Injection Molding Service

Injection molding services for plastic parts with fast turnaround, tight tolerances, and support for complex geometries.

Get custom plastic parts in as few as five business days, certified to ISO 9001, ISO 13485, and IATF 16949. Free DFM report & moldflow simulation available.

Custom Injection Molding Services

RJC supports prototype, low-volume, and mass-production injection molding with aluminum or steel tools. Our engineering team provides DFM optimization and moldflow simulation to ensure your custom parts are production-ready.

Our facility is equipped with medium-sized (100-500T) machines, 500T-650T machines, and 1000T large machines, enabling us to handle diverse part sizes and complexities. All molds are developed and manufactured in-house.

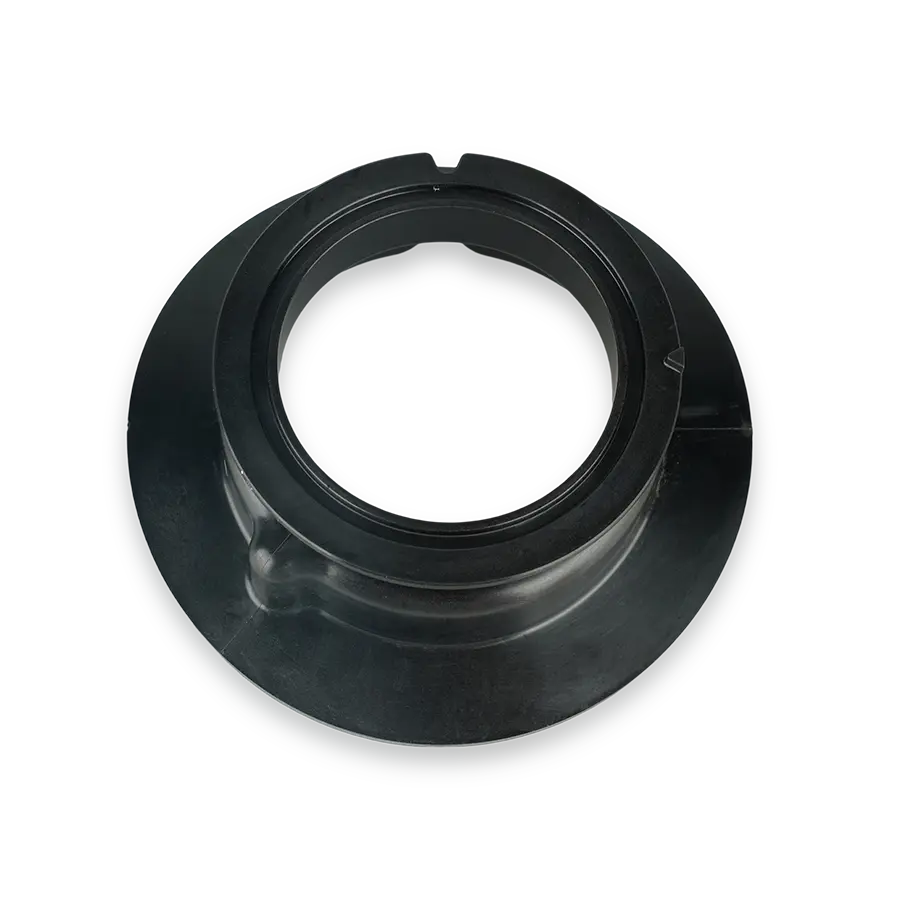

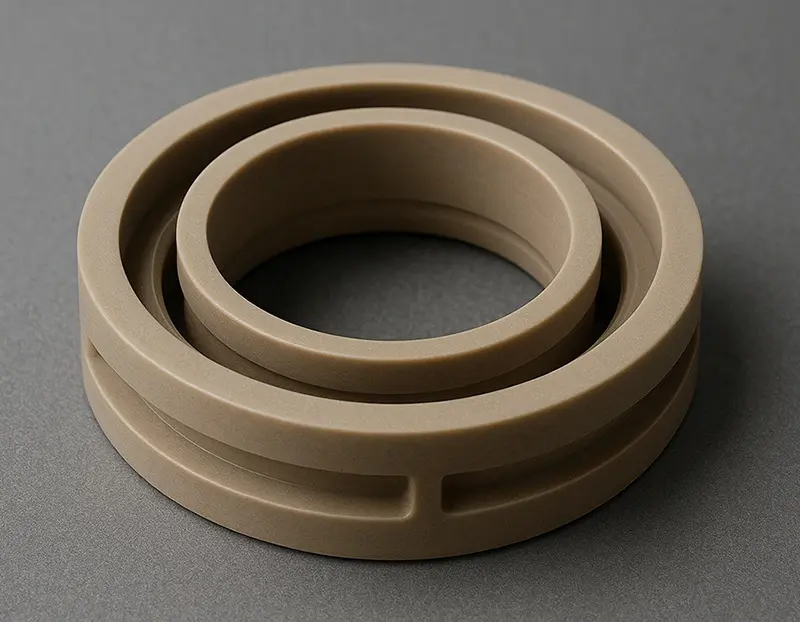

Injection Molding Parts Samples

RJCmold’s engineering design team can take your project from concept to design by supporting customers’ designs for manufacturability and mold flow analysis.

