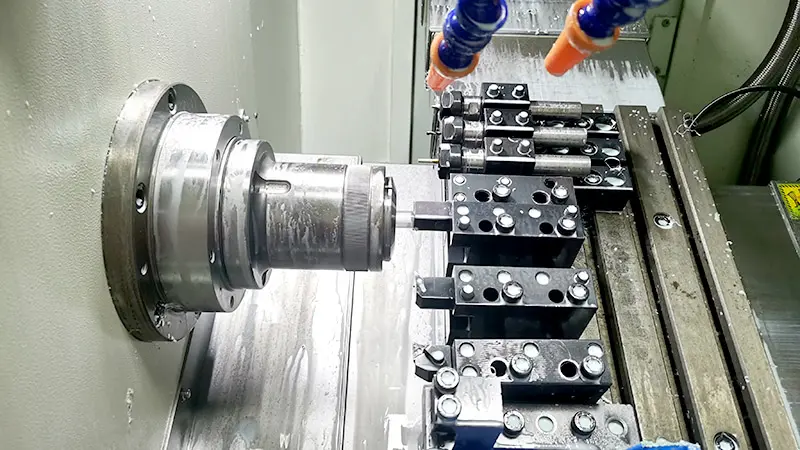

Our CNC Machining Capabilities

We provide a full range of CNC machining services, from single prototypes to large-scale production, all with tight tolerances.

CNC Machining Materials

The following is only a partial display of materials. Please contact us for more materials.

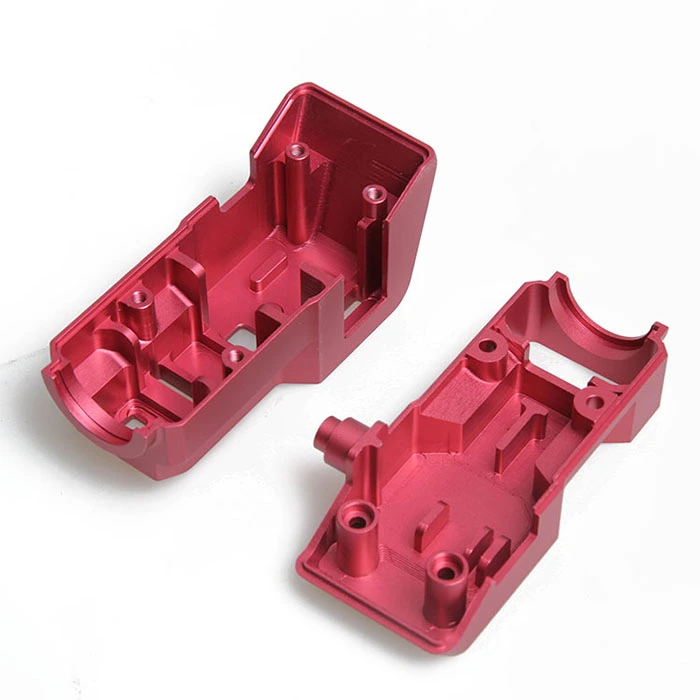

Aluminum

Features & Uses: Lightweight, corrosion-resistant, excellent machinability; common alloys include 6061 and 7075 for prototypes, enclosures, jigs, and aerospace/auto parts.

Surface Finish: Bead blast + anodizing (clear/black/colors), chromate, polishing.

Surface finishes of CNC machining service

Choose from dozens of surface finishes for metals

Common Metal Finishes (Set A)

• Anodizing (Type II/III) — corrosion resistance, colors (Aluminum)

• Powder Coating — durable colored layer, outdoor-friendly

• Electroplating (Nickel/Chrome/Zinc) — wear & corrosion protection

• Bead Blasting + Brushing — uniform satin texture, de-glossing

• Polishing (Mirror) — high reflectivity for cosmetic parts

Common Metal Finishes (Set B)

• Passivation (Stainless Steel) — enhances corrosion resistance

• Black Oxide (Steel) — low-gloss black, anti-rust oil compatible

• Zinc/Nickel Plating — sacrificial protection for steel hardware

• Hard Anodizing (Type III) — thick, wear-resistant ceramic layer

• Chromate Conversion — conductive corrosion protection (Al)

Common Metal Finishes (Set C)

