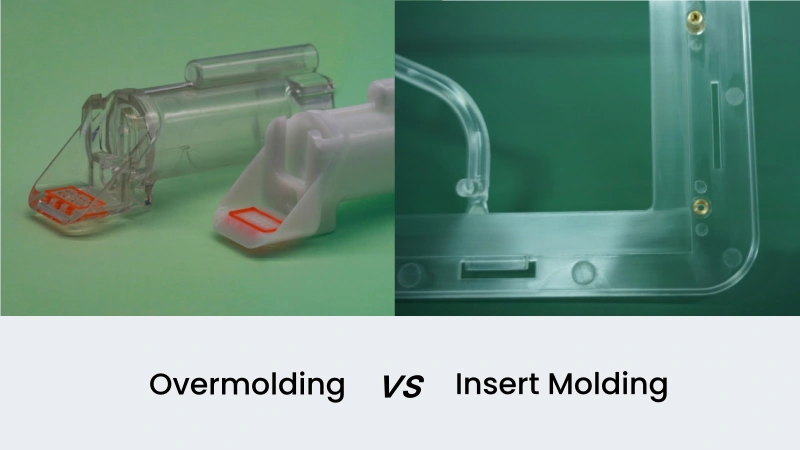

Overmolding and insert molding are two distinct injection molding techniques. Both involve combining multiple materials into a single part, but overmolding focuses on adding a secondary layer for grip or aesthetics, while insert molding integrates pre-made components like metal or electronics for structural or functional purposes.

If you’re an engineer trying to decide which process to use for your next product, understanding these differences can save you time, money, and headaches. Let’s break it down and see how each process works, where it shines, and when to choose one over the other.

What Is Overmolding

Overmolding is an injection molding process in which one or more secondary materials are molded over a previously molded substrate, typically to enhance functionality, ergonomics, or aesthetics. It allows multiple materials—rigid plastics, soft plastics, or elastomers—to be combined into a single part with precise control over material placement.

Think of Overmolding like putting on a second layer of clothing. First, you make the base layer—a solid plastic substrate. Then, in a second molding step, you “add a coat” of another material, often something softer, like TPE or silicone. That’s why it’s sometimes called two-shot molding.

Take a toothbrush as an example. The hard plastic handle forms the base, and the soft rubbery surface added on top makes it comfortable to grip. The result? Better ergonomics and a non-slip surface.

Overmolding is great for products that combine function, comfort, and aesthetics—think medical device handles, electronics enclosures, or stylish consumer goods packaging. The downside is that it’s more complex: two molding cycles mean higher tooling requirements and careful material selection.

Advantages and Limitations of Overmolding

Advantages:

- Combines hard and soft materials in one part, improving grip, comfort, and slip resistance.

- Enhances aesthetics and product functionality, e.g., two-tone designs, sealing, cushioning.

- Reduces secondary operations like gluing or assembly.

Limitations:

- More complex, multi-step process; longer cycle time.

- High tooling cost and upfront investment; better suited for large-volume production.

- Material compatibility must be carefully managed to avoid bonding failures.

What Is Insert Molding

Insert molding is an injection molding technique where a pre-formed component—usually metal, electronic pins, or other functional inserts—is placed into the mold cavity before injecting plastic. The molten plastic then flows around and bonds with the insert, creating a single integrated part that combines the strength or functionality of the insert with the lightweight properties of plastic.

A classic example is a threaded metal insert in a plastic housing. Many plastic parts can’t be tapped directly for screws, so engineers embed metal inserts using insert molding. This ensures the threads are strong, durable, and precisely aligned.

Insert molding is also widely used in electronics, like USB connectors, sensors, or medical electrodes. The main advantage is reducing secondary assembly—you no longer need screws, glue, or extra fixtures, which saves time and labor.

Unlike overmolding, insert molding is usually a single-step process, making it faster and particularly suitable for small to medium production runs in industrial applications.

Advantages and Limitations of Insert Molding

Advantages:

- Integrates metal or functional components with plastic, reducing assembly steps.

- Improves structural strength and functional integration.

