The essence of medical injection molding is to manufacture medical components and devices using durable, reliable and FDA-compliant medical grade plastic materials. The medical plastic injection molding process is cost-effective and ideal for mass production operations and applications requiring consistency and tight tolerances. This molding process is also used for medical device prototype development and laboratory testing during the FDA approval process.

RJC is a leading supplier of injection molding components for medical plastics. Our medical device plastic and medical device prototype development is among the top in the country. For more information about our medical device plastic and medical injection molding capabilities, please contact us, or send us email [email protected], and we will be happy to resolve any questions you may have.

Advantages of injection molding of medical plastics

Medical grade plastics have become the preferred material for many types of electronic medical devices due to their higher versatility and ability to combine with metals to create enhanced medical product properties. Some of the advantages that medical injection molding companies can offer include:

- Improved ergonomics

- Lose weight

- Adding features

- Lower costs

- Reduce sterilization burden

Why is plastic injection molding important in the medical field?

Since its inception, the use of plastics in modern medicine has steadily increased. Medical devices made from injected-plastic help reduce medical costs, infectious diseases and pain management. High-tech polymers are used in medical device prototyping, often to create improved prosthetics and devices that reduce the risk of infection. Medical plastic injection molding directly improves patient safety and the ability to save more lives.

Injection molding application of medical instruments

Springboard uses our medical injection molding process to manufacture delivery devices for stents, implants, sutures and more. We also provide assembly services for sub-components of larger, more complex medical devices. In addition to medical injection molding, we also manufacture plastic moulds to accommodate other non-plastic parts or mechanisms.

Our medical insert molding process enables the manufacture of enclosures for medical devices, including:

- Medical case

- Medical knob

- The needle

- Surgical instruments and blades

- The pipe

- Dental equipment

- Medical equipment component

- The prosthetic

At Springboard, we use state-of-the-art vertical medical injection molding workstations dedicated to the process of manufacturing parts, components and products for the medical industry. We also have strong relationships with several trusted suppliers who rely on our experience in the industry to provide us with quality metal components for injection molding projects in medical devices.

Pipe forming capacity

Our catheter molding capabilities combine insert molding, micromolding and secondary molding processes with special biocompatible resins. We can manufacture pipe tips, Ruhl joints, joints, marks, manifards, including ceramic or metal parts and assemblies by precision pipe molding as required.

Medical instrument injection molding prototype development

Medical device prototyping requires the creation of fully functional components for testing in the FDA approval process. Springboard uses the most advanced methods and uses the best medical grade plastic materials for our medical device prototype development services. We are aware of the strict regulations required by the medical and healthcare industry and will take all steps to ensure that your prototype meets the FDA class I, II, or II medical device classification required for your application.

Medical molding using medical grade plastic resins

Springboard uses a variety of unique materials for injection molding medical plastics, enabling us to provide the ideal medical plastics for your project needs. We also use a variety of engineered resins in medical injection molding that have excellent mechanical properties, including high tensile strength to resist breaking, and high temperature load ratings to avoid deformation due to heat during sterilization.

Injection molding materials for medical devices

Our medical-grade plastic materials for medical injection molding have high molecular weight and are chemical and heat resistant. Each type of thermoplastic used for medical molding also has different advantages and qualities that you need to review before selecting materials for your injection molding application.

Polycarbonate: Naturally transparent, commonly used in medical tubing, this medical-grade plastic has high tensile, shear and bending strength. It also provides high heat resistance, low moisture absorption, and is stronger than acrylic acid.

PEEK: A special medical grade plastic resin with a high degree of chemical resistance, cracking and fatigue resistance, and can be sterilized by autoclave. It has been approved by the FDA for food contact and has a UL 94 V-0 flammability rating.

Ultem ™ : Used for medical devices and sterilized by autoclave. It resists environmental stresses and cracking, provides excellent dimensional stability and provides excellent strength and stiffness.

We also use several specialty medical-grade plastics with built-in resins and fillers, such as fiberglass carbon fiber, talcum powder, or custom color compounds. This provides some mechanical advantage or other unique properties for the application.

