This is Bryan working in Shenzhen RJC Industrial CO., Limited and who have mold manufacture, design, injection molding experience more than 10+ years. Today, I’m talking what area can improve accuracy of medical molding components.

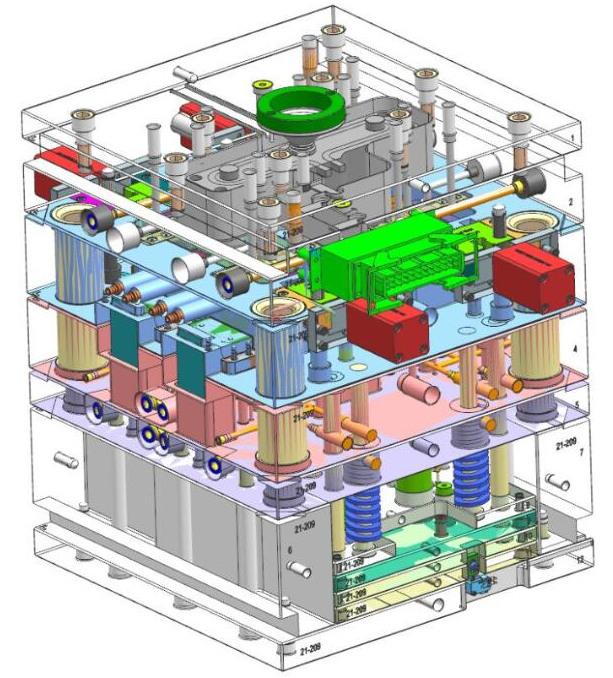

1,Mold design: RJC’s mold engineers are have more than 10+years experience, rich mold tech skills. What are they?

Knowledge of plastic materials: Good understanding of various types of plastics and their properties, as this will guarantee us in selecting the right plastic material for a specific application.

Familiarity with manufacturing processes: Good understanding of manufacturing processes, as this will guarantee us in designing the best structure for a mold and make it run smoothly.

Design skills: Strong design skills, including the ability to create complex 3D models, analyze designs for strength and durability, and develop efficient mold designs.

Knowledge of mold materials and construction: Good understand the advantages and disadvantages of each material for molds.

Problem-solving skills: Able to identify potential problems in a mold design and develop solutions to solve them fastest.

Communication skills: Good communication skills to work effectively with other members of the engineering team, as well as with production staff and marketing team/customers.

Project management skills: Able to manage our time effectively to meet project deadlines and able to manage multiple projects simultaneously.

Continuous learning: We commit to keeping up with the latest developments in mold design and plastic materials technology to stay competitive in the industry, and continue increasing our services and better support our clients.

Above skills of RJC engineer team to guarantee the mold run smoothly and could reduce the risks for all projects.

2,Mold processing: This is the main step for making high precise molds. But how RJC company to guarantee this process?

2.1, Equipments;

High speed CNC machines: RJC company brought 4 set new CNC machines NXV 600A from Taiwan in Apr,2022 . All the components of mold, such as cavity, core, inserts, mold base components are will do machining by CNC, which will guarantee the parts are precise.

