Definition and Production Process of Injection Molding

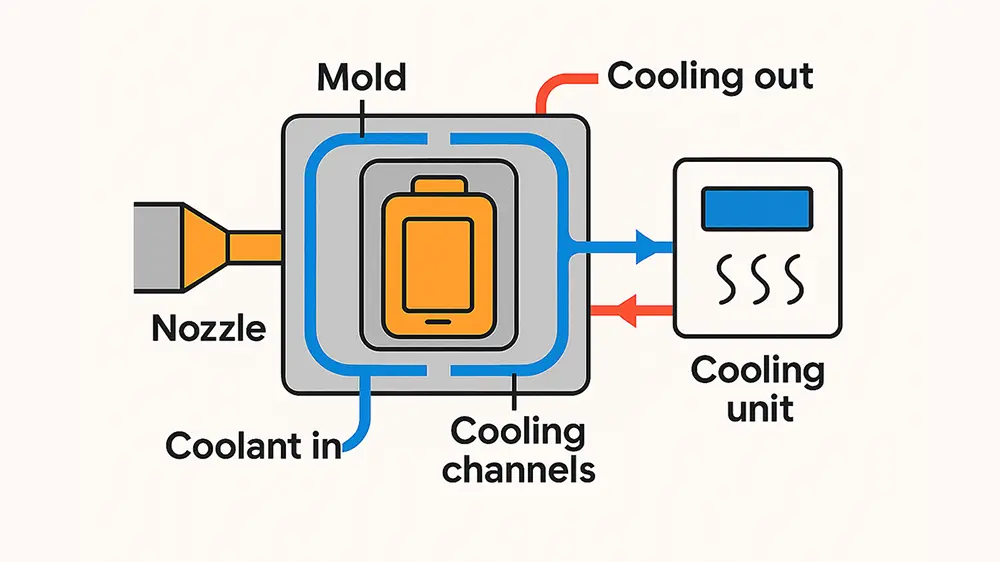

Injection molding is a forming process where molten plastic material is injected into a closed mold cavity. After cooling and solidification, a plastic product matching the cavity shape is obtained.

The production process: Material feeding (including drying: Since moisture or volatile substances in raw materials can cause bubble defects, materials are dried at 80-120°C for 2-4 hours prior to injection. To enhance equipment utilization, many manufacturers have transitioned from drying materials in injection molding machines to using centralized drying systems that automatically deliver dried materials to corresponding machines), melting, injection, cooling, demolding, part removal, and mold closing. Throughout the plastic injection molding process, cooling time is a critical control point. How does excessively long or short cooling time impact product quality?

Impact of Cooling Time on Injection Quality and Efficiency

Within the entire injection cycle from mold closing to the next mold closing, the injection holding pressure phase accounts for 10%-20% of the time, the cooling stage for 60%-80%, the demolding phase for 5%-15%, and the part removal and mold closing phase for 5%-10%.

The cooling process involves the mold cooling system dissipating the melt’s heat, transforming the plastic from a fluid state to a glassy or crystalline state. This solidification forms the desired shape and develops mechanical properties. As the cooling phase occupies over half of the injection cycle, it significantly impacts product dimensional accuracy, surface quality, and mechanical properties. It also affects production efficiency, necessitating the identification of an optimal control point between high production speed and thorough cooling.

I. Effects of Insufficient Cooling

1. Product Appearance Defects

Insufficient cooling time prevents complete solidification of the melt, causing sticking during demolding and resulting in surface defects such as scratches, streaks, ripples, uneven gloss, or haze on transparent parts.

For example, a Shenzhen-based company producing transparent covers for the European market using PC material. During the injection molding process of the components, when the cooling time was set at 18.8 seconds, a fog-like appearance appeared on the surface of the transparent body. Analysis indicated insufficient cooling time for this complex product. After adjusting the cooling time to 19.8 seconds, the produced parts achieved good transparency and met quality standards.

2. Dimensional Accuracy Deviation

Insufficient cooling time prevents complete cooling and shrinkage, causing continued deformation after demolding. This leads to dimensional deviations, sink marks, warping, and other quality issues.

3. Reduced Mechanical Properties

Short cooling times result in uneven crystallization within plastics (e.g., PP, PA) or disordered molecular chain orientation. This diminishes tensile strength, impact resistance, and heat resistance, increasing fragility.

4. Difficult Demolding and Flash Defects

Insufficient strength during demolding of incompletely solidified melt may cause cracking or whitening. Simultaneously, incomplete cooling and setting of the melt allows it to overflow through mold gaps under injection pressure, forming flash.

II. Effects of Excessive Cooling Time

1. Mold Adhesion and Other Quality Defects

Materials like PVC and TPU may adhere to molds due to molecular adsorption during prolonged contact with low-temperature molds. Plastic surfaces at low temperatures are prone to defects like dull gloss and cracks.

For instance, a Shenzhen-based company producing PVC interior sealing strips for the South American market (wall thickness: 1.8mm, mold temperature: 28°C) experienced sticking at a set cooling time of 15 seconds. Analysis revealed excessive cooling duration. After adjusting the cooling time to 13 seconds, sticking ceased during continued production.

2. Increased Production Consumption

Prolonged operation of the mold cooling system consumes more cooling water or other refrigeration energy, increasing production costs and consumption.

3. Reduced production efficiency and wasted capacity

From the perspective of the cycle time, during the cooling phase where the molten material solidifies after being injected into the mold, cooling time accounts for approximately 60%-80% of the entire injection molding cycle. If cooling time constitutes 60% of the injection cycle, an additional 6 seconds per mold would reduce production efficiency by nearly 6%.

III. Factors Affecting Cooling Time

1. Cooling System

Common cooling media include water-cooled, oil-cooled, and air-cooled systems. Embedded cooling channels are designed as straight, curved, or mesh patterns according to product geometry. To achieve more efficient cooling and reduce cooling time, complex cooling systems in mold cavities are designed with conformal cooling channels. This allows the cooling medium to directly contact the product for cooling, ensuring uniform cooling and reducing quality defects such as warping and deformation. This approach can reduce cooling time by 30-50%, improving cooling efficiency. During the cooling stage of injection molding, mold temperature must be adjusted based on plastic material type—e.g., 40–60°C for ABS, 80–120°C for PC.

2. Plastic Material Properties

Different plastics have varying melting points. Crystalline materials like PP, PE, and PA require longer cooling times to ensure complete crystallization—e.g., PP melts at approximately 167°C. Non-crystalline materials such as ABS, PC, and PMMA have lower melting points and faster cooling times—e.g., ABS melts at about 105°C, while PC melts at 150°C. In practice, injection molding temperatures should exceed the melting point by 10-50°C. For example, PP injection temperatures are typically set between 180-220°C.

The thermal conductivity of plastic materials also affects cooling time. Materials with high thermal conductivity transfer heat to the mold more rapidly, thereby shortening the cooling phase; materials with low thermal conductivity cool more slowly and require longer curing times to ensure dimensional stability and surface quality.

3. Product Structure

Products with more complex shapes and greater wall thickness (or reinforcing ribs) require relatively longer cooling times. Conversely, products with thin walls and simple structures have relatively shorter cooling times.

Summary

In injection molding, cooling time is both a critical parameter affecting product quality and a key variable determining production efficiency. Only by thoroughly understanding the relationship between material properties, product structure, and the mold cooling system design can the optimal cooling time be determined to enhance cooling performance, achieving the unity of stable quality and high-efficiency production.