Aluminum CNC Machining Services

Manufacturer of custom aluminum parts

Aluminum is most used materials in CNC machining, thanks to its excellent strength-to-weight ratio, corrosion resistance, and ease of machinability.

At RJC, we offer custom aluminum parts from rapid prototyping, low volume production, and mass production.

Our CNC Aluminum Machining Capabilities

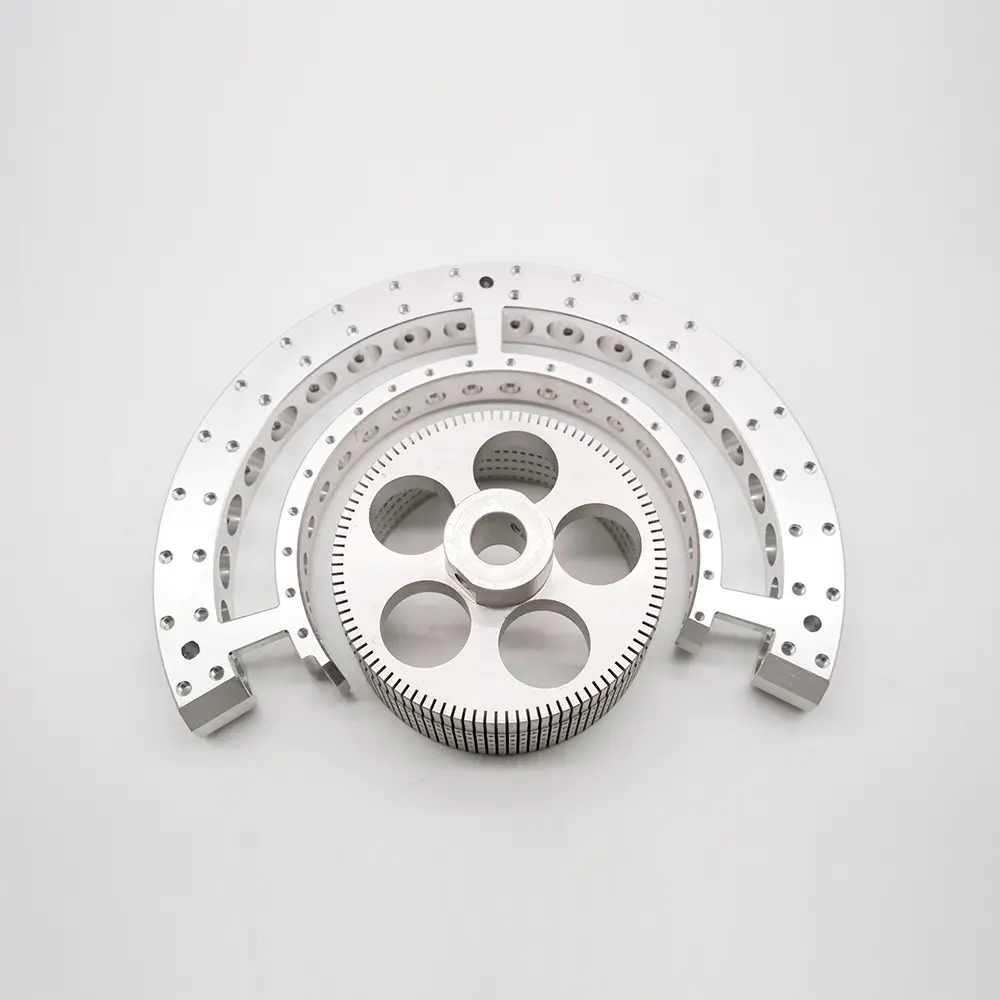

We offer comprehensive CNC machining services for aluminum, ensuring tight tolerances and smooth surface finishes:

- Processes: CNC milling, CNC turning, 5 Axis CNC machining

- Tolerance: Up to ±0.005mm for critical dimensions

- Part Size: Up to 1200 × 800 × 500mm

- Volume: 1 to 10,000+ parts

- Lead Time: 3–5 days for prototypes; 7–12 days for production

All parts are inspected using precision metrology tools and supported by engineer-led design for manufacturability (DFM) feedback.

Advantages of aluminum

Industries We Serve

Suitable for all industries requiring precision aluminum parts.

