CNC Milling Service

Reliable on-demand CNC milling services for rapid prototypes and production parts.

Get top-notch custom milled parts from various high-quality metals and plastics at competitive prices.

RJCmold offers cost-effective milling service whether you need a single part, batch of prototypes, or full production order.

High Quality Rapid CNC Milling Service

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals. With machined production parts, you can also get more competitive pricing at higher quantities in addition to first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and chromate plating.

We guarantee your CNC milling projects will be handled smoothly by our in-house CNC machining department and supplier network. As a result, you can focus on bringing your product to market. If you need a reliable CNC milling company, RJCmold will never let you down!

RJCmold CNC Has Multi-Axis Milling Capabilities to form Mission-Critical Components

The demands and quality standards of CNC-milled components for aerospace, defense and other specialized industries have become increasingly stringent as technologies advance.RJCmold has experience working closely with top OEMs from a variety of industries to ensure we adhere to the highest quality standards when machining specialty metals.

Our skilled manufacturers utilize modern equipment and S9100 REV D & ISO9001:2015-Certified manufacturing techniques to form specialized, reliable complex components. We utilize 3-axis, 4-axis and 5-axis machining centers and innovative CAM programming to form products up to 40 inches in length that hold up to your application requirements.

Advantages Of CNC Milling Services For Product Developers

CNC Milling services at RJC have many advantages for product development that can make it the ideal solution not only for rapid prototyping but also for volume production. Here’s what you can get.

- Quick removal of large amounts of metal as well as engineering-grade plastic resins

- Highly accurate and repeatable

- Excellent for making complex geometries

- Versatile

- Suitable for many different kinds of substrates

- Scalable volumes from one to 100,000

- Low investment in tooling and preparation cost

- Fast turnaround

- Parts are full-strength and can be put into service immediately

- Excellent surface finishes

- Easily customized

Get Your CNC Machining Project Started Today

With a range of options for CNC finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements. Contact us today for a free quote!

Custom CNC Machining Materials

| Aluminum | Bronze/Brass | Copper | Plastics | Steel / Titanium / Zinc |

|---|---|---|---|---|

| Aluminum 5052 | Brass C360 | EPT Copper C110 | ABS | Alloy Steel 4130, 4140 |

| Aluminum 7075 & 7075-T6 | Brass 260 | Copper 101 | Acetal [Delrin] | ASTM A36 |

| Aluminum 6063-T5 | C932 M07 Bearing Bronze | Acrylic | Stainless Steel 15-5, 17-4, 18-8, 303 | |

| Aluminum 7050-T7451 | G-10 Garolite | Stainless Steel 303, 304, 316/316L | ||

| Aluminum MIC-6 | Nylon 6/6 | Stainless Steel 416, 420 | ||

| Aluminum 6061-T6 | PEEK | Steel, Low Carbon | ||

| Aluminum 2024-T3 | Polycarbonate | Steel A36 | ||

| PTFE [Teflon] | Titanium Grade 2, Titanium 6Al-4V, Zinc Sheet Alloy 500 | |||

| Polypropylene | ||||

| Ultra-High Molecular Weight Polyethylene |

Additional alloys and tempers are available upon request. We can source to your project specifications. If you do not see your alloy or material listed on our platform, please select “Other” and write in that specific material.

Custom Sourced Materials: A variety of custom CNC milled parts, including metal and plastic, options are available for an instant online quote. If you do not see the material stock you are looking for, please choose “Other” under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

CNC Milling Tolerances

RJCmold offers a range of CNC machining tolerances to suit your unique design requirements, including GD&T callouts. Based on your part’s geometry and chosen material, we can accommodate standard thread sizes, machine custom treads, and reach tolerances of up to ±0.001”. Our standard tolerances for CNC milled metals are ISO 2768-m and ISO 2768-c for plastics.

| Description | General Tolerance or Standard |

|---|---|

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult RJCmold’s Manufacturing Standards. |

| Precision Tolerances | RJCmold can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | RJCmold can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Surface Finishes for CNC Milling

Gain access to quality surface finishing for custom CNC milling parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

What is CNC Milling?

The Basics Of CNC Mills

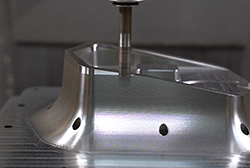

CNC mills are automated cutting machines using a rotating spindle-head to cut away unwanted material. CNC milling machines come in a variety of sizes and different axis configurations. They are mainly utilized to cut harder metals but can work with workpiece materials ranging from plastic and aluminum to stainless steel and titanium.