• Bead Blasting — fine matte texture, hides machining marks

• Brushing (Hairline) — directional grain for premium look

• Electropolishing — smooths micro-peaks, brightens stainless

• Phosphate (Parkerizing) — oil-holding layer for steel parts

• Clear/Black Anodizing — classic appearance with protection

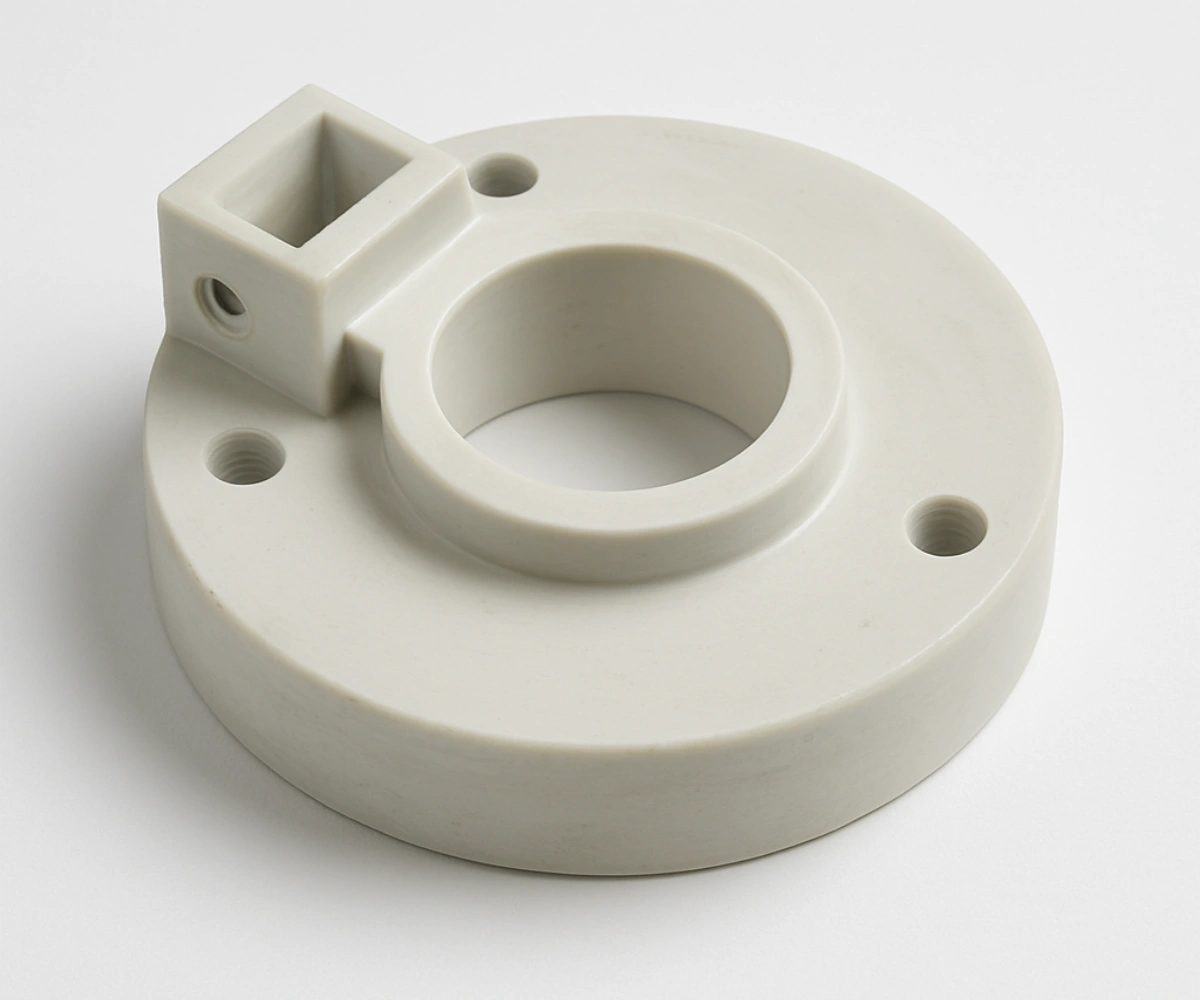

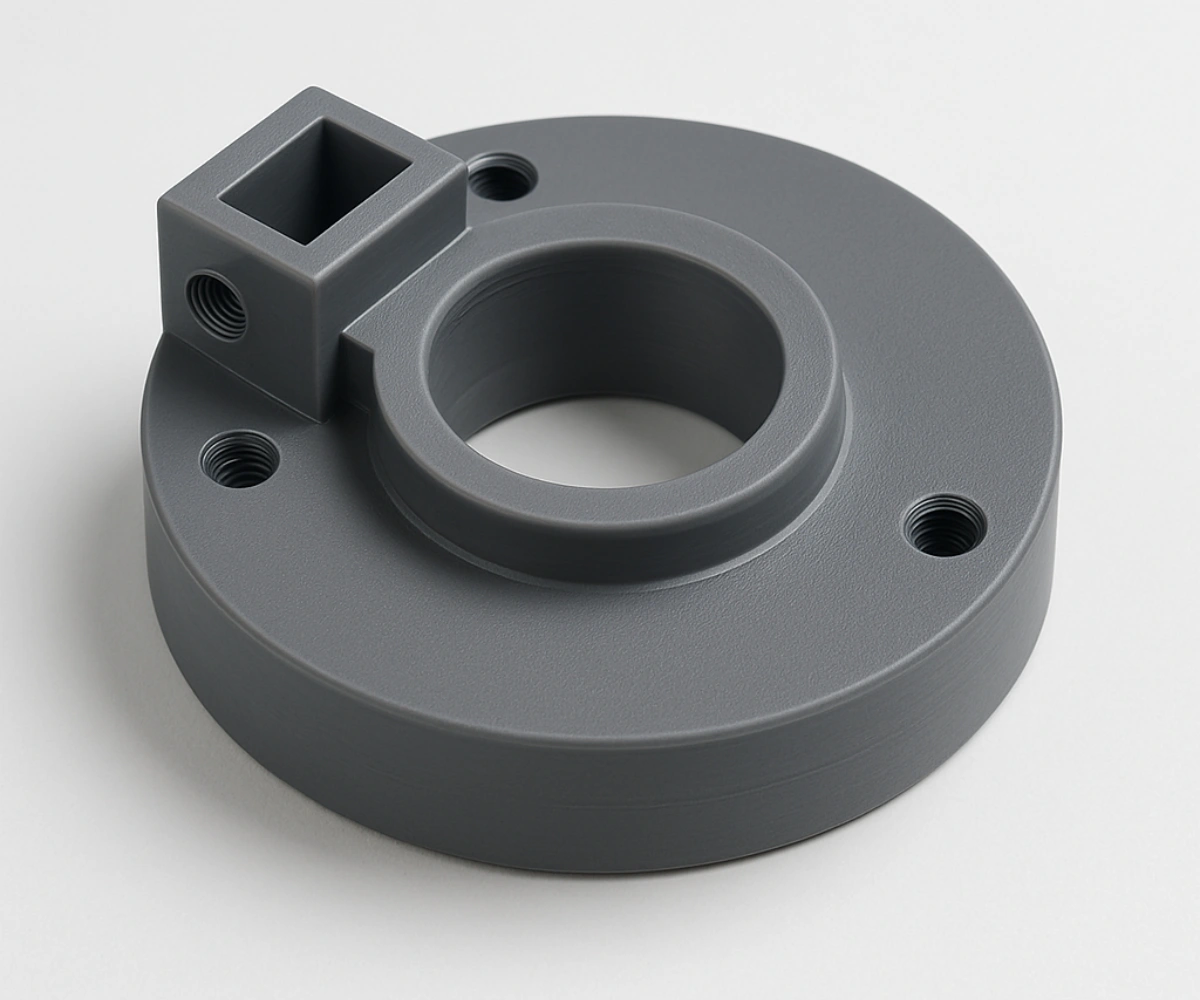

