Over 20 Years of Mold Design and Making

The founder established a mold company in 2002. With over 20 years of accumulated experience, we can provide stable-quality and cost-effective mold making services.

RJC has a manufacturing base in Shenzhen, China, covering an area of 10,000 square meters, with more than 40 engineers. Our factory is equipped with CNC machining centers and EDM machining centers for precise mold making.

Our mold costs are highly competitive for short-term and rapid prototyping applications.Our process is very fast and cost-effective, using the intended correct materials in the final production components. This allows our customers to bring their products to market faster and at a lower cost.

More importantly, it gives customers in rapidly changing markets more time and flexibility to make production decisions, tooling adjustments, and engineering changes based on market demand.

Types of Molds We are Offering

Discover the Range of Mold Types Tailored for Precision Manufacturing Needs

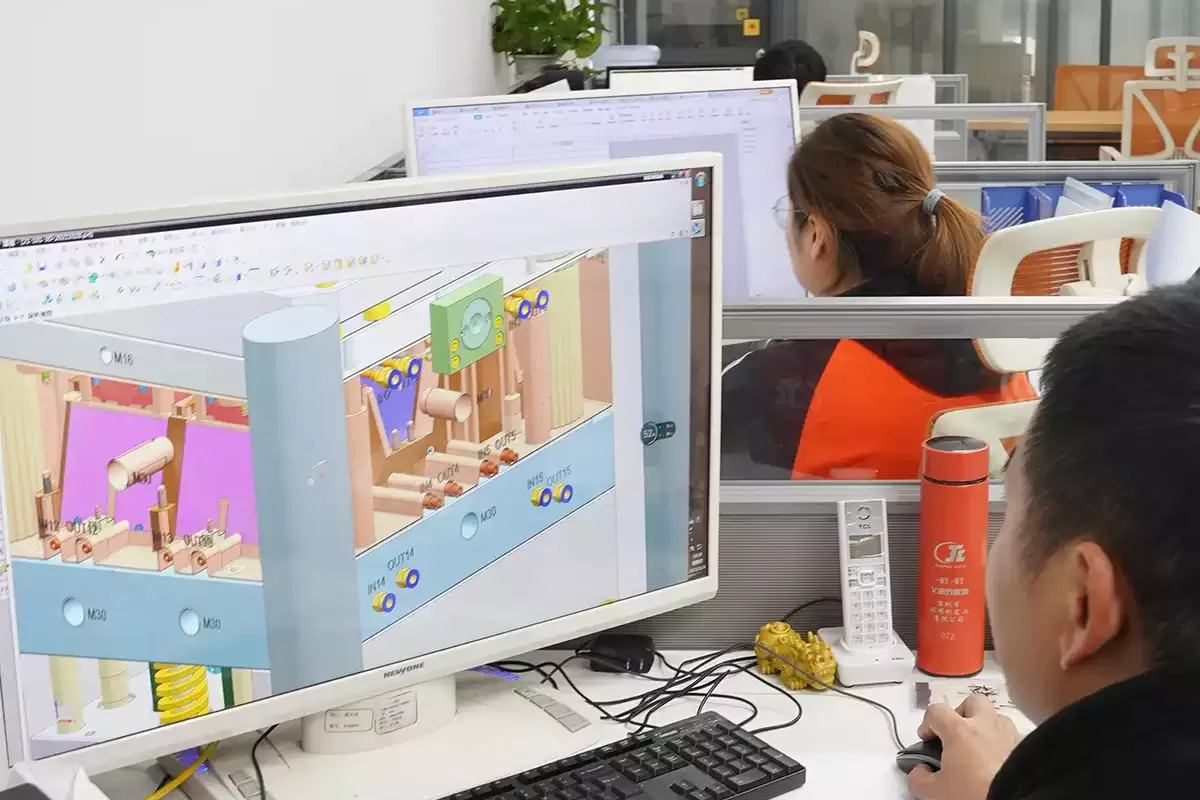

Mold Design Process

To satisfy the requirements of the customers, RJCmold designs and manufactures the molded parts under the considerable analysis and strict molding process.