How CNC Milling Works

CNC mills excel at profile cutting harder materials. Like all CNC machines, a CNC mill is controlled with G-Code created through CAM software. The Gg-Code instructs the machine where to move the tool head, how fast to spin the tool, how deep to cut, how to move the workpiece, and other factors relating to speed, feed rate, and coordination. The G-Code complexity depends on how many axes the milling machine has.

Mills can still be used for profile cutting of softer materials, but are not as cost-effective for that use as CNC routers. The main difference between these machines is that with a CNC router the workpiece remains stationary while the router cutting head is directed around the piece, while a CNC mill may move both tool head and workpiece. CNC mills are mainly used in industrial manufacturing, while CNC routing is more common for lower output manufacturing like woodworking.

Applications of CNC Milling

Rapid Tooling

Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production makes CNC a great option for prototyping.

End-Use Production

High-quality finish, vast material options and precise tolerances have made CNC a favorable technology for end-use parts.

Typical CNC Milling Parts That We Offer

CNC milling is very flexible way to create prototype or manufacture high volume end-used parts. Plus wide ranges of milling materials are available, it fit most types of projects. Our CNC experts know how to cut your parts fast to reduce the cost, and how to mill the complex geometry and tight tolerence custom designed parts in different materials. We have delivered million+ high quality CNC parts to our worldwide customers.

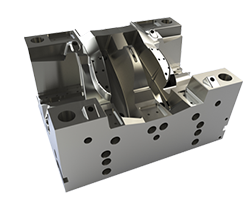

Mold Components

CNC milling is playing an important role in mold making. Mold cavities, mold bases, sliders, lifter, and other mold components can be milled.

Plastic and Metal Valves

Parts like valves, engine house which require complex geometry and tight tolerance. We can make such part with our 5 axis CNC milling.

Medical Parts

CNC milled implants in medical-grade material. We are familiar with bone fracture plate and other components which can be used in surgery.

Automotive Prototypes

Besides mechanical parts such as aluminum engine house and covers, steel shafts, We also good at the parts with tiny features as light guides and reflectors.

Machine Components

This is a rotating cutter for a mask machines. It is important to make it sharp and in the mean time to keep the condentricity under +/-0.01mm.

CNC Milled Adapters

CNC milled aluminum adapters, tight tolerance for dimension, and angles of the holes, with alodine finish.

Design Guidelines

Our basic guidelines for CNC milling include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Why Choose RJC for CNC Machining Services?

RJC CNC machining services are second to none. Here are some of the advantages we offer to every client on every project, regardless of size.

✓ Industry-Leading CNC Manufacturing Equipment and Materials

Our imported 5-axis CNC machining centers make turned and milled parts from a wide range of plastic, and metal alloy materials – such as aluminum, brass, nickel, and steel, both mild and stainless steel. We use industry-leading software.

✓ A Proven Track Record

We can easily talk about our team’s experience and performance, but one of the best ways to show the superiority of our CNC machining services is to let our work speak for itself. Scroll down to our “See Our Past Projects” section to learn more about some of our thousands of success stories we’ve had with partners. We offer our services for the whole process – from the initial stages of product design, helping with material selection, to the point of manufacturing the first prototypes, to the final production run.

✓ Comprehensive Raw Material Testing and Verification

Our uncompromising material testing processes are a big reason why our CNC machining services are a cut above. All incoming raw materials are subject to chemical and physical analysis using advanced scientific equipment. No one else offers this level of material quality control, providing you with peace of mind along with Certificates of Compliance upon request. And of course in-process inspection ensures that each part is produced exactly to your design specifications.

✓ A Full Suite of Finishing Services

Many CNC machined parts require some form of post-finishing before they are ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching to painting, we offer every surface finish you need to make a great finished part.

RJC CNC Milling Service FAQ

1. Why use CNC milling?

Besides CNC turning, CNC milling is one of the most popular custom manufacturing processes. CNC milling is used for the majority of machined parts because it can handle a wide variety of irregular geometries. It is also an efficient means of mass production once the setup is complete

2. What kind of equipment do you use?

RJC”s facilities contain high-end 3-axis, 4-axis and 5-axis machining centers.

3. Can I combine milling with other processes?

Yes. We can use a CNC machine to mill details, features and text onto parts made using other processes like casting and 3D printing.

Request Your Free CNC Milling Quote Today

Our improved algorithm decreases CNC Milling quotation times by up to 90%. Most quotes are delivered within 24 hrs. and usually in much less time, depending on project details.

Your customer support partner will contact you directly about your CNC Milling quote to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have about your options.