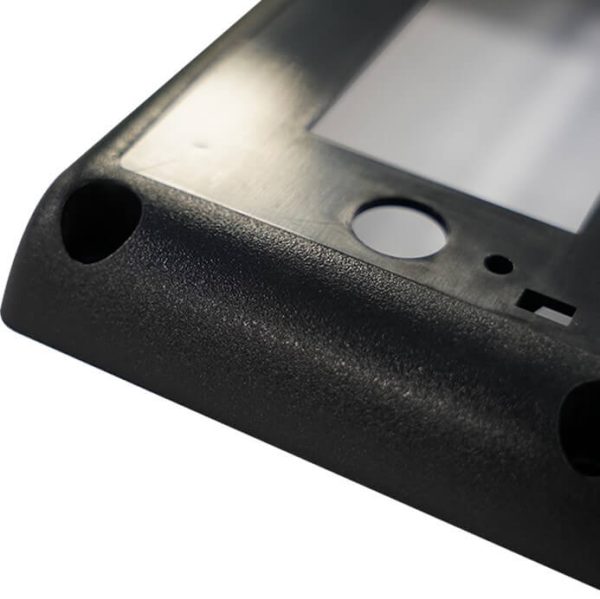

ABS plastic is a solid plastic material used for auto cars, musical instruments, and Lego. Its strong nature makes it suitable for automobile parts.

ABS stands for Acrylonitrile Butadiene Styrene. It is a thermoplastic polymer with no real melting point, this means that when heated ABS plastic doesn’t burn. But rather liquefies, which makes molding easy.

ABS plastic is amorphous plastic and thermoplastic. Meaning that, unlike other materials, ABS responds differently to heat. Unlike thermoset which is only heated once through injection molding.

ABS plastic can be re-heated over and over. Thermoset plastics after the first heating, when heated again, burn. But for ABS plastics, are great materials for recycling.

Once heated at 221 degrees Fahrenheit, ABS plastics melt. Then you can use injection molding to reshape it. You can reuse your ABS plastic after first heating. You can decide to reshape ABS-made Lego into auto-parts.

This is because when heated the plastic does not burn. But instead, it liquefies. So, you can heat and shape. Then cooled, re-heated again, and used for something else.

ABS plastic is eco-friendly. You can easily recycle it. In this article, we will look at things to consider. Especially, when injection molding ABS plastic. But first, what is injection molding?

What Is Injection Molding?

