During the injection molding project evaluation stage, “whether to use a hot runner” is often a key decision that affects cost structure, delivery lead time and cycle efficiency, and mass production stability. A hot runner is not “the more advanced, the better”; it is more like an engineering solution oriented to specific product and volume structures: using higher mold investment in exchange for lower unit manufacturing cost, more stable quality, and higher capacity utilization.

What is a hot runner mold, and what problem does it solve?

Simple understanding:

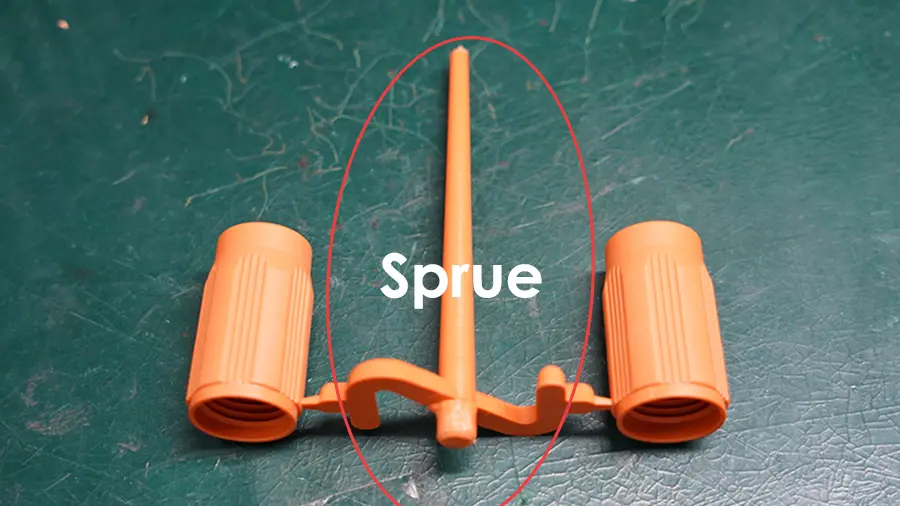

Cold runner: Each injection molding cycle will produce “runner scrap / sprue,” which needs to be removed and trimmed, often causing material waste, increased labor or automation complexity, and appearance/gate risks.

Hot runner: By heating and insulation, it keeps the molten plastic “flowable” inside the mold, reducing or eliminating runner scrap, usually improving molding efficiency and appearance consistency.

You can understand it as upgrading “the part of the mold that delivers plastic” into a more stable and more controllable feeding method.

Therefore, the most common value of a hot runner is concentrated in three things:

Reduce runner waste (especially for products with expensive material and a high runner ratio)

Improve cycle efficiency and automation friendliness (reduce trimming and sprue removal processes)

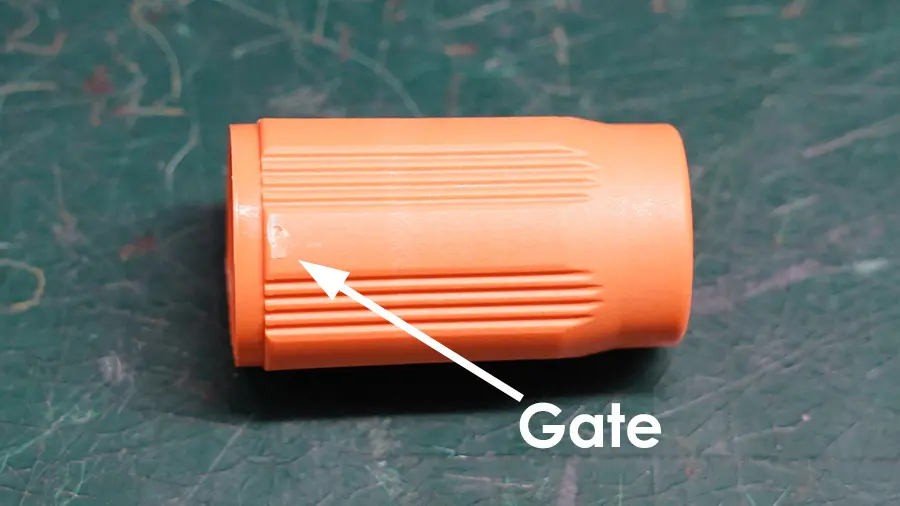

Improve mass production stability (better multi-cavity consistency, more controllable gate vestige, and more friendly for cosmetic parts)

The most suitable product types for hot runner molds (by industry scenario)

The categories below are usually more likely to be “worth it to use a hot runner,” and are suitable as an initial screening reference.

