Selecting a plastic material is a systematic decision-making process that requires balancing multiple factors. Below is a clear and practical framework to help you choose the most suitable plastic material for your application.

Core Selection Framework: “P.I.E.S.” + Cost

You can evaluate material options using the P.I.E.S. + Cost model:

- P – Performance Requirements

- I – Manufacturing / Processing Method

- E – End-Use Environment

- S – Standards, Regulations, and Safety

- Cost

Step 1: Define Your Application Requirements

(P.I.E.S. + Cost Checklist)

Before selecting a material, answer the following questions as thoroughly as possible.

1. P – Performance Requirements

- Mechanical Properties

- Strength & Stiffness

How much load must the part withstand? Will it bend or deform?

(Reference metrics: tensile strength, flexural modulus) - Toughness vs. Brittleness

Will the part experience impact? Does it need drop resistance or fracture resistance?

(Reference metric: impact strength) - Wear Resistance

Will the part experience friction or abrasion? - Creep Resistance

Does the part need to carry long-term loads without deformation?

- Thermal Properties

- Maximum Operating Temperature

What temperature will the product operate at? Will it contact hot water or heat-generating components? - Minimum Operating Temperature

Will it be used in low-temperature environments? Will it become brittle? - Flame Resistance

Is flame retardancy required? What rating is needed (e.g., UL94 V-0, V-2, HB)? - Electrical Properties

- Is electrical insulation required, or conductivity / antistatic performance?

- Optical Properties

- Transparent, translucent, or opaque?

- Is a high-gloss surface finish required?

2. I – Manufacturing / Processing Method

What manufacturing process will be used?

- Injection Molding

Ideal for complex geometries and high-volume production; requires good melt flow. - Extrusion

Used for continuous profiles such as pipes, rods, sheets, and films. - Blow Molding

Used for hollow products such as bottles and containers. - Thermoforming (Vacuum Forming)

Used for thin-wall packaging products.

Different processes impose different requirements on melt flow index, thermal stability, and processing window.

3. E – End-Use Environment

- Chemical Exposure

- What chemicals will the part contact?

(Acids, alkalis, oils, solvents, cleaners, etc.) - Will it be exposed to water long-term?

Is hydrolysis a concern?

- Outdoor Exposure

- Will it be used outdoors for long periods?

Is UV resistance and weatherability required?

- Special Environments

- Food contact?

- Medical use?

- Long-term contact with the human body?

4. S – Standards, Regulations, and Safety

- Food Contact Compliance

FDA (U.S.), EU 10/2011, GB standards (China), etc. - Medical Grade

USP Class VI, ISO 10993 biocompatibility standards. - Flame Retardancy & Electrical Safety

UL (U.S.), IEC (international) standards. - RoHS / REACH

Restrictions on hazardous substances.

5. Cost Considerations

- Material Cost

Price per kilogram. - Processing Efficiency

Ease of processing, cycle time, scrap rate, yield. - Design Optimization

Can material usage be reduced through smart design

(e.g., uniform wall thickness, reinforcing ribs)?

Step 2: Typical Application Scenarios and Material Selection

Below are common applications and their frequently used plastic materials, provided as a quick reference.

| Application Scenario | Key Requirements | Common Materials | Selection Rationale |

| Housings / Structural Parts(Appliances, Tools, Electronics) | Strength, toughness, cost efficiency, good surface appearance | ABS, PC, PC/ABS, PP | ABS: Good overall mechanical properties, excellent surface finish, moderate cost.PC: High strength and toughness, optional transparency.PC/ABS: Combines PC’s heat resistance and toughness with ABS’s processability.PP: Low cost, excellent fatigue resistance (ideal for living hinges). |

| Transparent Products(Lenses, Cups, Medical Containers) | High transparency, surface hardness, impact resistance | PMMA, PC, PS, PETG | PMMA (Acrylic): Outstanding optical clarity and hardness, but brittle.PC: Extremely impact-resistant, but prone to surface scratching.PS: Low cost, very brittle.PETG: Good transparency, high toughness, easy to process. |

| High-Temperature Components(Electrical Connectors, Automotive Engine Bay, Kettles) | Long-term heat resistance, dimensional stability | PA (Nylon), PPS, PBT, PEI, PEEK | PA: High strength and wear resistance; moisture absorption can affect dimensions.PPS / PBT: Excellent heat resistance and electrical properties.PEI / PEEK: Ultra-high temperature capability (>200 °C) for high-end applications. |

| Flexible Products(Seals, Hoses, Phone Cases) | Flexibility, elasticity, fatigue resistance | TPE/TPU, Silicone, PVC | TPE/TPU: Rubber-like elasticity with thermoplastic processability; widely used for overmolding.Silicone: Excellent high- and low-temperature resistance and biocompatibility.PVC: Low cost; hardness adjustable using plasticizers. |

| Food Packaging & Containers(Water Bottles, Lunch Boxes, Cling Film) | Food safety compliance, transparency, tear resistance | PP, PE, PET, PS | PP: Microwave-safe; widely used for food containers.PE: Flexible; used for plastic bags and cling film.PET: High strength, transparent, good barrier properties (water bottles).PS: Disposable food containers and yogurt cups. |

| Outdoor Products(Lawn Furniture, Logistics Bins) | Weatherability, UV resistance, impact resistance | ASA, Modified PP, PC | ASA: Excellent UV and weather resistance; outdoor alternative to ABS.UV-stabilized PP: Cost-effective solution for outdoor use.PC: High impact resistance, but surface scratches easily. |

| Wear-Resistant Parts(Gears, Bearings, Pulleys) | Low friction, high wear resistance, high strength | PA (Nylon), POM (Acetal), UHMW-PE | POM: High rigidity and very low friction; ideal for gears.PA: High strength and wear resistance, but lower dimensional stability.UHMW-PE: Exceptional wear resistance and impact strength. |