Custom Injection Molding Process

Simply upload your CAD files to receive a free DFM report and moldflow analysis.

Upload CAD / drawings

Free DFM review

Mold design

Mold manufacturing

T1 sampling

Mass production

Quality inspection

Global shipping

Injection molding process parameters

We offer flexible injection molding solutions, capable of handling everything from rapid prototyping to large-scale production. With a focus on precision and fast lead times, we ensure plastic parts that meet your custom requirements.

| Category | Details |

|---|---|

| Lead Time | Starts at 5 business days; most orders within 15 days. |

| Machines & Mold Types | 50T – 1100T machines; single/multi-cavity & family molds; steel & aluminum molds. |

| Part Size Range | 5 × 5 × 5 mm to 1200 × 1000 × 500 mm |

| Tolerances & Precision | Mold cavity tolerance ±0.02 mm; part repeatability ±0.1 mm. |

| Wall Thickness & Features | 0.5 mm – 5 mm walls; 0.5° – 2° draft; undercuts, ribs, gussets, bosses. |

| Production Volumes | Prototype to mass production (up to 100,000+ cycles). |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, assembly. |

Materials for Injection Molding

These are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.

ABS

Features & Uses: Tough, impact-resistant, easy to machine and glue; great for prototypes, housings, fixtures, consumer products.

Surface Finish: Matte bead blast, texturing, painting/printing.

Our Injection Molding Services for Various Industries

RJCmold works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom injection molding services helps more and more manufacturers bring their idea to products.

22+

Over 22 Years of Experience in Injection Molding

3000+

Trusted by 3,000+ Enterprise Customers Worldwide

10000+

Completed 10,000+ Custom Injection Molding Projects

20000+

Processed 20,000+ Design Drawings for Manufacturing

Injection Molding Service FAQs

Find answers to common questions about material selection, quality control, lead times, cost optimization, and design considerations. This section helps you make informed decisions and ensures a smooth manufacturing process.

We offer a wide range of materials, including ABS, PC, PP, PA, POM, and high-performance resins like PEEK and PPS. The right choice depends on factors like mechanical strength, heat resistance, and chemical exposure. If you’re unsure, our team can recommend the best material based on your application.

We maintain tight tolerances—mold cavity tolerance of ±0.02 mm and part repeatability of ±0.1 mm. Our process includes strict quality control checks, including first-article inspection, in-process monitoring, and final testing to ensure every batch meets specifications.

Lead times start at 5 business days, with most orders completed within 15 days. Factors like mold complexity and production volume can affect delivery time, but we prioritize efficiency without compromising quality.

We optimize costs by offering both steel and aluminum molds, single/multi-cavity options, and family molds to maximize efficiency. We also provide design feedback to help reduce unnecessary complexity and minimize production expenses.

- Wall thickness between 0.5 mm – 5 mm for optimal strength

- Draft angles of 0.5° – 2° to aid mold release

- Avoiding sharp corners to reduce stress points

If needed, our engineers can assist in refining your design for better performance and cost-efficiency.

Yes, we provide mold texturing, pad printing, laser engraving, threaded inserts, and assembly services to deliver finished parts ready for use.

Yes, we support everything from low-volume production to mass production, accommodating orders up to 100,000+ cycles.

At Rjcmold, we design and create precise custom injection molds from high-quality materials. Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing. Every plastic injection molding we fabricate meets international standards. From one-off projects to small batches and production tooling, we provide durable and reliable mold tools.

| Mold Class | Purpose | Shot Life | Tolerance | Lead Time |

|---|---|---|---|---|

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.05mm | 10-18 days |

| Class 104 | Low-volume Production | Under 100000 cycles | ± 0.05mm | 2-3 weeks |

| Class 103 | Low-volume Production | Under 500000 cycles | ± 0.05mm | 2-3 weeks |

| Class 102 | Medium-volume Production | Under 1000000 cycles | ± 0.05mm | 2-3 weeks |

| Class 101 | High-volume Production | Over 1000000 cycles | ± 0.02mm | 3-4 weeks |

| Name | Description |

|---|---|

| Glossy | Using a diamond buffing process, we can achieve shiny and glossy surfaces on injection molded parts. |

| Semi-glossy | Use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture |

| Matte | Use grit sanding stones to produce parts with a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. |

| Textured | Use grit, dry glass beads, or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or a dull finish. |

Related Posts

Understanding of materials, applications and processes in the injection molding industry.