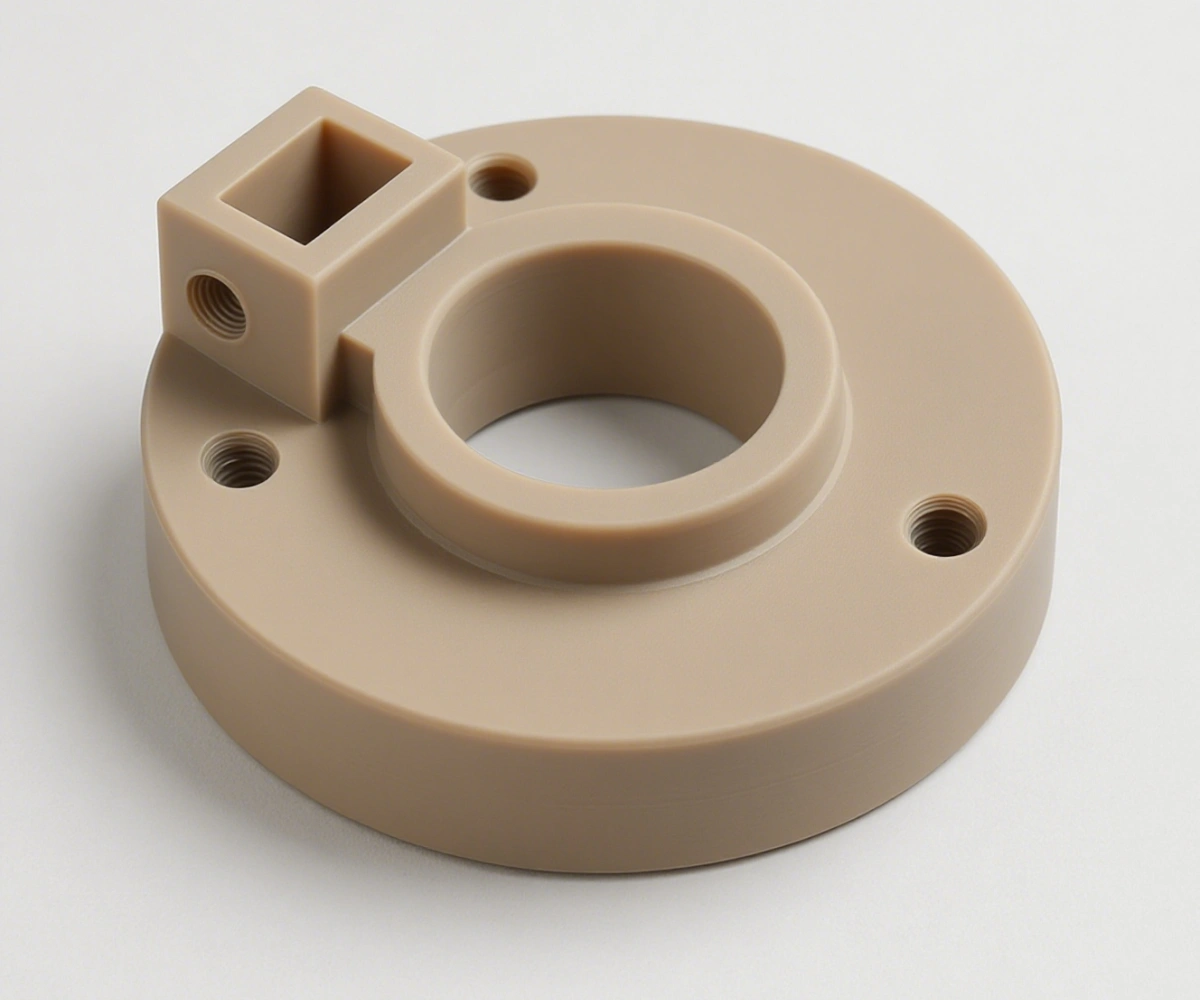

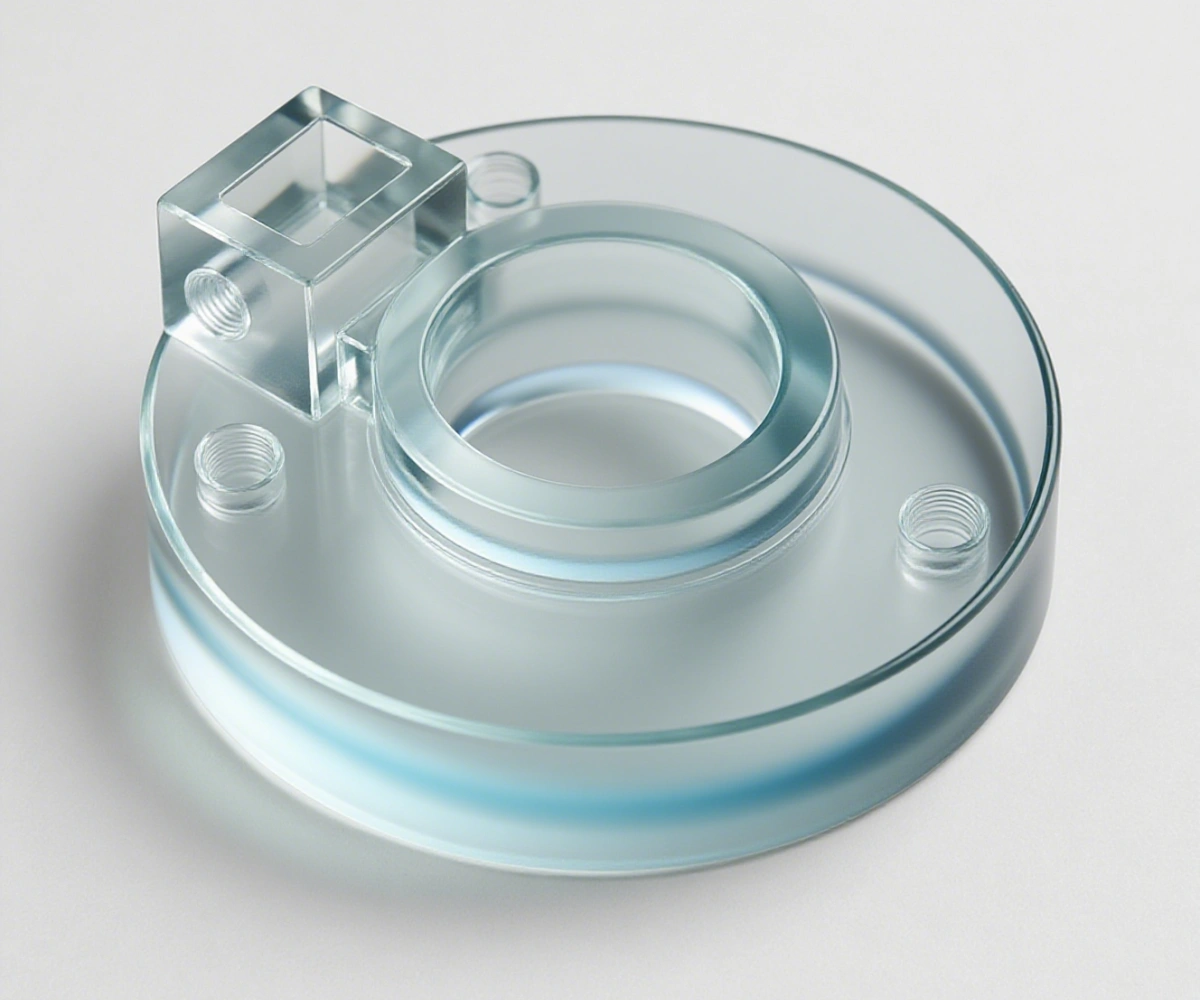

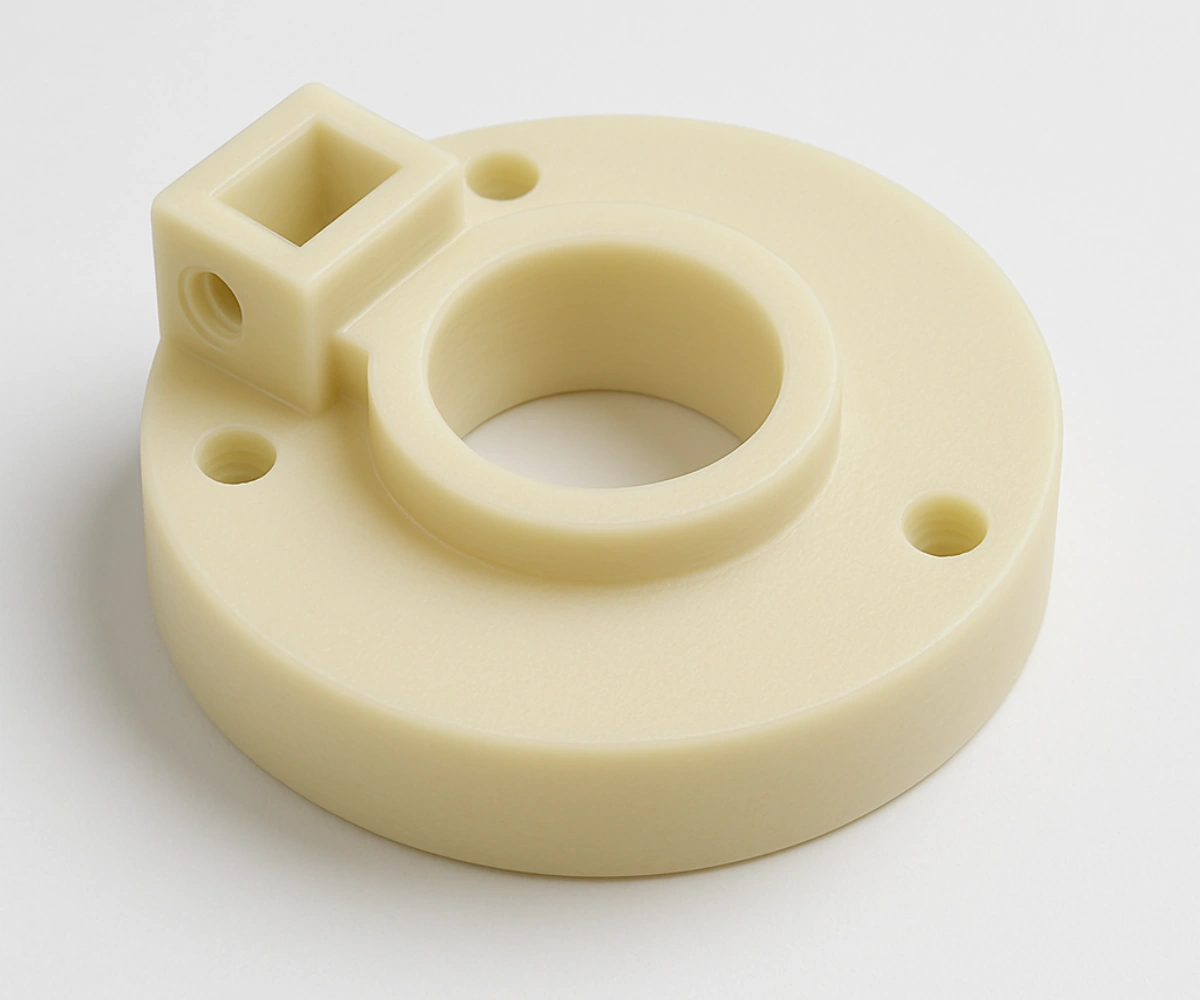

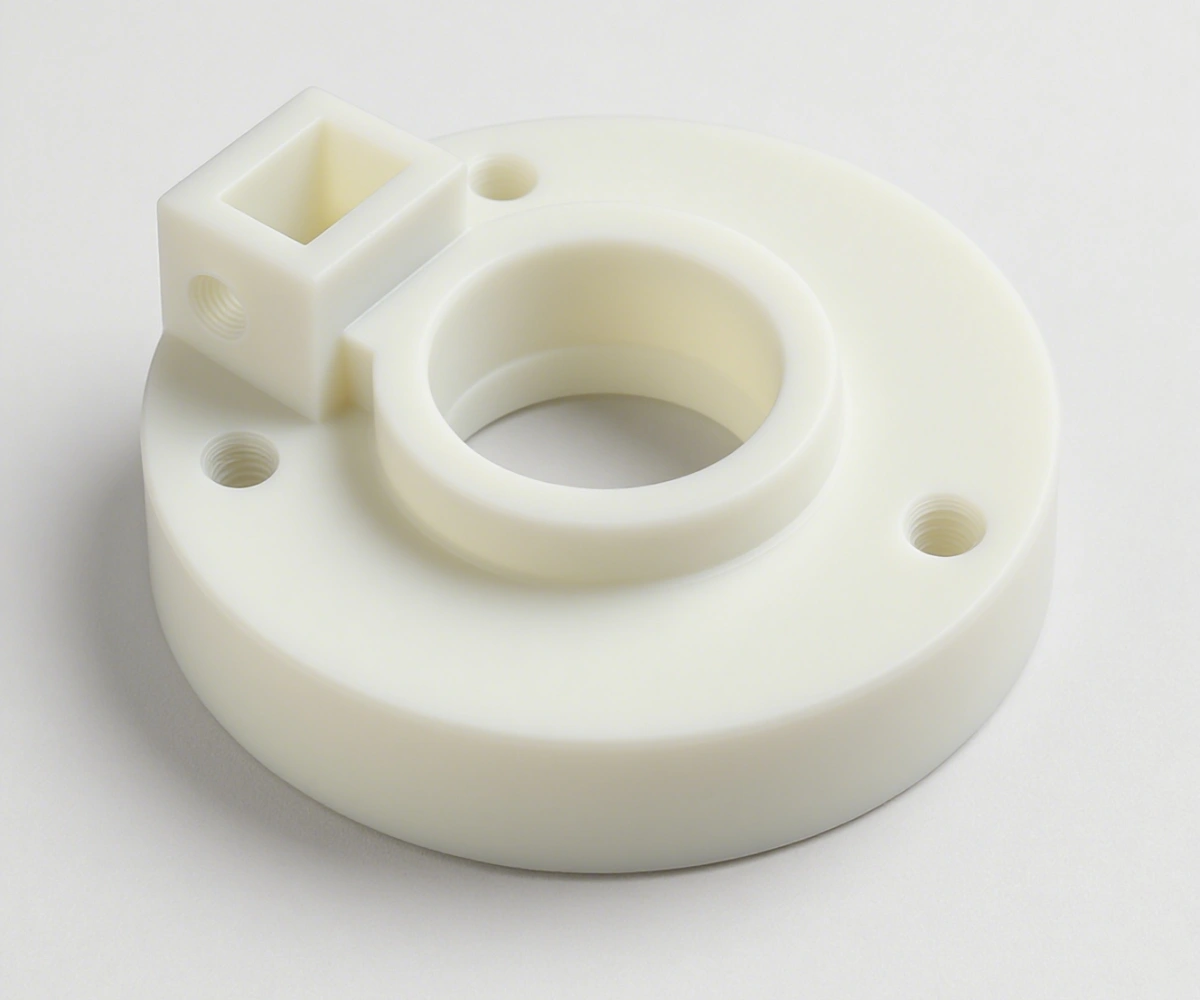

