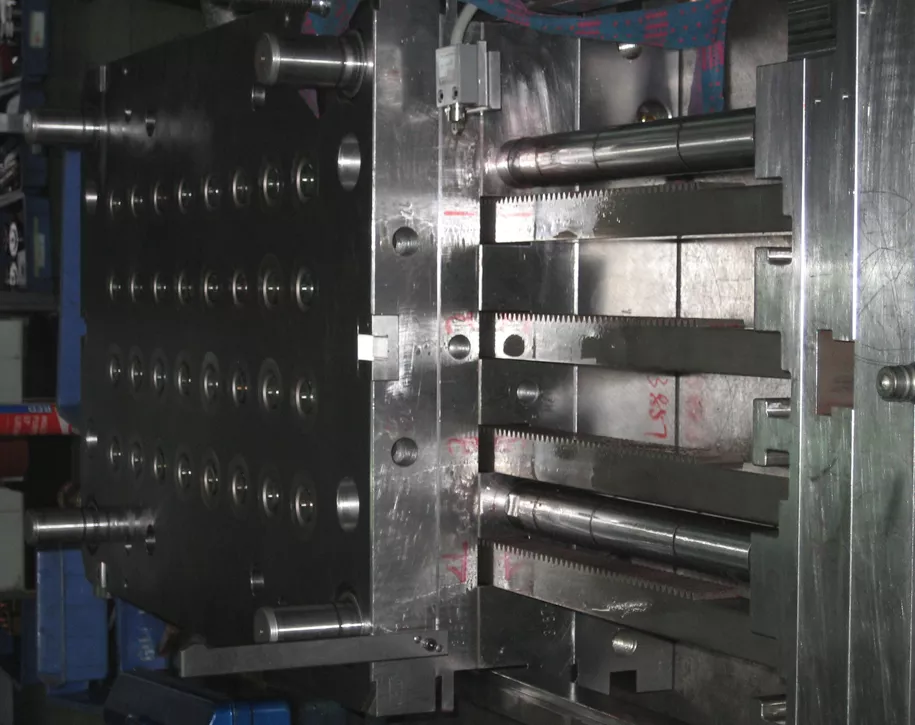

Unscrewing Molds

Whether your mold design calls for 24 cavities or 144 or even 288 cavities, electric, hydraulic or servo actuation, Rjcmold Mold Bases give you the starting point that is most critical, the Mold Base. Tight tolerances and starting with the most stable foundation, “the Mold Base”, is where it all starts. Rjcmold Mold Bases give you that piece of mind.

Unscrewing Molds from Rjcmold Thermoplastic Injection Molding Services

Rjcmold with molds are manufactured with high-precision to meet extremely tight tolerances by using advanced manufacturing processes. This impressive ability allows us to secure the most detailed, complex, and highest-margin molds. We have the expertise to engineer and manufacture molds for a wide range of markets with the ability to integrate complete molding systems within our facility. Our typical mold cavitation ranges from an R&D single cavity mold up to a 192 cavity mold. TSY manufactures single face molds, stack molds, high-speed unscrewing molds, and multi-shot molds where multiple resins and/or colors are utilized.

All of the key molding components are fully inspected using our state-of-the-art inspection lab ensuring that from cavity-to-cavity, mold-to-mold there is 100% interchangeability without any hand-fitting.

If you have any unscrewing injection mold project, you should contact us as soon as possible by email or submit a quote online.Our first engineers has professional knowledge and a lot of experiences for unscrewing injection mold structure,can provide you professional advice, It also is a chance that you can get high quality unscrewing injection molds and make your project success.

Our Unscrewing Mold Service

Over the decades, we have developed special techniques that have established our reputation with unscrewing plastic injection mold manufacturing.The high operation speeds resulting from the quality components and robustness of mechanisms integrated into our molds, make them the first choice for mass production.We can advise and help you establish a reliable strategy from the beginning of your projects.

Rjcmold manufactures high quality unscrewing plastic injectaion molds for threaded parts. We can produce high quality long lasting molds that can increase your speed, productivity and accuracy with higher cavitations and faster cycle times.

Because these threaded plastic parts are typically needed in high volume applications for items such as bottle caps or cosmetics packaging, the unscrewing plastic injection mold most operate at a high speed to reduce cycle times thus reducing part costs. The unscrewing plastic injection molds must also be high quality and reliable to operate for a large number of cycles while only needing routine preventative maintenance. Rjcmold unscrewing molding equipment provides the speed and productivity to produce threaded plastic parts economically.

Our experience includes the use of various rotating core drive mechanisms like, hydraulically driven racks, servo motor drives, planetary gear drives and hydraulic rotating motor drives.

Applications of Rjcmold’s Unscrewing Molds

Our unscrewing mold designs can be used to manufacture a wide range of custom plastic parts or components including, nuts and bolts, sprinkler heads, bottle caps and closures, personal care and cosmetics, automotive parts, and a host of other medical, pharmaceutical, or consumer goods.

For a cost-effective thermoplastic injection molding process, it is critical that molds move at high speeds to clear molded parts quickly and move on to the next cycle immediately.

To increase the productivity of our thermoplastic injection molding company and maximize the performance of unscrewing molds, Rjcmold has developed techniques such as utilizing bearing support cores, robust carriage assemblies, and integral gear/core designs.

Get Quotation Now !

Rjcmold manufactures high quality unscrewing plastic injection molds for threaded parts and is able to warranty them in the USA or China at our mold making facilities. We can produce high quality long lasting molds that can increase your speed, productivity and accuracy with higher cavitations and faster cycle times.

Welcome those customers who needs the similar project come to us for giving you our best mold and parts quotation report and satisfied high quality mold making job in ShenZhen, our factory.