1. High-volume daily consumer goods / packaging: caps, flip caps, pump heads, thin-wall containers, etc.

Typical characteristics: large annual volume, unit cost sensitive; multi-cavity, high throughput; strong automation demand. Hot runners can significantly reduce trimming processes and material loss, and stabilize cycle time.

2. Consumer electronics structural parts / cosmetic parts: housings, decorative covers, panels

Typical characteristics: high appearance requirements (gate vestige, surface consistency); volume is usually large; sensitive to stability and yield. Hot runners are more conducive to making gate and appearance control more consistent and reducing post-processing risk.

3. Automotive parts: interior parts, functional parts, clips, connector housings, etc.

Typical characteristics: long stable supply cycle; high quality system requirements; stronger requirements for multi-cavity and long-term consistency. Hot runners are more conducive to long-term mass production consistency and process stability.

4. Medical / lab consumables: disposable consumables, tubes, small housings, etc.

Typical characteristics: sensitive to appearance, cleanliness, and stability; mostly high-throughput mass production; tend to reduce sprue and manual intervention. Hot runners have more advantages in automation and consistency (still needs comprehensive evaluation combined with materials and regulatory requirements).

5. Engineering plastics / high material cost products: PA, PC, PPS, LCP related parts

When material cost is high and runner waste is obvious, the “material-saving value” of hot runners will be amplified. Especially for small parts with many cavities and a high runner ratio structure, hot runners are more preferred.

Which products are not recommended to use hot runners?

To avoid “hot runner for the sake of hot runner,” the following situations usually require caution:

Pilot production / validation stage: frequent design changes, cold runners are more flexible with lower investment

Low volume, many SKUs, frequent color changes: changeover and downtime losses may offset hot runner benefits

Uncertain orders, short lifecycle: insufficient amortization period, unstable investment payback

Extremely low-cost products with a very small runner ratio: limited savings brought by hot runners

Products highly sensitive to material/process window: not impossible, but requires more sufficient validation and mass production management

In one sentence: hot runner molds are most suitable for injection molded products with large volume, long lifecycle, and high requirements for appearance/consistency/efficiency.

For projects with low volume, frequent changes, and frequent color switching, a more cautious economic and process risk evaluation is needed.

Six core dimensions to judge “is it suitable?”

You do not need to dig deeply into structural details; as long as you evaluate with the following six dimensions, you can basically make a correct direction selection.

Dimension A: Is the annual volume / lifecycle large enough?

Hot runner molds usually have higher upfront investment, but the larger the volume, the faster the amortization.

Large volume, long-term stable supply: more suitable for hot runners

Low volume, frequent revisions / trial-and-error stage: more inclined toward cold runners or a “hybrid solution”

Dimension B: Is the material cost high? Is the runner ratio large?

If the part is very light but the runner is heavy, the material waste of a cold runner will be very obvious. Hot runners have more advantages in the following scenarios:

Engineering plastics, transparent resins, compounded materials with high unit price

Long runners in multi-cavity molds, with a high runner weight ratio

Dimension C: Are appearance requirements high? Is gate vestige acceptable?

For cosmetic parts, transparent parts, and visible surfaces, the value of hot runners is often not only material saving, but also more controllable gate location and appearance consistency, reducing defect risks caused by sprue trimming.

Dimension D: Is it multi-cavity? Are consistency requirements high?

Multi-cavity products (for example 4 cavities, 8 cavities, 16 cavities, or even higher) are more likely to encounter “cavity-to-cavity variation.” Hot runners make stable feeding easier, thereby improving yield and stability.

Dimension E: Do you pursue automation and high throughput?

If you want to achieve automatic part removal, automatic packaging, continuous production, and minimal manual intervention, hot runners usually match this kind of “mass-production” model.

Dimension F: Do you need frequent color changes / material changes?

This is very important: products with frequent color changes and frequent material changes may not be more hot-runner-friendly (cleaning, downtime, and changeover losses must be included in total cost). If your order structure is many SKUs, low volume, and fast changeover, cold runners may be more economical and flexible.

More professional evaluation

If you are evaluating “whether this product should use a hot runner,” you can provide the following information:

Product 3D/2D files or key dimensions and appearance requirements (whether the gate is sensitive, visible surface location)

Material grade/color and color-change frequency, annual demand, and expected lifecycle

Target cavity count, target cycle time or capacity requirements, and whether automated take-out/packaging is needed

Existing issues or focus points (for example: material cost, appearance consistency, yield, delivery lead time)

The Rjcmold engineering team will provide you with feasibility and cost structure evaluation: including volume forecast, material and color changeover, cosmetic surface requirements, cavity planning, and automation concept, and comprehensively provide recommendations and quotations for “hot runner / cold runner / hybrid solution.”