Custom Aerospace parts

Leading manufacturers of aerospace components trust us to preserve the integrity of their designs and quite literally get their projects off of the ground on a schedule they can count on. We understand that the components we produce are on the critical path for prototype evaluation and pre-production testing for various applications in the aerospace industry, including interior aircraft components, drone components, wiring organization components, and many others.

We communicate very closely with our clients and their procurement teams throughout the production process for their design, involving an in-house subject matter expert at every stage to produce components to exact design specifications on time and budget.

Leading aerospace parts manufacturers believe that we can preserve the integrity of their designs and start their projects on schedule.

We learned that the components we produce are on the critical path to prototype evaluation and pre-production testing for various applications in the aerospace industry, including aircraft interior company, UAV components, wiring organization components, and many others.

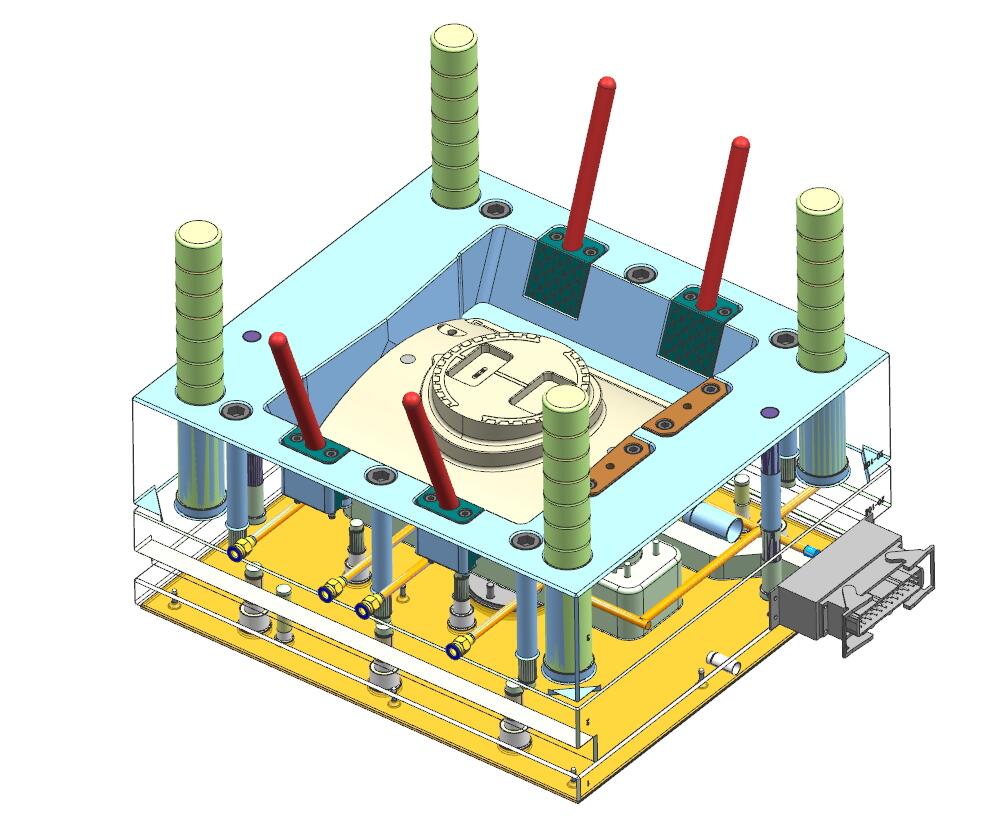

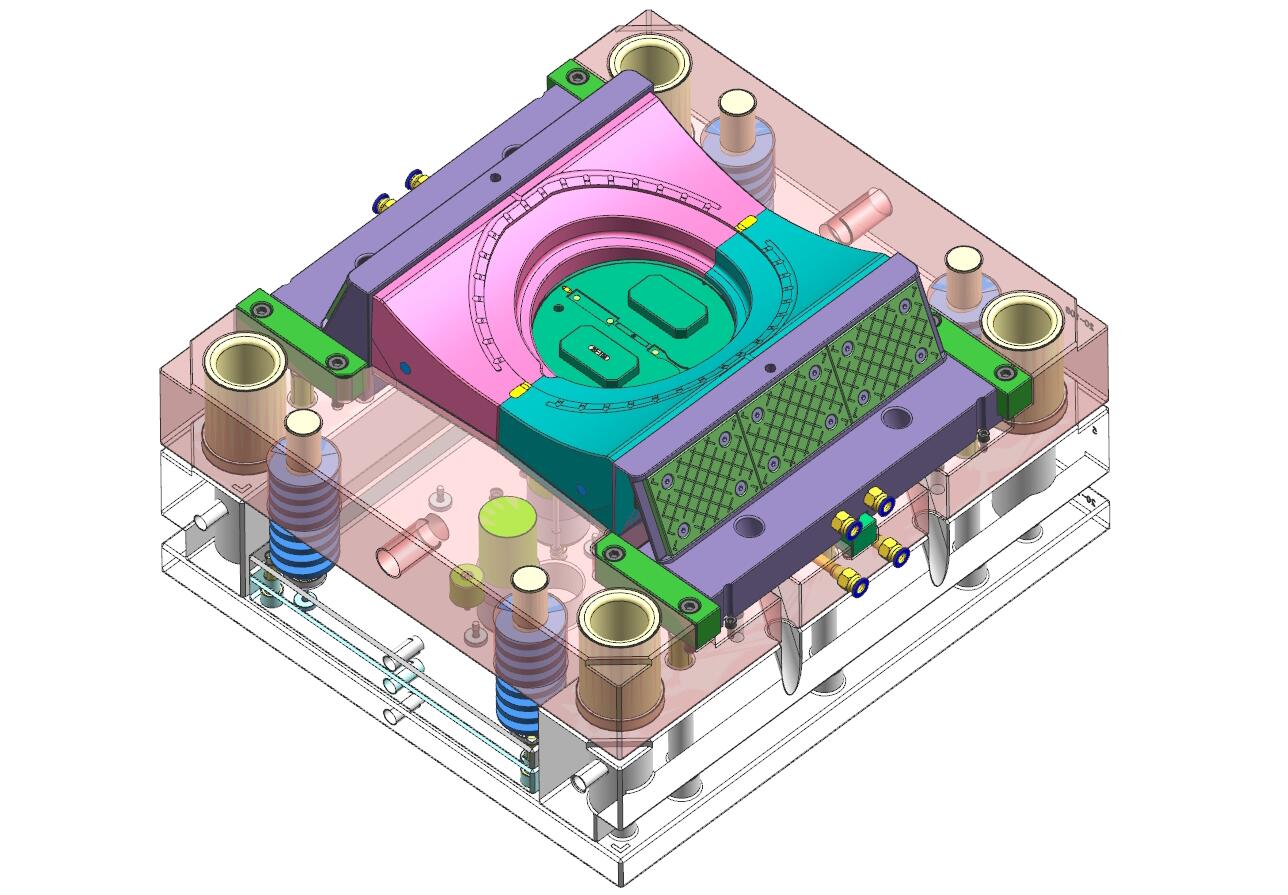

Aerospace Component Mould Design and Products Show

Mold 3D Drawings

Mold Drawings

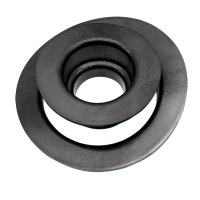

Aero Fitting Tooling

Aero Fitting

Custom hardware supply solutions that meet any demand

Designing aerospace and defense components is an inherently high-risk endeavor. This puts greater stress on the early development stages when materials and manufacturing processes are being tested and validated. To combat this, product engineers turn to RJCMOLD to iterate designs more quickly, prototype in final materials, and manufacture complex geometries. Our automated manufacturing services can be leveraged throughout the product life cycle, from early prototyping and design validation to hot-fire testing and launch.