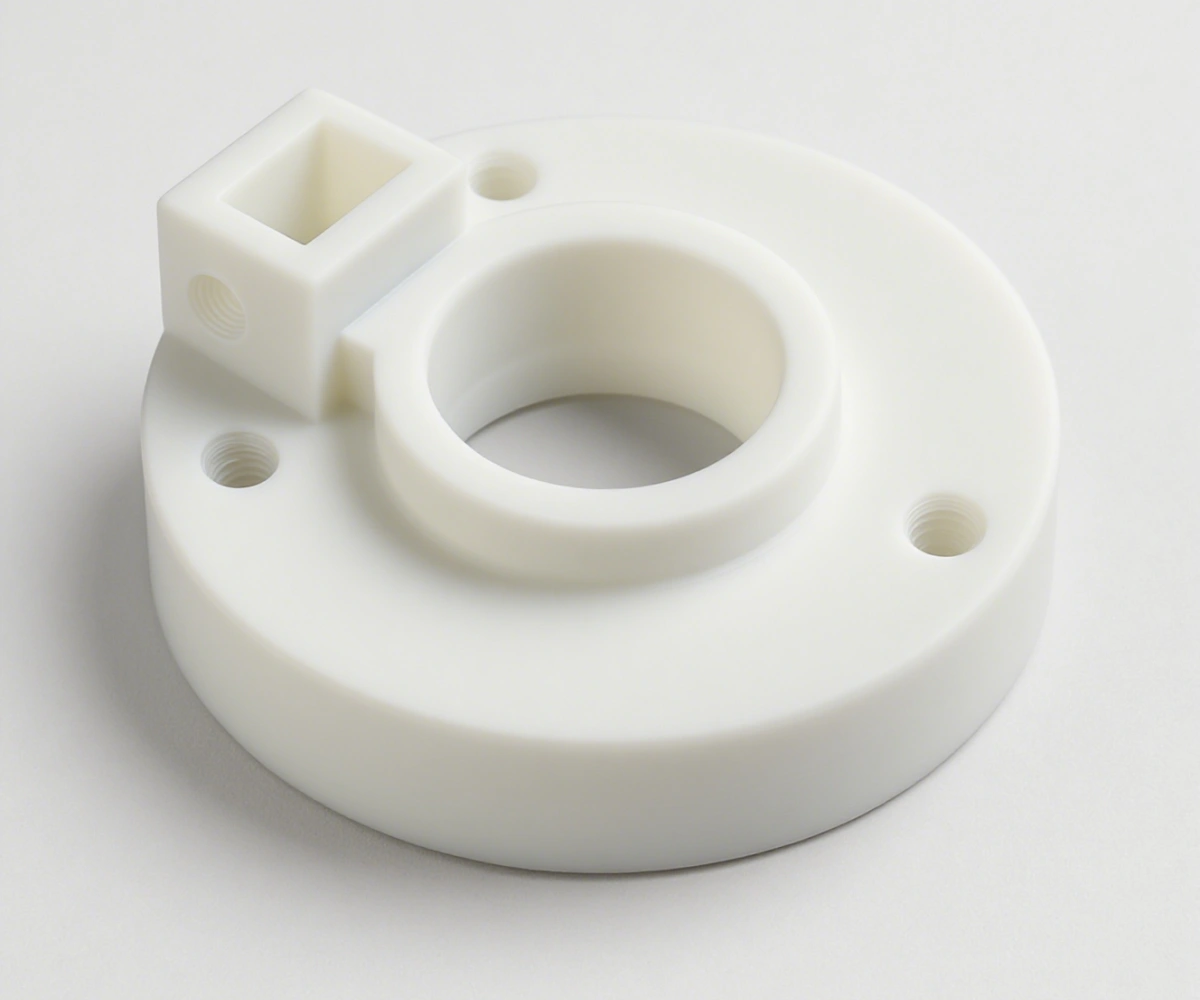

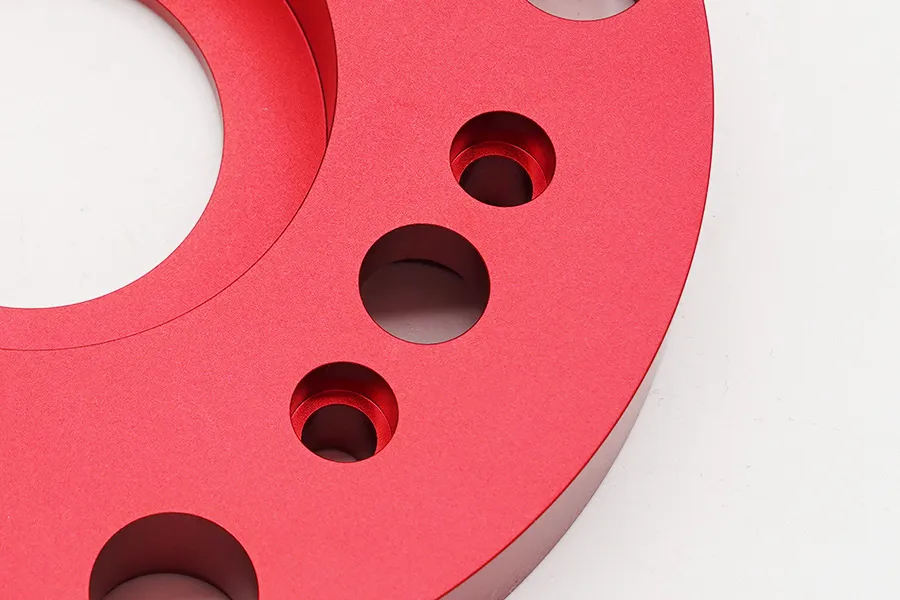

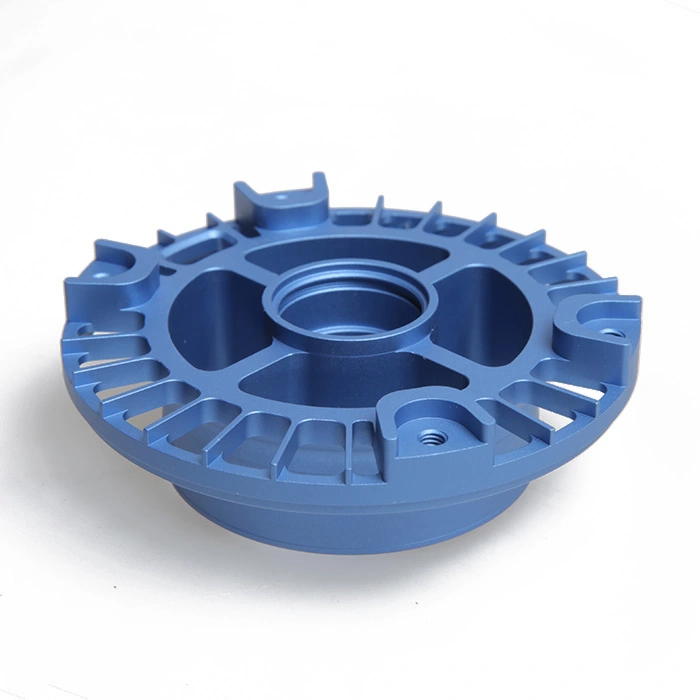

CNC machining parts sample

Explore our CNC machining projects to learn more about the ways that our work creates an impact.