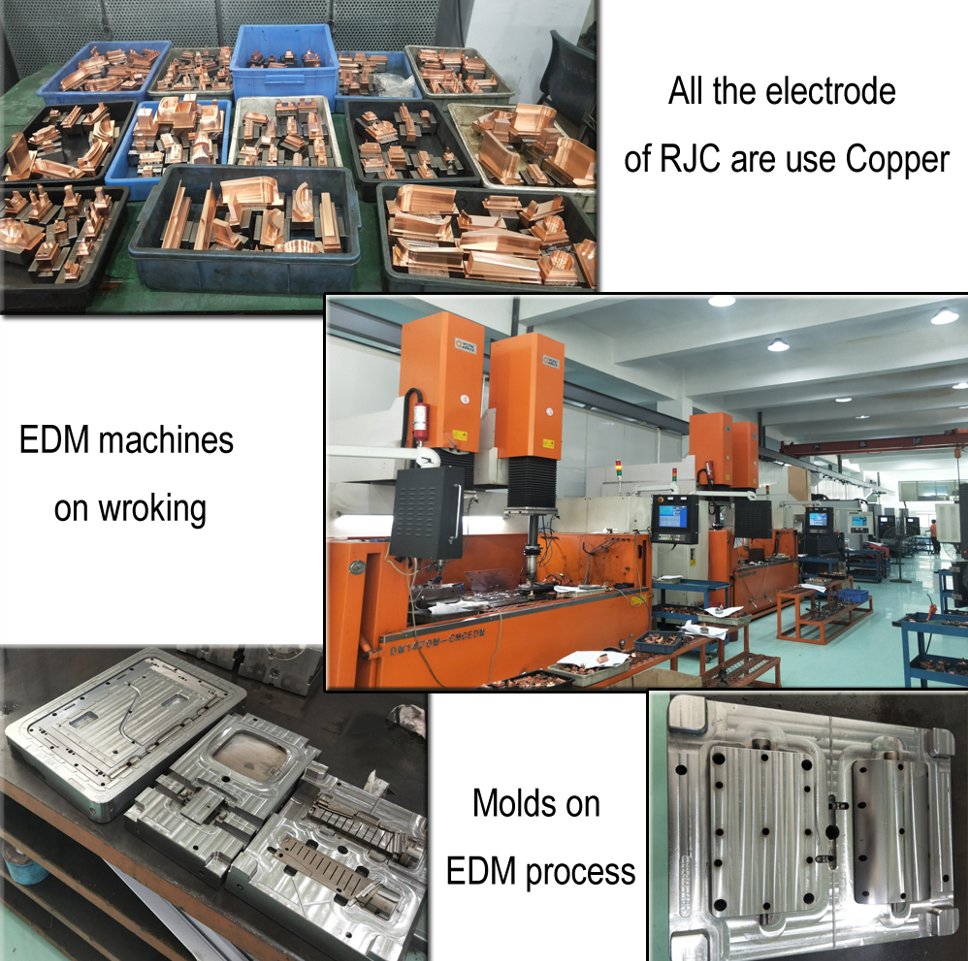

EDM Machines: Electrical Discharge Machining is a common process with high precise in mold manufacture, RJC company use two shots DM1470M-CNCEDM machines increase work efficiency and accuracy. On the other hand, RJC always use copper to make electrodes, and all the electrodes are measure by CMM, they can only be used if they passed.

WEDM: Wire Electrical Discharge Machining, RJC use low speed WEDM can improve the accuracy of the mold components, mostly are use for mold inserts, ejector pins holes, lifter holes and lifters.

Mold base purchasing: RJC purchase the mold base with good brand, it can guarantee the quality meet our demand of accuracy. And guarantee the accuracy of molds, this is also very important if we want to get high precise final plastic parts. Of course that will cost a little more, but at the end you will know it worth their value.

The experience of mold makers: Mold making is a specialized skill that requires a combination of technical expertise, precision, creativity, and attention to detail. RJC mold makers 60% are working in mold manufacturing more than 10 years, they have rich experience and able to handle high requirements, high precise and complex mold structures.

Good understand the properties of metal and plastic material and each process of mold processing. Able to troubleshoot and solve problems that arise during the mold-making process, also creative solutions to design and manufacturing challenges. A rich experience mold maker can reduce the risk some irreversible error, good mold fitting skills will affect the final quality of plastic products.

Measurements: RJC team will measure all the mold components by CMM, the main place will control under 0.01mm. And also will measure all the electrodes of EDM by CMM, it will control under 0.01mm. This way it’s very helpful to control the mold quality and more precise. This is also one of the main processes to improve accuracy for medical plastic components or other industry plastic parts.

3, Injection molding technology and equipments; RJC purchase twenty new injection machines in 2021, and injection molding engineers are more than 10years industry experience, they can handle different industries molding projects, Good understanding of various types of plastics and their properties, match colors, how to dry the raw material before molding, rich experience to control the mold temperature, injection pressure, cooling time, set up the robot to pick up the products automatic, solve different product issues like sink marks, warped, dimension control, etc

After the mold testing successful, RJC production team will record the molding data, and prepare the information of quality control process, like SOP, SIP,CP etc, these will used for future mass production.

All the processes above are RJC team how to improve accuracy for medical plastic injection molding parts or other industries molding parts. Welcome to contact us if you have any questions, or different opinions.

Thank you.