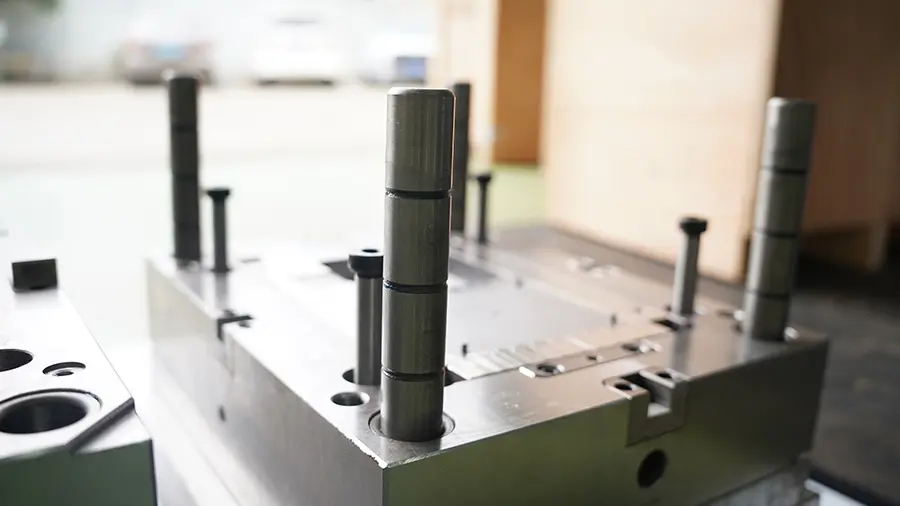

An experienced plastic injection molding company

Our company is able to offer you low volume production tools using different technologies and fast delivery solutions to meet your needs.

Tools: SMC/BMC Molds, Multi Cavity Molds, Over-Moulding Tools, Aluminum die casting Molds

Capabilities: Injection Machine– 100+ sets, 140,0000+ parts made per month, Tool as fast as 3 weeks, Part as fast as 7 days

Benefits of our injection molding service

Using an injection molder to fulfill large orders provides an extensive range of advantages that can help us meet any project or demand you may have. These include:

Custom plastic parts manufacturer

We’re oI have more than 20 years of experience in molding plastic parts. Plus, our injection molding facility is equipped with the latest injection molding machines.

All your custom plastic part needs, we’ll guide you through the process – from concept to completion.

Why Choose RJCmold plastic injection mold Design and Manufacturing Service?

As a custom plastic injection molding service company in China, RJCmold offers precision and cheap plastic injection molding parts for low volume rapid prototyping.

RJCmold can offer Rapid Prototype parts with our plastic injection mold service and manufacturing services. For Rapid Tooling and low volume production, we develop a universal mold base in various sizes, feasible of running side actions, this will reduce the standard tooling cost and lead time by 30%.

Related Posts

Understanding of materials, applications and processes in the injection molding industry.

Injection Mold Tooling Cost Calculator (2026): 5-Min Estimate

An injection mold tooling cost calculator estimates your price of the mold and scores the largest cost factors, including the tool material, the number of cavities, the complexity of [...]

Recommended Materials for Robot Enclosures

For mass-produced consumer robots and most service robots, PC/ABS should be the primary material choice. Depending on operating conditions, ABS, glass-fiber–reinforced PA (PA+GF), or PBT can then be evaluated [...]

How to Select the Right Plastic Material Based on Application Scenarios

Selecting a plastic material is a systematic decision-making process that requires balancing multiple factors. Below is a clear and practical framework to help you choose the most suitable plastic [...]