- Single-step process; faster and efficient for small to medium production volumes.

Limitations:

- Requires precise positioning and high tolerance of inserts.

- Poorly fixed inserts can lead to defects or waste.

- High demands on mold design and injection control to ensure quality.

Key Differences Between Overmolding and Insert Molding

They may look similar at first, but the difference lies in purpose, efficiency, and end use:

| Aspect | Overmolding | Insert Molding |

|---|---|---|

| Core Idea | Adds a second plastic or rubber layer over a base | Embeds a pre-made component (metal, electronics) into plastic |

| Process Steps | Two or more injection cycles | Single injection cycle |

| Materials Used | Hard plastic + soft TPE, silicone, rubber | Plastic + metal inserts, pins, electronics |

| Production Efficiency | More complex, longer cycle; best for large-volume runs | Shorter cycle; efficient for small to medium runs |

| Primary Goal | Comfort, aesthetics, non-slip, sealing | Structural strength, functional integration |

| Industry Focus | Consumer goods, hand tools, medical devices | Electronics, automotive, industrial components |

| Typical Applications | Toothbrushes, tool grips, phone cases | Connectors, threaded housings, hybrid plastic-metal parts |

In other words, overmolding focuses on feel and appearance, while insert molding focuses on strength and functionality.

How To Decide Whether Overmolding or Insert Molding Is Appropriate for Your Project

It depends on your product’s requirements.

Go with overmolding if:

-

- You want better grip, sealing, or aesthetics

- Your product is consumer-facing and comfort matters

- You plan large production volumes to offset tooling costs

- You want to eliminate adhesives or secondary assembly

Go with insert molding if:

-

- You need structural reinforcement or threads in plastic parts

- You are embedding electronics or functional components

- You want to reduce assembly steps and labor

- You’re producing small to medium batches efficiently

Sometimes, you might even combine the two. For example, insert molding a metal threaded insert first, then overmolding a soft grip on top. This gives you the best of both worlds.

Applications of Overmolding and Insert Molding

At RJC, we apply both insert molding and overmolding across a wide range of industries. Our team of experienced engineers can guide you on the most efficient method for your product, ensuring the best combination of functionality, aesthetics, and manufacturability.

Automotive Industry

In the automotive sector, insert molding is often used to produce fasteners, gears, and other parts that combine plastic, rubber, and metal. Meanwhile, overmolding is ideal for interior components where comfort and style matter—think two-tone handles, knobs, and control interfaces.

Medical Industry

Medical devices rely heavily on plastics for sterilization and safety. Insert molding allows precise integration of functional components, such as pacemakers or internal cameras used for imaging. Overmolding is often applied to handles and housings to improve grip, ergonomics, and patient comfort.

Electrical Industry

Safety and reliability are critical in electrical components. Insert molding and overmolding are used to produce insulated wires, connectors, and housings. Coating wires with rubber-like materials improves safety, while color coding ensures easy identification of live and neutral wires.

Beauty and Consumer Goods

In the beauty industry, overmolding and insert molding allow designers to create packaging that’s not only functional but also visually appealing. From perfume bottles to compact cases, these processes enable custom textures, colors, and ergonomic features. Similarly, everyday consumer goods—plastic containers, plates, children’s toys—benefit from overmolding to improve grip, durability, and aesthetic appeal. Just look around your workspace or home, and you’ll see countless items made using these techniques.

Co-Injection Molding

For projects requiring even more complex combinations of materials, co-injection molding is an option. This process involves injecting elastomers and substrates together, creating parts with advanced functional or aesthetic properties. While more expensive, it’s ideal when multiple materials must work seamlessly in a single component.

Final Thoughts

Overmolding and insert molding aren’t competitors—they complement each other. Overmolding shines in consumer products, where comfort, aesthetics, and sealing are key. Insert molding excels in industrial and electronic applications, where strength and functional integration matter.

At RJC Mold, our engineers are ready to guide you on the right process for your project, helping reduce costs, improve design efficiency, and ensure your parts meet quality and functional goals. Start your project today.