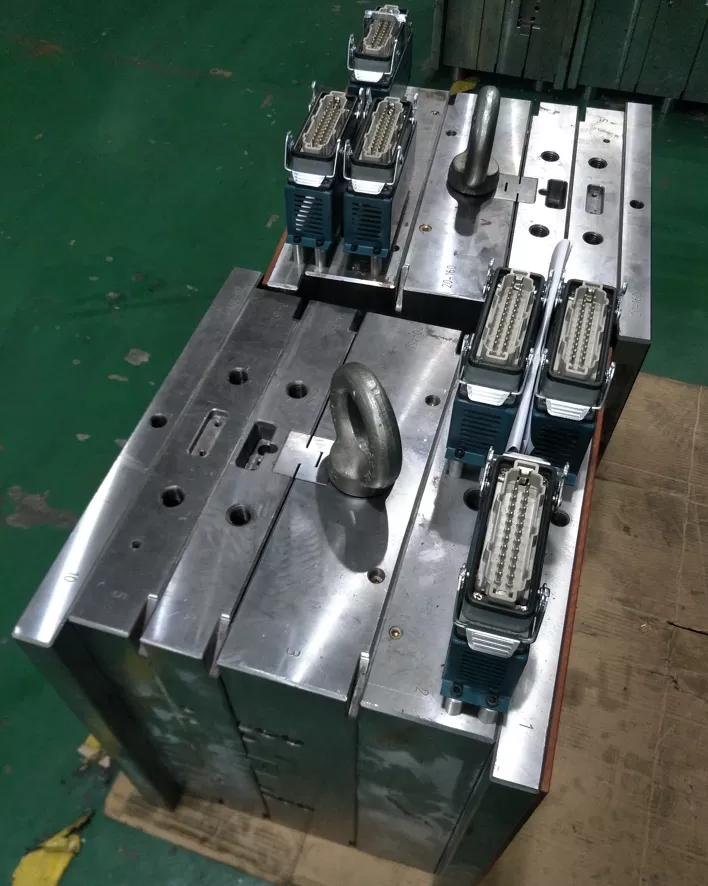

This is Bryan from Shenzhen RJC company, today we’re talking about the connection and application of insert mold and connector.

Firstly, let’s talk about what is a insert mold? It is generally the combination of metal parts and plastic into a new product. There have some ways to go, put the metal parts into the plastic mold then inject plastic material and make them stick together, this kind of products are high precision requirements. In addition, there is hot melt, which is to heat metal parts and then press them into plastic products. Generally, this way only reach the function and don’t need precise requirements. The application of insert mold is very wide and the market demands also very big. Most connectors on the market are manufactured using insert molds. So, you can imagine how big market of insert molds.

A connector is an electronic component used to connect circuit boards, cables, and other devices in electronic devices. And most connectors were made of plastic and metal conductors, however, connectors are used in a wide range of applications and are used in almost all electronic devices. Below are common application scenarios of connectors:

Computer and network equipments

Cell phones and mobile devices

Cars and transportation equipments

Industrial and medical equipments

These products have many kinds of connectors.

For example, the car contains a lot of connectors. The car connector is an important part of the automobile electrical system, which is used to connect various electronic equipment and sensors in the vehicle, including the engine control module, the door control module, the air conditioning system, the sound system and so on. Car connectors are typically required to be waterproof, dust resistant, high temperature resistant, and vibration resistant to ensure reliable transmission of signals and power in harsh working environments.

Here are some common car connector product names:

Antenna connector: Used to connect vehicle antennas and radios, usually including RCA and SMA.

Electric door lock connector: It is used to connect the central lock controller and door lock actuator of the vehicle, usually using the M series connector special for the car.

Headlight connector: Used to connect headlights to the vehicle electrical system, usually with AMP MCP series connectors.

Horn connector: Used to connect the vehicle horn to the sound system, usually the Deutsch DT series connector.

Air conditioning connector: Used to connect the vehicle air conditioning controller and actuator, usually Delphi Metr-Pack series connector.

Compared with traditional fuel vehicles, the current popular new energy vehicles need more connectors and have higher requirements for multi-connectors.

New energy vehicles require higher energy efficiency, so more efficient connectors are needed in all parts of the power system to ensure the efficiency of energy transmission and conversion. A highly secure and reliable power and control system is required. Therefore, the connectors must be protected against water, dust, and vibration to ensure the normal operation of the system and prevent faults. More electronic and electrical equipment needs to fit into a limited space, so connectors need to be smaller in size and lighter in weight to better fit the design and requirements of the vehicle.In response to these needs, the manufacturing of new energy vehicle connectors needs to meet the following requirements: new energy vehicle connectors need to go through high-quality manufacturing and testing, the use of fine processing technology and high-quality materials, to ensure connector performance, high reliability and long life, need to meet certain electrical and mechanical performance requirements, such as plug and plug times, resistance, contact force, etc. For manufacturers, it is necessary to constantly improve the technical level and production capacity to meet the growing market demand, so for insert mold design improvement, processing accuracy requirements, process control need to be further improved.

In terms of plastic materials, it is necessary to have high heat resistance, high corrosion resistance, excellent electrical and mechanical properties. Engineering plastics can meet the requirements of high strength, high temperature and corrosion resistance of connectors. Common engineering plastics include polyamide (PA) and polypropylene (PP).Thermoplastic elastomers can meet the requirements of connectors with high toughness, low temperature bending and heat resistance characteristics, common thermoplastic elastomers are polyester elastomers (TPEE) and polyurethane elastomers (TPU), etc. Silicone rubber has good heat resistance, corrosion resistance and weather resistance, and has good electrical properties, and is widely used in the sealing parts and insulation parts of connectors.

In terms of metal materials, it needs good conductivity and thermal conductivity, corrosion resistance and heat resistance, high strength and wear resistance, commonly used materials including copper, copper alloy, stainless steel, and increase the surface treatment to increase the performance of products, including gold plating, silver plating, nickel plating, etc.

Shenzhen RJC Industrial CO., LTD dedicate in insert molds manufacture more than 20years,and following the new mold technology to meet higher level demands of new products. Support customer’s projects with professional, and developing with customers together. Welcome to contact us or leave message about your opinions for insert molds or connectors developments and manufacturing. Thank you.