Matters needing attention in choosing medical injection molding plastic materials

Several grades of plastics are available for medical device injection molding and medical device prototype development. Each material has unique properties that determine its performance in the intended application and operating environment. Considerations for selecting the right medical grade plastic material for your application include:

Strength: Plastic resins offer varying degrees of strength, so it is important to ensure that the medical-grade plastic material you choose provides the strength characteristics required for your application.

FDA requirements: Implanted medical devices have different requirements than those used for plumbing, medical devices, and other external uses. Review FDA requirements for your application before selecting materials.

Chemical resistance and heat resistance: Chemical resistance and heat resistance are two key considerations when choosing medical grade plastics, especially if your finished parts must be able to withstand autoclave, gamma ray or chemical sterilization.

Operating environment: Operating conditions determine requirements for strength, heat resistance, chemical resistance, corrosion resistance, exposure to radiation and other factors. Make sure you choose a medical grade plastic material that can withstand your operating conditions.

Molding methods: Medical injection molding and medical insert molding are two commonly used methods in the development of medical device prototype, but not all plastic materials are compatible with these two methods. Before choosing a medical-grade plastic material, it is important to determine which method you will use.

Of all the medical injection molding companies in the industry, Springboard has the knowledge and expertise to help ensure that the right medical grade plastic material is used for your medical device application. We will consider your design, molding methods and application requirements to ensure that you receive finished products that meet your requirements.

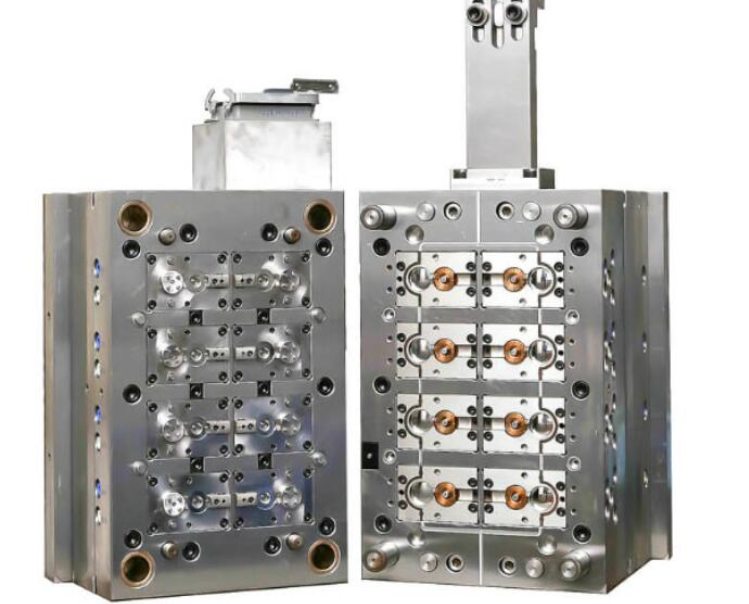

ISO certified medical plastic injection molding equipment

Our expertise in engineered resins and specialty medical plastics ensures that your medical injection molded products meet your exact specifications. We are ISO 13485:2016 certified to conduct comprehensive quality assurance management in the manufacture of medical devices.

Contact us to inform you of your design requirements and we will help you determine the best medical molding process and materials for your application. Some parts may not be suitable for medical injection molding, if this is the case, we will help you find the process that is right for you.

Our goal is to provide medical molding and medical device prototyping solutions within your budget, while providing products that meet your application design requirements. We also understand the importance of providing medical grade plastic materials that are biocompatible and meet the requirements of medical molding regulations.

To complete your medical injection molding or medical device prototype development project, Springboard offers a variety of assistance services including:

- Assembly of molded parts using pneumatic or manual methods

- Ultrasonic bonding creates a lasting bond between two or more components

- Pad printing to add logos, instructions, and other designs to the surface of your molded parts

- Contact RJC for custom Medical injection molding now

- Contact RJCfor more information about our medical plastic injection molding and catheter molding services, or to request a quote now. We are your leading medical plastic injection molding and medical prototype development specialists.

RJC was established in 2002 and engaged in engineering service and technical manufacturing, such as rapid prototyping, mold manufacturing, injection molding, and CNC machining.CNC machining.RJC would be a good vendor choice.

click :https://rjcmold.com/contact-us/

Send inqury.