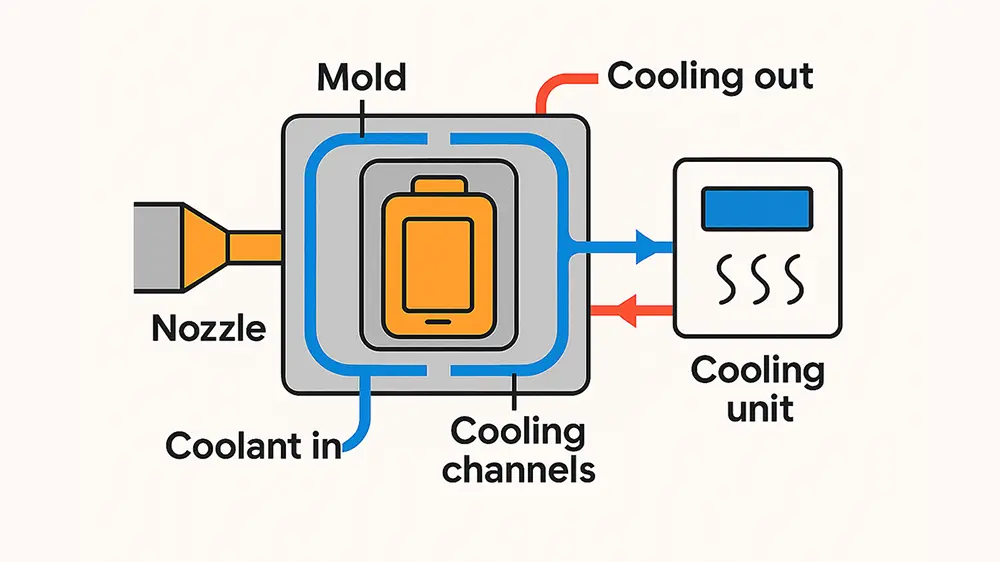

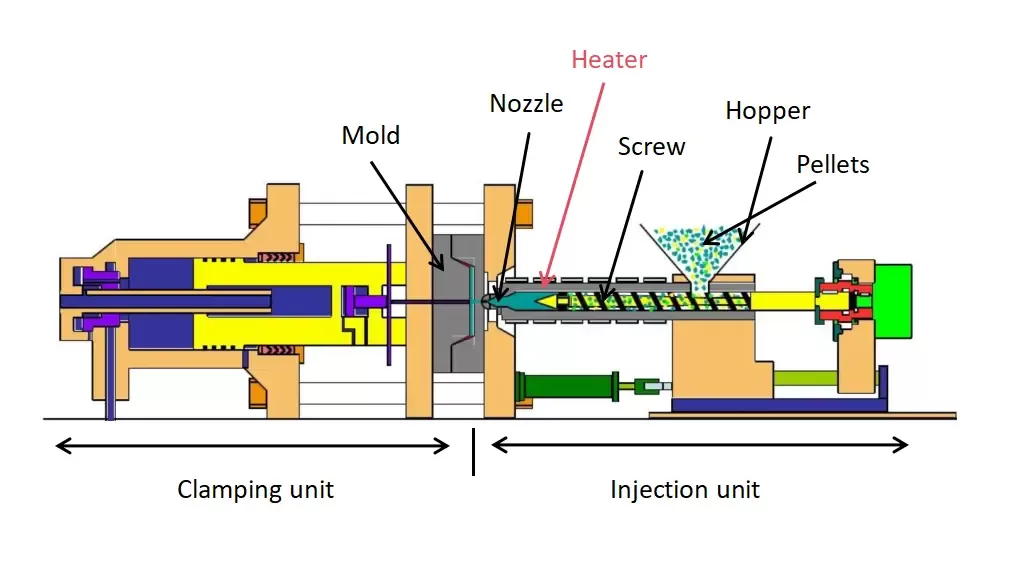

Injection molding is a production process. It enables the mass production of goods with complicated shapes. It is the process of injecting plastic into a mold. This happens after plastic heating.

After the injection, this molten plastic cools, solidifies, and forms shapes based on the mold.

The injection molding process is a large-scale machining production process. This process is used to produce identical daily plastic products in a short period, such as automobile parts, toys, musical instruments, bottle caps, etc. It saves time and effort in plastic production.

Things To Consider In The ABS Plastic Injection Molding Process!

Having understood what ABS plastic and injection molding do mean. Let us go ahead to establish a connection. As both of them are linked, ABS is a cost-saving plastic that can be recycled. And despite recycling, there is no loss of quality while injection molding is used for the mass production of plastics.

So, injection molding is used to create products from ABS. The plastic is injected into the mold after melting. It is cooled and the desired products emerge.

For this process to be effective, there are a few things to look out for. Learn about six key details to consider when injection molding ABS plastic below.

• Plastic Feature

When injection molding, you have to consider the material’s component. In this case, you need to consider the ABS’s features. Understanding ABS’s components help you have the right settings. That is, you use adequate steps for the injection molding.

For instance, if the plastic surface needs to be higher, you will need to use more heat. You will need to control the velocity of infusion.

ABS plastic features an absorbent rate of 0.2 – 0.8%. Also, ABS plastic requires a degree of recycled materials. The recycled materials should not be more than 30%. If it happens to be electroplated ABS, please do not include recycled materials in the molding process. It can cause unwanted harm to your product.

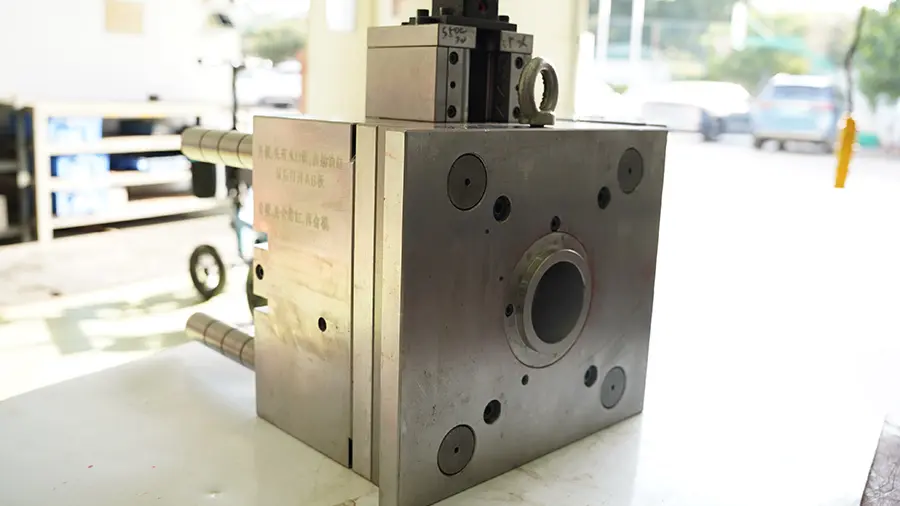

• The Design Of The Mold

Another feature to consider is the mold’s design and gate. This determines the outcome of the molding process. The design of the mold should be equal to its outcome. That is, the same with your desired product. For instance, if you want a rectangular Lego toy. Using a round mold would completely ruin your molding process.