Products Designed to Meet Strict Safety Standards

We are committed to ensuring that all aerospace prototype and production parts we deliver meet your specific requirements, which is why we hold quality standards for ISO 9001:2015, as well as National Aerospace & Defense Contractors Accreditation Program (Nadcap), WBENC (National Women’s Business Enterprise Certification) and WOSB (Woman-Owned Small Business).

- ISO 9001:2015: For aerospace and defense manufacturing of prototype and production parts utilizing additive manufacturing, CNC machining, and injection molding

- Nadcap: For manufacturing in conformance with non-conventional machining requirements

- WBENC and WOSB: For successfully meeting WBENC’s standards for a Women’s Business Enterprise as a woman-owned, operated, and controlled business

With ISO 9001:2015 certifications, we can adhere to stringent aerospace and defense quality regulations to make components for aircraft, satellites, and unmanned aerial vehicles (UAVs).

Custom Aerospace Injection Molding With RJCMOLD

Our strength is in saying “yes” – we help our customers make parts that others can’t make. Aerospace companies large and small have found value in our highly customized services including:

- Thorough design for manufacturing (DFM) review of the part design including a tool design review of key elements: parting line, ejector pin, and gate

- FAIR Production Reporting

- Small and large project support

- Global material selection – ENGR grade material selections with carbon fiber fillers.

- Rapid Prototype Tooling, Bridge Tooling available

- Urethane casting and 3d printing services are also available for testing and prototyping

- Multiple Process Support (overmolding, assembly, custom inserts, heat stake inserts, custom finishes, ultrasonic welding, EMI/RFI shielding)

- Material test samples

- Optimized process development (scientific molding)

- Mold flow generation and review

- Tight tolerance achievements for specific characteristics

- US domestic and overseas options available

- Post-mold machining operations leveraging our CNC factory

We also help you navigate the complexities of the injection molding process. Our skilled team of engineers:

- Understands your end-use (prototype, saleable, low to high volume) and helps identify the right manufacturing solution

- Guides you through multiple tool trials, including managing design iterations

For your free quote and design-for-manufacturability feedback, please Send your CAD file. We want to earn your business. If you get a lower injection molding quote, send it to us and we will try to beat it.

Aerospace Plastic Injection Molding & Other Capabilities

To create the parts necessary for the aerospace industry, we complement our injection molding capabilities with other design technologies. Our CNC milling, cnc turning and live tool services offer precise design specs and appearance for your device in the aerospace industry. We have 20 years of service experience and have deployed all of our services, including 3D printing and urethane casting to assist in aerospace plastic injection molding as part of this evolving and progressive process. We produce highly intricate mission critical parts utilizing high temperature and high strength thermoplastic resins, including glass and carbon fiber reinforced compounds, designed to function in critical and harsh environments. Sample projects include:

- Armrests

- Panels, housings and lenses

- Transit, storage and impact protection

- Extreme operating environment equipment

- Housings

- Fuse Covers

- Metal replacement components

- Turbine blade holders

Further, our program management expertise facilitates design, development, validation and qualification. We strictly adhere to specifications and lot and batch traceability and are ISO 9001:2015 and ITAR registered.

Manufacturing Aerospace Components

Parts manufacturing for the aerospace and defense industry requires precise, responsive product development and production. Whether you need short-run, low-volume, or large-volume production with assembly, we ensure your project meets all industry standards and requirements.

We have different manufacturing technologies to support the material and volume needs for aerospace and defense components, like Carbon DLS additive manufacturing, 5-axis CNC machining of metals and plastics, and tooling for aerospace injection molding. We understand that manufacturing Aerospace components means that we need to manage and make all parts we produce in-house in our USA facilities outside ShenZhen. We do more than simply supply parts, we are an essential part of your team.