Case Study 1

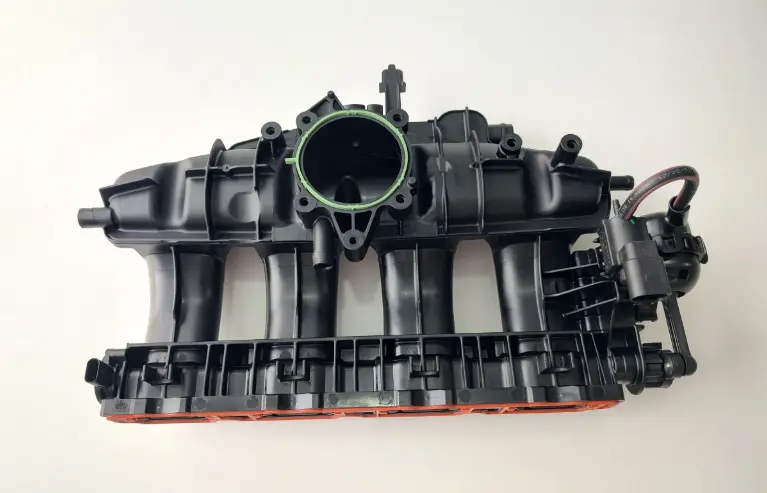

High-Strength, High-Temperature Automotive Engine Bay Component

Example: Intake Manifold

Requirements

- Continuous operation above 120 °C; short-term peaks above 200 °C

- High strength and stiffness to withstand vibration and internal pressure

- Excellent resistance to oil, coolant, and fuel vapors

- Lightweight (metal replacement)

- High dimensional stability under temperature fluctuations

Material Selection Process

Initial Screening

- Commodity plastics (ABS, PC) eliminated due to insufficient heat resistance

- Engineering plastics considered: PA, PPS, PBT

Detailed Comparison

- PA66:

Pros: Balanced performance, high strength, oil resistance, lower cost; glass-fiber reinforcement significantly improves heat resistance

Cons: Absorbs moisture, affecting dimensions and properties - PPS:

Pros: Outstanding heat resistance (>220 °C), near-zero moisture absorption, exceptional chemical resistance

Cons: Brittle, very expensive - PBT:

Pros: Good heat resistance, excellent electrical properties, low moisture absorption

Cons: Lower impact resistance; limited hot-water resistance

Final Selection

- PA66 reinforced with 30% glass fiber (PA66-GF30) is the most common choice, offering the best balance of performance and cost

- PPS is used for components near turbochargers where extreme temperatures justify the higher cost

Conclusion: PA66-GF30 is the preferred solution.

Case Study 2

High-Appearance, Electroplated Consumer Electronics Housing

Example: Bluetooth Speaker Enclosure

Requirements

- Premium surface appearance suitable for painting and electroplating

- Good strength and impact resistance for daily use

- Adequate stiffness for structural integrity

- Good flowability for complex geometries

- Controlled cost

Material Selection Process

Initial Screening

- Electroplating requires amorphous or lightly crystalline materials with good adhesion

- ABS is a classic electroplating material

- PC/ABS considered to improve strength and heat resistance

Detailed Comparison

- ABS:

Pros: Excellent plating adhesion, low cost, easy processing

Cons: Lower strength and heat resistance - PC/ABS:

Pros: Combines PC’s strength and heat resistance (110–120 °C) with ABS’s processability and plating performance

Cons: Higher cost than ABS - PC:

Pros: Outstanding strength and toughness

Cons: Poor plating adhesion, higher cost, internal stress risk

Final Selection

- PC/ABS is the optimal choice for mid- to high-end Bluetooth speaker housings

- ABS may be used for cost-sensitive, low-strength applications

- PC is generally not recommended for electroplating

Conclusion: PC/ABS is the preferred solution.

Step 3: Practical Material Selection Workflow

- Define Requirements

Create a detailed checklist and distinguish between “must-have” and “nice-to-have.” - Initial Screening

Narrow down to 2–4 candidate materials. - In-Depth Comparison

- Review datasheets from suppliers (SABIC, DuPont, BASF, Dow, etc.)

- Evaluate compatibility with existing manufacturing equipment

- Prototyping & Testing

- Build prototypes using candidate materials

- Perform drop tests, thermal aging tests, chemical resistance tests

(This is the most critical step.)

- Final Decision

Select based on test results, cost analysis, and supply chain stability.

Summary

There is no “best” plastic—only the most suitable one.

Successful material selection comes from a deep understanding of the application and a systematic evaluation process. When in doubt between materials, building prototypes and conducting real-world testing is the most effective way to reach a confident decision.