So, when injection molding ABS plastic be careful. It is important that you consider the mold’s design. Although the design varies based on the product. In plastic production, there are some basic standards.

You can set the mold temperature to around 60-65 °C. You can adjust the runner’s diameter to 6-8 mm while its thickness should be equal to the product. That is, the same with your desired product.

Also, it is important that you consider the mold’s gate. The gate’s length should not be less than 1mm while its width should be 3 mm. And its exhaust hole should be 0.025-0.05mm in thickness. And its width should be 4-6 mm.

• Heating Temperature

In injection molding, ABS – the heat temperature is important. The level of the heat determines the melting rate. That is, it determines the rate at which it melts. Know though, that heat temperature is determined by the product. But it also depends on the air injection.

Below are a few suggestions to consider the melting temperature;

1. For the resistance to impact grade. It is suggested that you go for 250 °C. But you can also range between 220-260°C. Whereas for heat resistance, you can range between 265 °C- 270°C. Or choose between 240 °C – 280°C.

2. The transparent grade ranges from 230 °C to 260 °C. But some people might suggest sticking with 245 °C. The electroplating grade ranges between 250-275 °C. Or you can go for 270 °C.

3. There is the flame retardant grade. Then you have the glass fiber-enhanced grade. The first ranges between 200 °C – 240 °C. Or between 220 – 230 °C. While the second range is between 230 – 270 °C.

These are some of the suggested heat temperatures. These you can use for ABS injection molding. Note though, that the temperature depends on the product. E.g. products with high surfaces need to make use of higher heat temperatures.

• Infusion Rate

Let’s move on to the infusion rate. The speed of infusing a liquid into the mold is important. Depending on the product, there are different infusion rates.

For example, it is suggested that you use velocity control of high speed for goods that must have a high surface. Regardless, there is a basic standard that guides you. These guidelines help meet top injection molding of thermoplastic.

When infusing into heated ABS the speed should be fast. This is because the ABS is already heated. While plastic is still in the fire, the rate is slow.

• Back Pressure

Backpressure emerges by the metering of the mixing screw. It means that as the mixing screw works. The material pushes back, even as the ABS is mixed. It is also referred to as plasticizing pressure.

Backpressure is vital in the injection molding process. It ensures a thorough blend of additives and colors. It reduces the pores in the material. It is important in ensuring that ABS is more uniform. That is, thoroughly mixed with fewer bubbles and more gloss, getting the plastic pressure here is key.

Higher back pressure would reduce internal bubbles. It would create a more consistent look for the material. Too much pressure can cause fiber breakage in reinforced resins. While lower pressures might increase pores and allow specks. So, it is vital that you find the right balance. A generally used pressure is 5 bars. But this pressure can be adjusted even during molding.

• Retention Time

The retention time refers to when ABS is subjected to heat during fabrication. This can affect the quality of your product. It can alter the color variation, degradation, and weak parts. It can also affect the performance of your machine which in turn affects the melt temperature. It also spills over and affects everything in injection molding.

The rete time for ABS should not exceed 5-6 minutes. This would help to prevent degradation especially when it is under a heat temperature of 265 °C. And the flame retardant time should be lesser.

But if you need more retention time then you have to adjust the temperature to 100 °C, you balance out things. You do not want your product to decompose. That would be a shame after all your efforts.

Conclusion

Those are the six aspects to consider during injection molding. Remember, that the components of ABS are different. They exhibit different properties than other thermoset plastics. , you have to be careful while melting it. ABS is useful plastic in any industry. You get the best quality from it.

ABS is a strong and delicate substance. Delicate, that it has to follow the right molding process. This is why these tips would save you stress.

Injection molding is a cost-effective procedure when adequately utilized. It allows the mass production of plastic products. Which is done in minimal time and with less effort. It is a mechanized procedure used by various top producers. Most Lego toys are produced using this procedure. So, learn how it has been done. Most especially with a material such as ABS thermoplastic.

For the best possible outcome using the tips stated above.