RJC offers prototype and manufacturing services for automotive media and GPS tracking applications. Our manufacturing method results in high-quality, working prototypes. We validate and test prototypes before moving on with manufacturing.

Frequently, we are asked if other components of automobiles may be manufactured using the CNC machining method. In response, RJC can fabricate any element of a vehicle between the headlight covers and the engines. Additional CNC machined components may include cylinder heads, starter motors, gearboxes, and bespoke pieces.

Regarding the CNC machines that RJC uses to fabricate vehicle dashboards and GPS trackers, we utilize a variety of CNC machines to manufacture essential or one-sided automobile components. For cylinder heads and blocks, we use 5-axis machining centers (complex items).

We employ a variety of materials to construct various components of automobiles, including metal and plastic. We use conductive aluminum to manufacture cylinder heads.

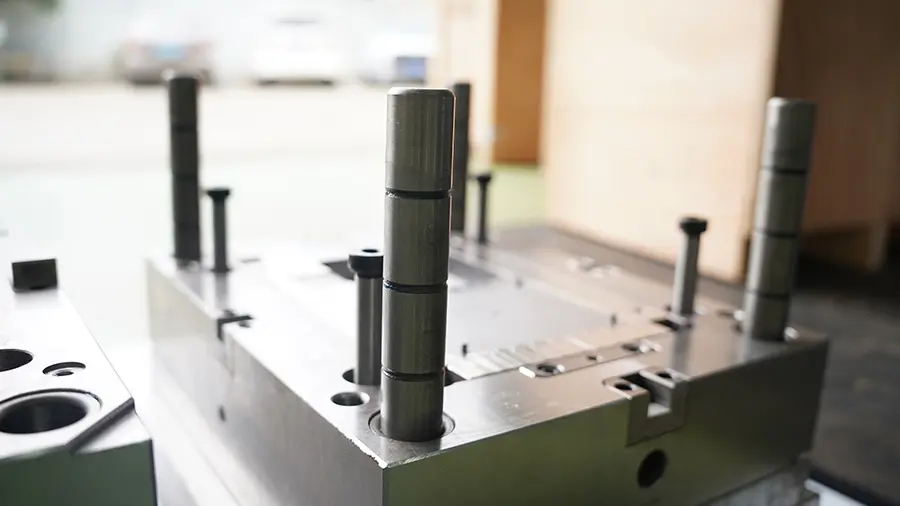

RJC Injection Molding Techniques For Automobile Dashboards

Dashboards are one of the most often ordered components by our clients. Plastic manufacturing is mainly utilized to create automotive dashboard designs. RJC adhered to strict safety and environmental protection protocols when making molds for automobile dashboards. We manufacture dashboards in a variety of techniques to meet the specifications of our clients.

One of the dashboards we created for a customer weighed in at almost 17 kg. It included the dashboard body, the airbag frame, the lower body of the dashboard, the sub-instrument panel body, the interior trim panel, the decorative panel, and the windpipe. We performed some calculations and adjusted the quantity of PP to account for around 80% of the plastic used in the dashboard.

Our standard procedure for fabricating instrumented panels is as follows: the desired plastic is heated and then melts into the mold. The completed product is then chilled. The majority of the time, our rigid plastic instrument panels are made of PP. PC/ABS and PPE comprise the majority of the material composition of instrumented panel skeletons.

Advantages Of GPS Track Housing Production At RJC

CNC machining is widely employed in the manufacture of automobile components across the world. There are several advantages to using CNC machining for manufacturing automobile components such as media, tracker, and other body pieces. These enable increased speed, process automation, and process repetition, resulting in time savings. At RJC, we use cutting-edge molding techniques to create automotive media and GPS monitoring systems. Listed below are many advantages of automobile CNC machining.

- Production speed

RJC ensures that the machining process is fast enough for significant volume manufacturing. Our approach requires less labor and provides a quick and optimal run time throughout the production planning phase.

- Automation

While manufacturing automobile components at the RJC housing production site, we maximize the benefits of automation. Our machining technique incorporates robotic arms that aid in removing the completed product. As a result, employees may devote additional time to design and innovation responsibilities.

- Repeatability

The computerized techniques used in the RJC housing site have the benefit of being repeatable. Our automated industry services are compatible with any industrial-grade manufacturing environment. Our batching procedure is critical to this process.

- Precision

RJC moldings for automobile components and media are precision engineered. We can match automotive parts to any tolerance level, including media, tracks, engines, and other functioning components. As a result, clients always receive precise details of varying degrees of complexity.