FAQS

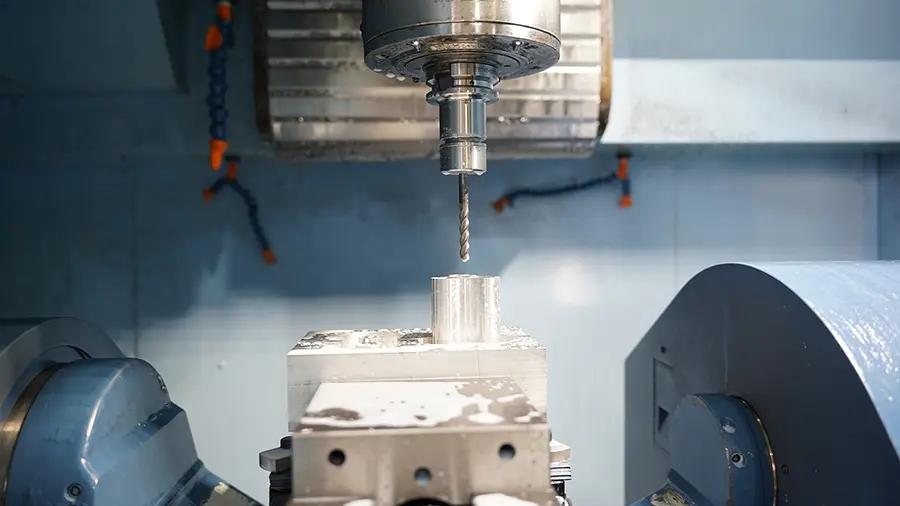

Subtractive manufacturing (CNC machining) is a machining process in which machines carve a solid piece of raw material into a desired 3D geometrical shape and size using a controlled material removal process. This process relies heavily upon the use of machine tools and power and hand tools.

The application of Computer Numerical Control (CNC) matches the need of the modern industry. CNC uses computers to control the movement and operation of mills, lathes, and other cutting machines. However, subtractive manufacturing is broadly adapted to manufacture metal products, wood, plastic, ceramic, and composites materials.

Historically, the subtractive machining process was manual. Processes such as woodcarving, forging, and filling of metals, once done by hand, have undergone rapid advancements over the past century and now broadly incorporate technology that makes them more efficient and precise.

Undoubtedly, there are several benefits of using CNC machining. Here are some of them.

- You can accurately produce high volumes of the same part with precise dimensions. If manually done, this is a mundane and repetitive task which will definitely lead to errors and lack of precision. By partnering with a precision CNC machining services provider, you can be assured of structural and dimensional accuracy of parts, regardless of the volume required.

- It reduces time and increases productivity or OEMs, quick assembling, as well as time to market of products.

- Since this is subtractive manufacturing technique, CNC machining leads to less wastage. With the design already in place, one can rightly estimate the material quantity, and other aspects.

- Once you select and run the right software program, the production will go on in iterative looping manner, till the machine is stopped. In fact, in automated process, you can set the volume and the machine will automatically stop once the required number of parts are produced.

- CNC machining definitely wins on the safety aspect. It isolates workers from operating machines, which reduces the risk of accidents and injuries.

- Fast turnaround times and accuracy provided by CNC machines helps OEMs across industries save resources and energy.

- Maximum Part Size: Milled parts up to 80” x 48” x 10” (2,032 x 1,219 x 254 mm). Lathe parts up to 62” (1,575 mm) length and 16” (406 mm) diameter.

- Standard Lead Time: 3 business days

- General Tolerances: Tolerances on metals will be held to +/- 0.0007″ (+/- 0.02 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.002”.

- Precision Tolerances: RJC can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts.

- Minimum Feature Size: 0.020” (0.50 mm). This may vary depending on part geometry and chosen material.

- Threads and Tapped Holes: RJC can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

- Edge Condition: Sharp edges are broken and deburred by default

- Surface Finish: The standard finish is asmachined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

- Internal corner fillets: Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii.

- Floor fillets: Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior.

- Undercuts: Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool.

- Tapped/threaded hole depth: Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads.

- Complexity: Keep the number of small cuts to a minimum to reduce costs; only design in the necessary features to balance function with aestheti

|

Limits for nominal size |

Metal (ISO2768-m) | Plastic |

|---|---|---|

|

0.5mm to 3mm |

±0.05mm |

±0.1mm |

|

Over 3mm to 6mm |

±0.05mm |

±0.1mm |

|

Over 6mm to 30mm |

±0.1mm |

±0.2mm |

|

Over 30mm to 120mm |

±0.15mm |

±0.3mm |

| Over 120mm to 400mm | ±0.2mm |

±0.5mm |

| Over 400mm to 1000mm | ±0.3mm |

±0.8mm |

| Over 1000 mm to 2000mm | ±0.5mm |

±1.2mm |

| Over 2000mm to 4000mm | ±2mm |

How we guarantee quality:

✓ 5-step inspection protocol (From raw material to final packaging)

✓ 18 high-precision CMMs (Mitutoyo & Zeiss, calibrated weekly)

✓ 100% traceability (Real-time production tracking via ERP)

✓ Zero defect escalation (3 engineers review every order)