Common Aluminum Grades We Work With

| Alloy | Main Alloying Elements | Key Features | Common Applications |

|---|---|---|---|

| 6061-T6 | Magnesium (Mg) + Silicon (Si) | Balanced strength, corrosion resistance, anodizing friendly | Enclosures, brackets, structural parts |

| 7075-T6 | Zinc (Zn) + Magnesium (Mg) + Copper (Cu) | Very high strength, aerospace-grade | Robotics, UAVs, racing parts |

| 2024 | Copper (Cu) + Magnesium (Mg) | High fatigue resistance | Aerospace components, mounts |

| 5052 | Magnesium (Mg) | Excellent corrosion resistance, weldable | Marine parts, electronic casings |

| MIC-6 | Aluminum (Al) + Silicon (Si) + Copper (Cu) + Magnesium (Mg) | Stable, stress-relieved cast plate | Jigs, fixtures, plates |

Need help selecting the right alloy? Contact our engineers for suggestions.

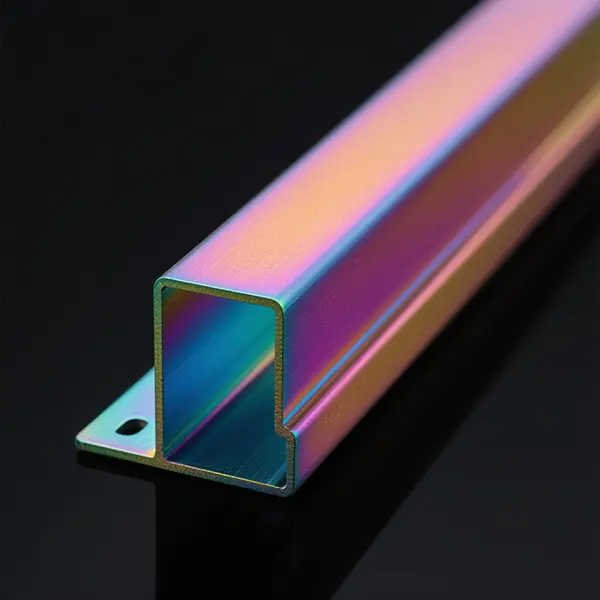

Surface Finishing For Aluminum Parts

Explore more finishing options on our surface finishing services page.

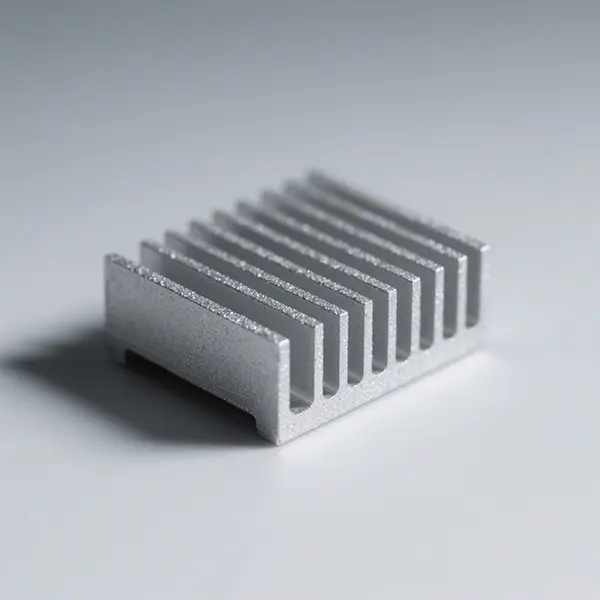

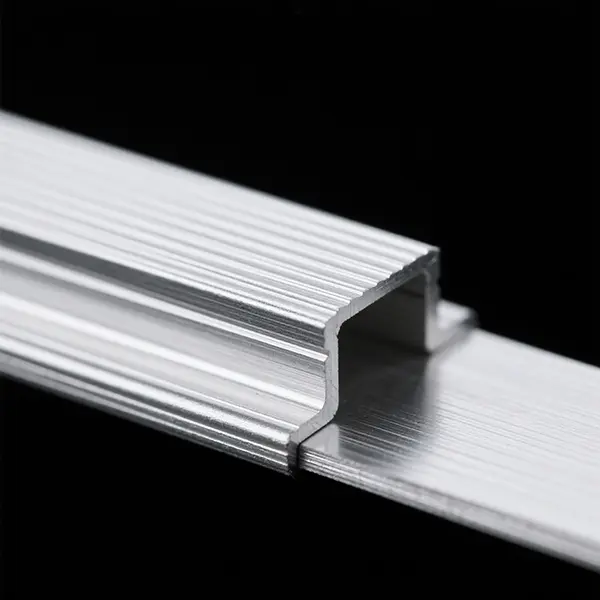

Aluminum CNC Parts We Manufacture

Why choose RJC for Aluminum CNC Machining?

- CNC machining manufacturer with over 20 years of experience

- ISO 9001 certified facility

- In-house quality control with full inspection reports

- Fast lead time — 3 to 5 days for prototypes

- Engineer-reviewed DFM suggestions

- NDA protection for every customer

We understand global buyer needs — from quality expectations to shipping and customs — and help you receive reliable parts on time.