- Customization

In terms of customization, RJC additive manufacturing enables the automated industry to create bespoke components. We provide rapid lead times for small batch sizes.

Possible Defects And Their Solution

- Streamline

These types of flaws are caused by changes in the flow rate of molten plastic. These flaws cause the profile orientation of the molds to alter. This sort of fault may occur when the injection rate is too slow, and the plastic solidifies at a different rate than expected.

There are several methods for resolving this issue. One way is to raise the injector’s speed, pressure, and temperature. Following that, gaps should be left between the mold gate and the mold coolant. Thirdly, the diameter of the nozzle should be increased.

- Flow Lines

These flaws are identified by the presence of wavy patterns on the narrow portion of molded components. They come in a variety of colors and ring forms.

These are wavy-like patterns seen on the narrowest area of molded pieces. Flow lines are often a somewhat different hue than the surrounding areas. Alternatively, you may see flow lines as ring-shaped bands. They may develop at mold entry sites. These must be removed because they are deemed inappropriate in some consumer items.

The methods for resolving these are identical to those discussed above in the streamline defection section. Additionally, we may eliminate it by switching to a hot runner or shrinking the main channel’s size.

- Sink Marks

Sink marks are also frequent on injection molded plastic goods. It is caused by the shrinking of the internal plastic substance of the component, which subsequently pushes away from the outside. They have a sunken appearance and are typically seen on flat surfaces. They form as a result of resin flow within the mold cavity.

Material is drawn in from the exterior, forming a visible molding fault. Sink marks can be created by an inappropriate material temperature, excessive pressure used during injection molding, or the amount of time the material remains semi-solid after injection into the mold. These depressions are caused by mold shrinkage when the material cools the following injection into the mold.

These are eliminated by lowering the thickness of the mold material’s wall. Additionally, you can adjust the holding duration and pressure or the cooling time.

- Weld Lines

When two resin-rich plastic pieces are pushed together to create a single part, weld lines occur. While it is usually preferable to avoid weld lines in your product, if they are discovered, everyone, including customers, vendors, and the news media, will want to know why they are there, what caused them, and how we can prevent them in the future. Converging weld lines occur on your part’s vertical surfaces that are bordered by molding ribs. Due to the material’s cooling properties will flow upward to the highest point, accumulating material in some locations and displacing it in others.

These are the solutions: Increase the molten material’s fluidity, temperature, or the amount of releasing agent.

- Burn Marks

Burn marks are the result of poor pressure cooker usage. When using pressure pots for heavier polymers, it is conceivable that the molding material does not completely cool down before the next injection cycle. Due to the weak conductivity of plastics, cooling the hot plastic filler in the mold cavity takes longer. Residual heat tends to continue frying or blistering areas of the molded component surface during this period.

Typical solutions include lowering the melting and molding temperatures or increasing the injection speed and mold cycle system. Integrate exhaust systems

- Discoloration

Suppose you notice streaks or blotches on your part due to discoloration. In that case, this indicates that manufacturing was halted and then resumed. This re-start reinforces your position while weakening its structure, which is why it is more prone to break than the remainder of the molded product. Additionally, discoloration suggests a worse overall quality than a well-pressed portion, as it has not been fully canalized.

Avoid discoloration by using caution while selecting the material for your component. Your material should be resistant to color changes caused by extended exposure to high temperatures, as well as chemical and other substance reactions. When defining material for a mold, consult with a molding specialist to determine which materials are resistant to discoloration from unexpected sources.

To correct this, you can use a purging substance to remove any remaining colorant.

- Delamination

Delamination occurs when the surface layers of a plastic component begin to separate from the core layers. It is a phenomenon that occurs due to various factors:

- Insufficient plastic is injected into the mold.

- The low force is utilized to push the pieces together.

- An excessive amount of moisture within the mold or components.

To correct this, thoroughly clean the mold setup of any impurities.

- Flash

When an edge or angle is removed, flash is the extra flow of material that freezes on the molding surface. If a flash is seen, it may be feasible to complete the mating surface using a rotary tool and/or hand scraper to remove the flash.

The precise reason for flash is uncertain. According to some experts, the cause might be an uneven material flow just past the gate during injection molding. When molten material enters the mold cavity, it may migrate along the mold walls, spilling out onto the part’s surface. The quantity varies according to the melt volume, wall pressure, and transit speed.

To correct this, ensure that the exhaust port is of an appropriate size.