Step 1: Analyze the product drawings

Step 2: Create the Design for Manufacturing (DFM) report

Step 3: Made the mold flow analysis

Step 4: Design tooling drawings

Step 5: Mold making

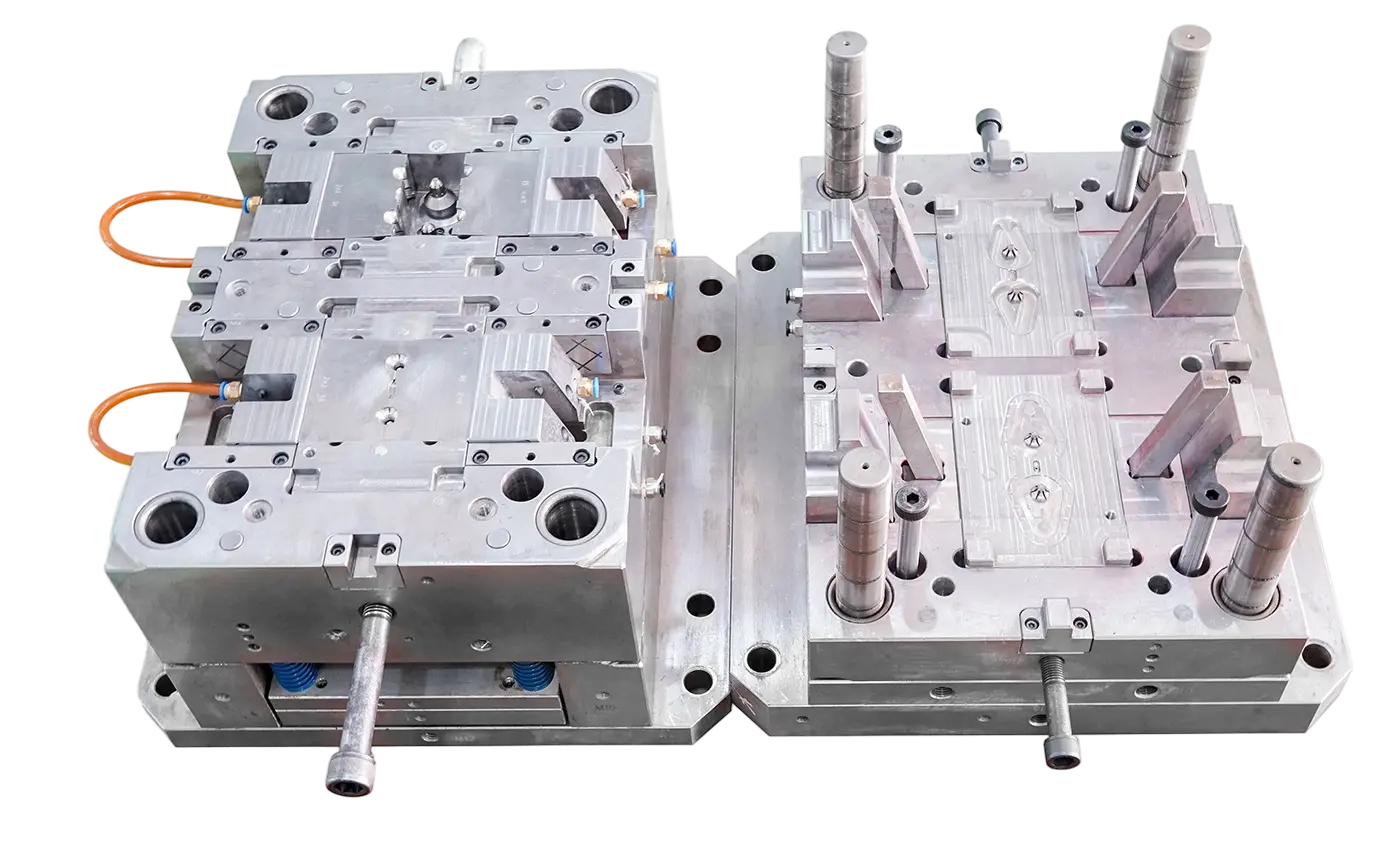

Full Service Molds Manufacturer

- Comprehensive mold management

- Full Service Mold Maintenance

Quick mold enhancements completed in house - Build fixtures and gages for consistent quality parts

- Mold capabilities include CNC 3D Machining, EDM, polishing and texturing.

