A lot of people think that once they put their idea into a PowerPoint deck or sketch it on paper, they’re halfway to success. The reality? Most ideas that stay on paper never see the light of day. The reason is simple—they never get turned into something tangible, something people can touch and test.

As a product designer with over ten years of experience, I’ve lost count of how many times I’ve seen this. A client will show up with a thick binder of plans: detailed functions, market positioning, even cost projections. But when I ask, “Have you built a prototype?” the answer is usually no. They think prototyping is just a waste of money, when in fact, skipping it is the very thing that kills their ideas.

Rapid prototyping is the only way to prove whether an idea can survive the real world. No matter how polished your pitch sounds, no one invests in imagination alone. Not engineers, not investors, and certainly not consumers.

A Slide Deck Can’t Compete With Something You Can Hold

Take this example: a startup once pitched me on a wireless earbud “more comfortable than AirPods.” Sounds great, right? But all they had were renderings in their slides—no physical model. Investors shut them down with one simple question: “How do we know it’s comfortable if no one can wear it?”

On the flip side, another company wanted to launch a home coffee machine. Nothing groundbreaking in terms of function, but they built three different outer casings through rapid prototyping. Then they invited twenty everyday users to interact with the machines—turn knobs, pull handles, look at the interface. The results were clear: one design stood out as the favorite. That’s the one they took to investors, and they got funded almost immediately.

See the difference? One idea lived only in slides. The other turned into something you could actually test. That gap isn’t small—it’s the difference between failure and survival.

From an Engineer’s Perspective: Prototypes Are Brutally Honest

I’ll be blunt: as an engineer, I have little patience for ideas that never leave paper. That might sound harsh, but it’s true. A pretty drawing doesn’t mean it can actually be manufactured.

I once reviewed a design from a small startup. They had drawn a beautiful curved surface for the casing—sleek, elegant. The problem? With standard injection molding, that curve would trap the part inside the mold. In other words, the design was physically impossible to produce. They only caught the mistake after making a rapid prototype. It cost them two months, but that was still far cheaper than discovering the flaw after spending tens of thousands on a steel mold.

Prototypes are unforgiving, but they’re honest. They don’t care how passionate you are about your idea, or whether you label it “innovative.” They show you what works—and what doesn’t—while the stakes are still low.

The Cultural Gap: Why Silicon Valley Obsessively Builds First

One thing I’ve noticed is how cultural attitudes toward product development differ. In Silicon Valley or Berlin, no one takes you seriously if all you have is a concept deck. Founders there understand the value of speed—they hack together a working prototype, however rough, and put it in front of users. Investors in those ecosystems expect to touch something, even if it’s ugly.

In contrast, many other regions still treat the business plan as the holy grail. Founders will polish slides for months while avoiding the uncomfortable reality check of building something real. It’s almost as if they’re more afraid of failure than eager for success. The irony? By avoiding prototypes, they guarantee failure anyway.

Investors Care About Proof, Not Poetry

Another hard truth: investors don’t fund imagination, they fund execution. When you walk into a pitch meeting, you’re competing with dozens of other founders, all of whom claim to have “game-changing ideas.” What sets you apart is not how poetic your vision sounds, but whether you can show proof of concept.

A rapid prototype tells investors you’re not just a dreamer—you’re someone who can translate vision into reality. It signals that you understand timelines, materials, and manufacturing constraints. More importantly, it shows you’ve tested your own assumptions rather than waiting for someone else to validate them.

Manufacturing Reality Check

Rapid prototyping also shortens the painful gap between design and manufacturing. Anyone who has worked with injection molding or CNC machining knows the risks of skipping this step. A mold can cost tens of thousands of dollars to produce, and CNC setups require both time and precision. If you find out your design doesn’t work only after investing in tooling, you’ve basically set your money on fire.

By creating a prototype early, you save not only money but credibility. Your engineers avoid wasted cycles, your suppliers respect you more, and your investors see you as someone who values efficiency. In manufacturing, time and trust are as valuable as cash.

Why Do Ideas Stay on Paper?

It usually comes down to this: people overvalue the idea itself and undervalue execution.

- Some are afraid of spending money on rapid prototyping.

- Others are afraid of failure, worried a prototype will expose flaws.

- Many simply don’t know better—they think a drawing is proof of feasibility.

In the end, their ideas remain stuck on paper. No market validation, no team buy-in, no investor interest.

The Bottom Line

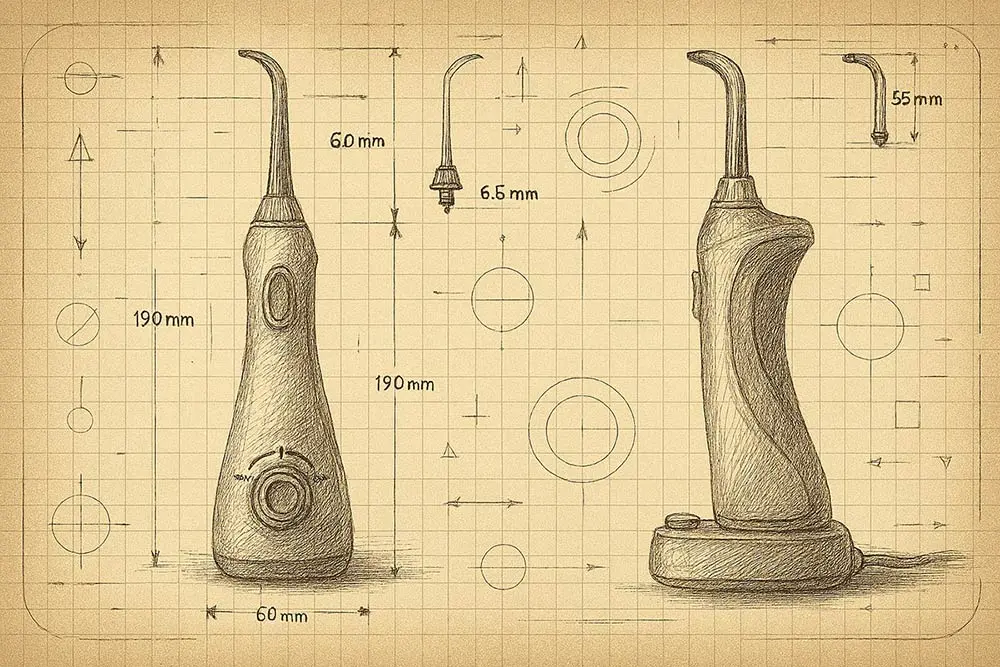

If you truly believe in your idea, stop living in your own bubble with a pretty deck. Build a rapid prototype. Even a simple 3D-printed shell or a rough CNC-machined part will carry more weight than endless slides and sketches.

I’ve seen countless “brilliant” ideas die on paper. The ones that actually make it to market? Almost without exception, they invested in prototypes early on. Ideas are cheap. Prototypes are the real gatekeepers.