What is Overmolding?

Overmolding is a two-shot plastic injection molding process that creates a single part by combining two different but complimentary thermoplastic materials.

The first shot, the substrate, is usually composed of more rigid plastic and is designed to accept the second shot, called the overmold. The overmold is typically composed of a softer, more flexible plastic-like rubber.

By mechanically or chemically bonding two plastic materials, the overmolding process can help product designers achieve additional functionality or aesthetics that would otherwise not be practical.

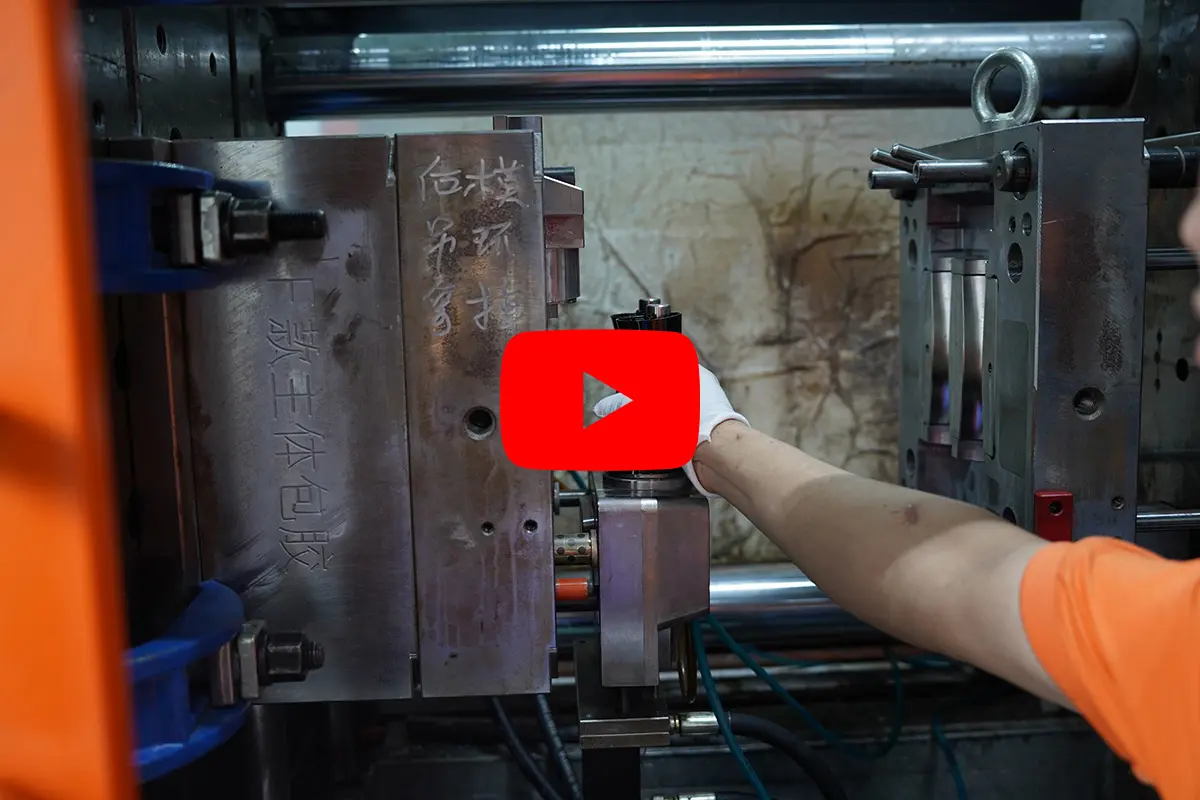

Our Overmolding Capabilities

RJCmold’s custom overmolding services ensure the creation of plastic parts that look and perform better. Our production line consists of an overmolding injection molding process that allows us to combine several different materials into one, ensuring you get superior-quality products.

| Standards | Metric Units | Imperial Units |

|---|---|---|

| Maximum Part Size | 200×400×100mm | 7.87×15.75×3.94in. |

| Minimum Part Size | 2×2×2mm | 0.08×0.08×0.08in. |

| Substrate Wall Thickness | From 0.5 to 3mm | From 0.20 to 0.12 in. |

| Tolerance | +/- 0.025 mm | +/- 0.00098 in. |

| Radii | 0.1mm | 0.0039in. |

| Depth | 100mm from the parting line | 3.94in. from the parting line |

| Mold Validation | Provide T0, T1, T2 samples before mass production | |

| Inspection and Certification Options | First Article Inspection, ISO 9001, ISO 13485 | |

| Lead Time | From mold making to sample delivery: 15-45 business days |

Overmolding Design Tips

Wall thicknesses between 0.060″ to 0.120″ (1.5 mm-3 mm) generally provide the best bonding.Keeping radii between 0.020″ or 0.5mm minimum in corners reduces localized stresses.

If the part requires thick TPE sections, they should be cored out to minimize shrinkage problems, reduce the part weight, and lower cycle time.

Avoid deep or un-veritable blind pockets or ribs in your design.Use gradual transitions between wall thickness to reduce or avoid problems with the flow (backfills, gas traps, etc.)

The TPE/TPV should be less thick than the substrate to prevent warpage, especially if the part is flat, long, or both.

Overmolding needs mechanical or chemical bonding to the substrate, so your material choices should enable this.

Applications of Overmolding

The injection overmolding process is compatible with a wide variety of materials, ranging from plastics to metals. This process helps produce custom prototypes and production parts for various applications depending on your requirements. Several industries find valuable uses for overmolding services.

Contact RJCmold for Custom Plastic

Overmolding Services Today

RJCmold provides the end-to-end overmolding molding services you need to stay ahead of the game. Our team stable of state-of-the-art tooling and design capabilities combined with over 300,000 square feet of on-site production space allows us to create high quality molded parts designed to your project’s exact specifications . Read about our other plastic molding capabilities here. Request a quote today to begin discussing your overmolding requirements. Contact us with any questions.