- Hard and soft tooling

- Tool history documentation

- Various frames and configurable molds

- Correct issues with gating, venting and cooling

- Complete refurbishments

- Inspection fixtures are engineered and built in house

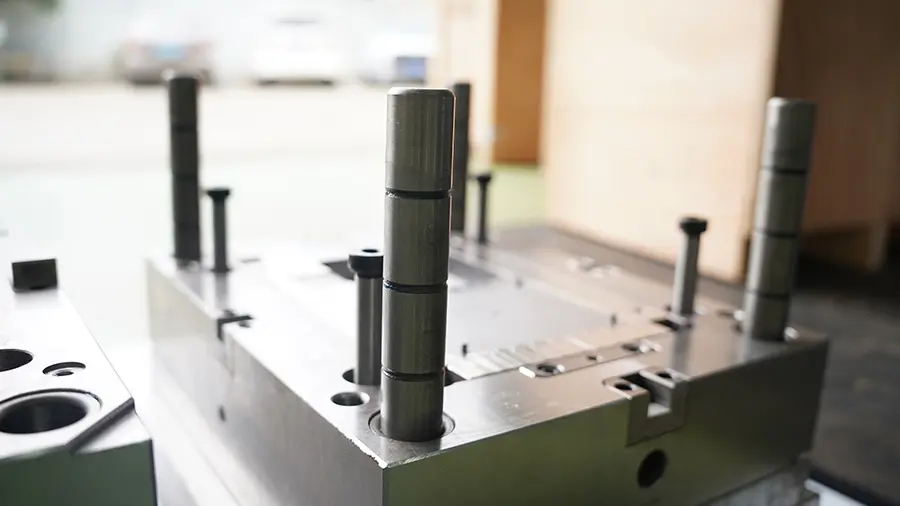

Precision mold manufacturing

RJC precisely mold making using 5-axis and EDM processes.Many dies are machined so precisely that they have a tolerance of less than one-thousandth of an inch.

Our 5-axis machine cuts across X, Y and Z axes along with rotating on the A and B axes. 5-axis CNC machining enables us to do the most complicated mold designs for our clients.

Plastic molds are commonly used with softer materials and for short production runs. Metal molds made out of steel, aluminum and other alloys have the durability to last for long product runs.To learn tips for designing for the injection molding process,

please download our Design for Manufacturability ebook below.

If you have questions regarding current or future projects, please contact RJC any time.

choose the correct material

At RJC, we make great tools for low-volume manufacturing. When making your mold tool we use pre-hardened tool steels such as P20 and NAK-80 and fully-hardened S136 tool steel.

The material used will depend on your specifications, the type of raw materials that RJC uses, and the number of parts you want to produce. Such as PP , PP+GF(20%/30%),ABS , PC/ABS , PC,PA66 ,POM,PA66+GF( 20%/30%/40%),PPA, PPS,TPE , TPU , TPV etc……

Our Advantages of Mold Making Services

Bring your project to life at advanced prototype molding. Whether you need a rapid mold prototype or a finished production run, RJCmold has the skills and experience to guarantee superior results.

We offer specialty tooling, custom casts, and full production runs for all manner of rubber, metal, and plastic products, and we strive to meet the needs of clients across industries. To learn more about whether our capabilities are right for you, contact our team, or request a quote to get started.

Expert manufacturability analysis.

Commonly known as DFM and moldflow analysis, our team of engineers perform expert manufacturability analysis on your injection molded parts at no charge. As a result, we have netted savings to our customers of up to 50% reduction in manufacturing costs!.

Design for Manufacturability (DFM), or more specifically analysis of a part design for its suitability to being injection molded, is performed to achieve the following:

- Minimize Tooling Costs

- Reduce Design Changes

- Expedite the Manufacturing Process

- Ensure Part Quality

RJC performs a manufacturability analysis on each injection molding project.

Upon receiving a quote request and an appropriate 3D design file, we will perform an initial analysis to ensure that the requested component is an appropriate candidate for injection molding.

Our objective is to produce the component closest to the original design intent. However, modifications are needed to accommodate the fundamental requirements of good injection molding practice in some instances.

In these cases, we discuss with clients suggested improvements to the design or measures we may need to take in the production process before initiating the mold production process to save our customers by minimizing tooling costs and design changes upfront and reducing overall project time.

RJC DFM and Mold Flow Analysis Example: Mold Flow Analysis

mold making without middlemen

Committed to providing excellent solutions for mold making, to enhance the safety, reliability, and environmental sustainability of production. From the parts design to prototypes and product assembly, RJCmold offers comprehensive technical support and services to our customers.

Our expertise extends beyond just mold making, as we also provide production of plastic products, surface treatment of products, part assembly, and custom packaging.

By offering these services under one roof, we are able to significantly shorten the lead time and reduce the development costs for our customers.

Related Posts

Explore insights, tips, and trends in mold design and manufacturing.