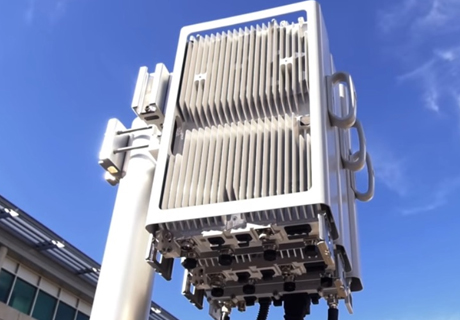

5G Device

The development and future of 5G

As a new type of mobile communication network, 5G, not only to resolve interpersonal communication, but also to provide users with augmented reality, virtual reality, high-definition video, and other more immersive acme business experience. More importantly, we need to solve the problems of man-to-thing and thing-to-thing communication and meet the application needs of the Internet of Things, such as mobile health care, Internet of vehicles, smart home, industrial control, and environmental monitoring. 5G will penetrate into all industries and fields of the economy and society and become a key new infrastructure to support the transformation of the economy and society to digitalization, networking, and intelligence.

With the development and popularization of 5G, it will run through people’s lives in the future. RJC will face this challenge with a new attitude and strive to become one of the most trustworthy suppliers for people to develop together with 5G and participate in it.

What can we do?

A complete 5G base station system consists of BBU, RRU, and antenna. We can make the supporting structural components and RRU shell of the 5G base station, as well as the shell of the 5G router and the metal bracket and shell of the antenna. We work very closely with our clients’ design and procurement teams throughout each project to ensure we deliver quality components according to a schedule they can count on. We also follow our streamlined production process to make sure the right people are in place from receiving orders to delivery.

We have been providing CNC machining services for a wide range of industries and applications for over 20 years. We use the latest CNC technology to manufacture high-precision machined parts.

We have 3, 4, and 5 axis machining centers. The standard manufacturing tolerance for the components is +/-0.001. Tighter tolerances can be specified, but this affects pricing and delivery. Secondary finishes such as tapping, marking and finishing are available on request at an additional charge.

We have extremely experienced design and manufacturing teams, a proprietary manufacturing expert system, and the most advanced injection mold manufacturing and CNC machining systems in our ISO-certified facilities.

Ready to get started? We make it easy!

We encourage you to contact us regarding your next product development project. Our team is ready to provide you designs for manufacturability, design recommendations, and molding services customized to your needs. We will work very closely with our clients’ design and procurement teams throughout each project, and subject matter experts will be involved at every stage to ensure that the components are produced to the exact design specifications — on time and on budget.

In short, we are ready to meet your production needs. Ready to start? We make it easy.