In injection molding, the largest part of the manufacturing cycle is cooling. The cooling phase of the manufacturing cycle is about 60-70 percent of the cycle, and reducing this by a small amount will allow your production operations to produce more products in less time.

To ensure that a minimum cooling time is achievable, you must first have the correct injection mold cooling system design and the best cooling method.

Cooling method of injection mold

There are two standard methods for cooling systems: air cooling or water cooling.

• Air-cooled molds are not often used because they take a long time to reduce the heat in the injection mold, dissipating through heat transfer to the surrounding air. If the surrounding environment of the injection molding machine and the mold itself is kept cold, it will increase the heat released into the air. It may also require additional operating costs to cool the space.

• Fluid cooling molds are the primary source of cooling, with glycol and water being the most commonly used fluid mixtures. Water provides cooling as it flows through the mold, taking heat away from the mold. Glycol prevents corrosion from forming in the mold’s cooling pipe and helps the mold maintain a stable temperature during manufacturing.

Cooling system design

When designing a new injection mold cooling system, several issues need to be addressed to maximize cooling and reduce cycle time:

• All cooling channels in the mold must be close to the thickest part being formed.

• If the cooling channels in the mold are greater than 8 mm, they should remain the same diameter in the mold.

• Do not have a large cooling channel inside the mold, it is better to add several smaller channels to evenly distribute the coolant.

• When designing molds, use conductive materials to improve cooling. This will help heat transfer from the part as it cools in the mold.

• Make sure both halves of the injection mold are fully cooled. Only cooling half or part of the injection mold increases the chance of partial warping as it cools.

Air cooling system

The use of an air cooling system involves an evaporator to remove heat from the injection system. An air-cooled condenser is then used to remove the heat from the evaporator. What you can expect from the air cooling system is an intake fan to direct the cooler air to the mold, and an exhaust fan to remove the hot air from the mold. The air cooling system transfers heat from the flowing water in the injection molding machine assembly line to the air around the assembly line in the cooler. Because air doesn’t transmit heat the way water does, this fan-cooled air typically consumes 10 percent more electricity.

An air cooling system will discharge hot air into your plant. Therefore, it is best to install an air-cooled refrigerator outside the building or where there is no air conditioning. As airflow increases, the air cooling system becomes dusty and must be regularly maintained and cleaned to maintain a high level of performance. In terms of space, an air-cooled chiller can technically occupy any open or flat space, requiring less total space than a water-cooled unit requiring a cooling tower.

Water cooling system

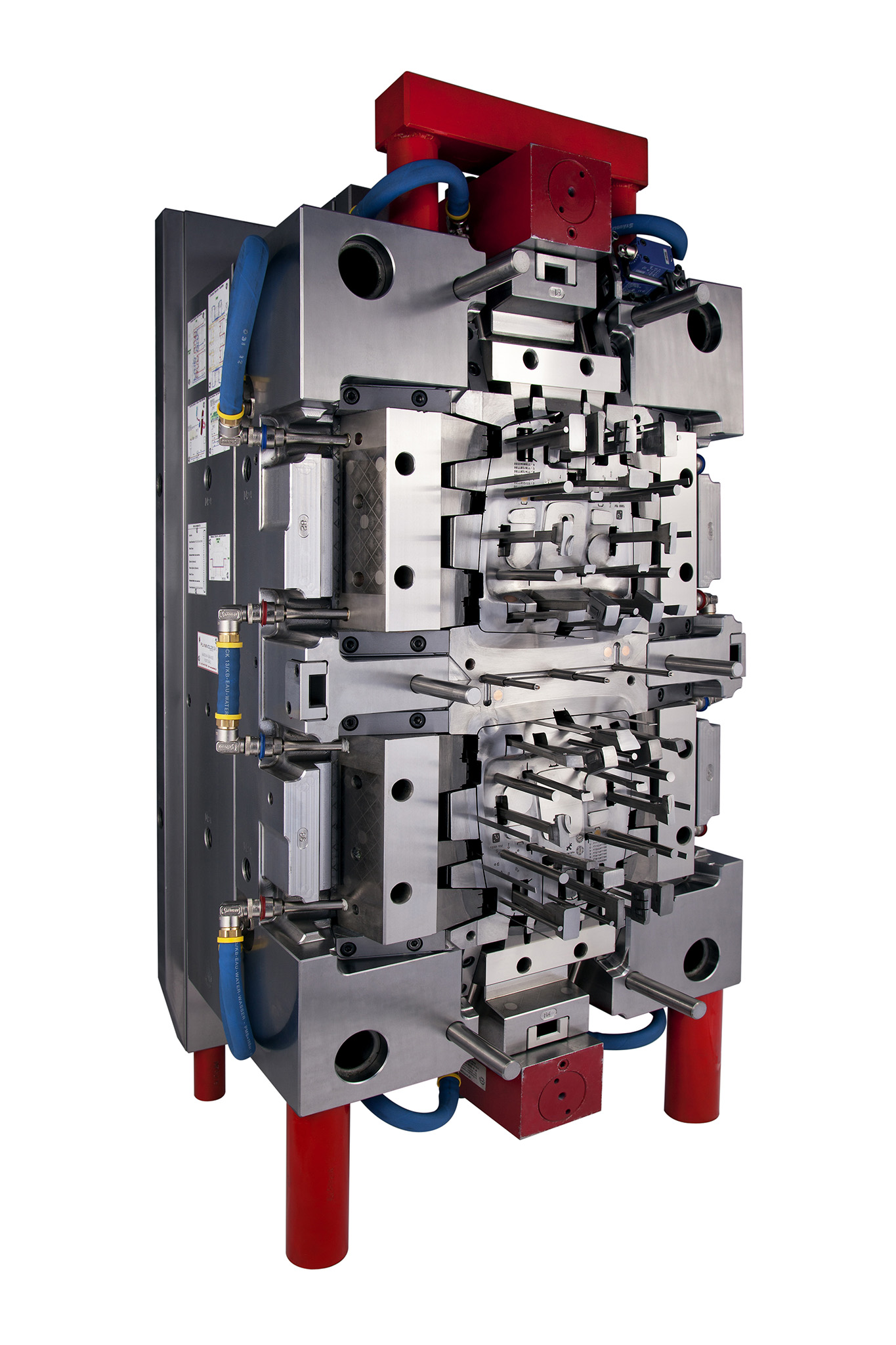

A water cooling system, also known as a hot press, works by transferring frozen water through pipes running through the mold cavity and outside the runner gate. These waterlines will be closest to the outside of the molded product surface to ensure uniform cooling and prevent warping of the product surface. The water in the cooling line is chemically treated to prevent mold and bacteria from growing or contaminating the line.

The two types of flow that pass through these waterlines are laminar and turbulent, and they describe the way water flows. Laminar flow describes the flow of water through a straight line, so the water in the center of the flow does not touch the inner surface of the line. Turbulent cooling is more efficient because more surface area of water is in contact with the heated cavity.

The water cooling system leaves condensate outside the mold. This is because the temperature of the mold is lower than the dew point of the surrounding air. In warmer or humid climates, it is recommended to raise the temperature of frozen water when using a water-cooling system to avoid condensation water remaining on the outside of the mold.

An external cooling source, such as a tower or an evaporative condenser, is required for a water-cooled refrigerator. The cooling tower pumps the warm water into the chiller.