Have you heard of Armor Aluminum?

Armor Aluminum isn’t a standardized material name. It’s a general term used to describe aluminum alloys that are lightweight, strong, and impact-resistant.

The term originally came from military use, where special aluminum alloys were developed to meet high demands for strength and impact resistance — especially in armored vehicles, ballistic shields, and naval structures.

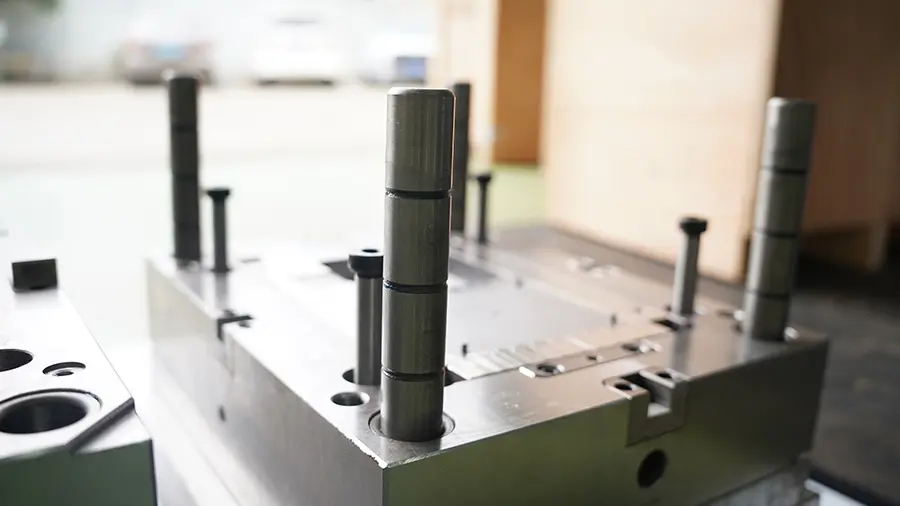

Below are some commonly used armor-grade aluminum alloys, along with their key properties and typical applications:

| Alloy | Series | Key Characteristics | Typical Applications |

|---|---|---|---|

| 5083-H131 | 5000 | MIL-certified; excellent corrosion resistance and energy absorption | Armor plates, military vehicle bodies |

| 7039 | 7000 | Aluminum-zinc alloy; lightweight with high ballistic strength | Military protection, structural panels |

| 2519 | 2000 | Aluminum-copper alloy; high strength, weldable but harder to machine | Blast doors, vehicle armor |

| 7075-T6 | 7000 | Aerospace-grade high-strength aluminum; often used as “industrial-grade Armor Aluminum” | Aircraft parts, high-load components |

Among these materials, 7075 aluminum is the one we encounter most frequently in aluminum CNC machining projects. Known for its excellent strength-to-weight ratio, it’s widely used not only in aerospace and automotive components, but also in consumer electronics where both durability and precision matter.

In fact, many of today’s high-end laptops, smartphones, and camera housings rely on customized 7000-series alloys — often branded as “Armor Aluminum” — to achieve a balance between lightness and structural integrity.

For example, the latest Samsung’s Galaxy Z Fold7 features an Armor Aluminum frame.

In these cases, “Armor Aluminum” is more of a marketing term — designed to signal toughness and advanced engineering.

In Summary:

Armor Aluminum refers to a group of strong, lightweight aluminum alloys originally developed for military use. Today, it’s also used in consumer electronics to improve durability — and to give products a more rugged, high-tech image.

Let me know if you’d like to continue with a section about its CNC machinability, comparison to other materials (like titanium or magnesium), or how to choose the right aluminum alloy for your project. Contact now.