Injection molding cost

What is the cost of injection molding? At RJC, we want you to better understand the cost of injection molding. We break down the various cost factors associated with plastic injection molding in the following blog post.

The costs involved in making injection molded parts fall into two categories. The first is the one-time cost of injection mold, and the second is the cost of producing parts.

Cost of injection mold

- Part complexity

The most important factor in the mold cost of plastic forming parts is the complexity of the parts. Injection molded parts with many sharp corners, thin ribs, or bottom cuts are usually more expensive to mold.

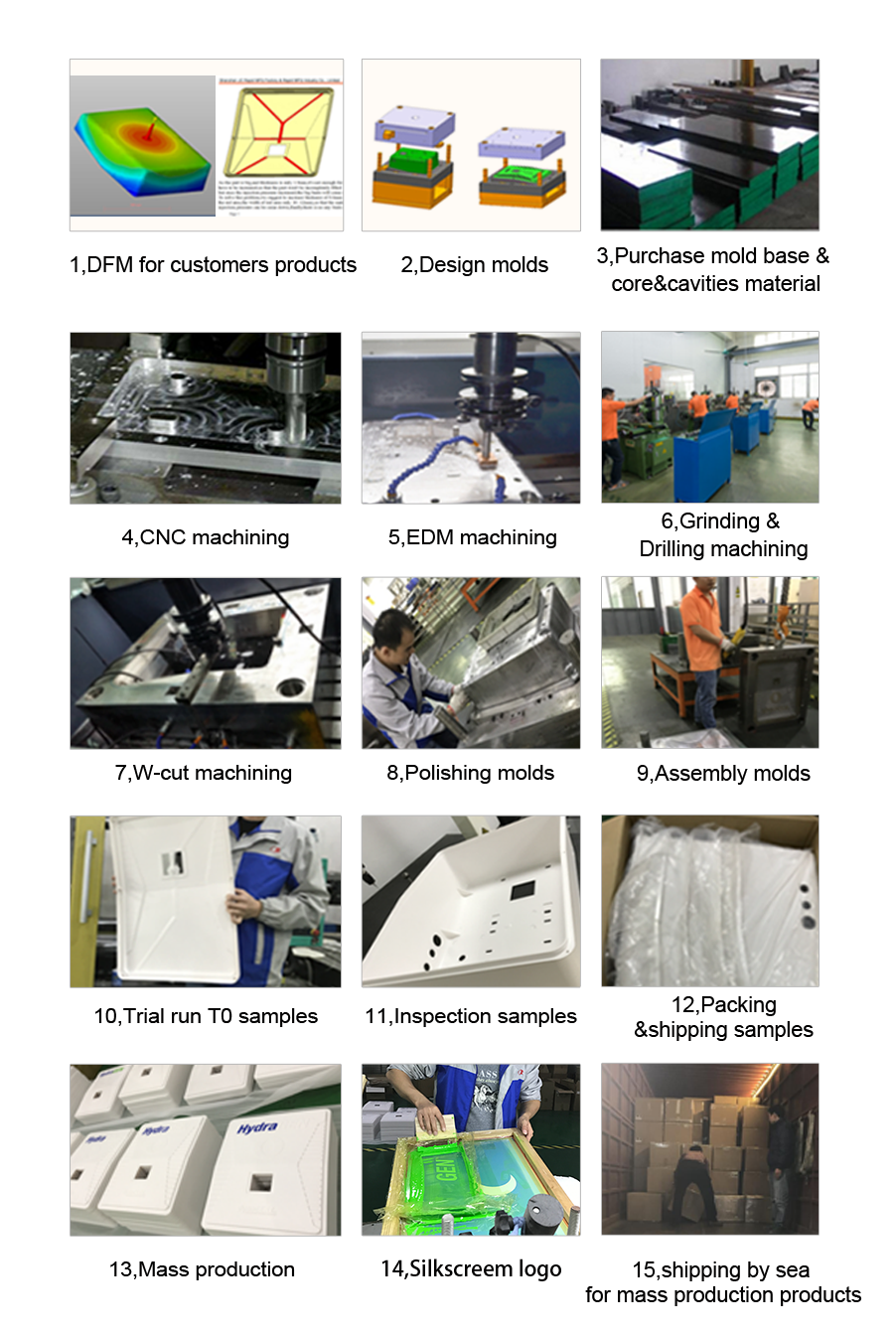

If the position of sharp corners prevents machining die features with round knives, they will require a secondary machining process called EDM machining. Similarly, riblet features that need to be machined in a mold deeper than 1/2 inch and thinner than 1/16 inch may also require secondary EDM machining.

The bottom cutting feature in the design of plastic parts always increases the cost of plastic injection mold. Reduce the cost of mold design time and machining time. They may also sometimes require the overall size of the die to be larger to accommodate the space required for the “side action” (moving parts) that forms the bottom cut feature.

- Mould manufacturing

There are many different injection mold construction methods for the endless variety of different part shapes, and many different reasons for their place in the injection molding industry. However, in the basic overall injection mold structure, we like to simplify them into two groups: “insert molds” and “free-standing molds.” Please visit our injection mold page to better understand each one.

Within each group, there are hundreds of different styles, sizes and complexities in the industry, but from a general cost perspective, plug-in molds will cost significantly less than free-standing molds.

What is the cost of injection molding?

As mentioned above, there are many different styles of side actions in die construction that are used to release plastic parts with bottom cuts during part ejecting. Many of our competitors use the lowest-cost side-action method, often referred to in our industry as “manual loading.” Manual loads are loose parts of the mold that eject from the mold with the parts, need to be manually removed from the parts, and then re-inserted into the mold by a human at each molding cycle.

Manual loads are a low-cost tool option for handling inverted part features in molds, but they can increase part costs and can lead to inconsistent part quality. At RJC, we prefer to use more “automatic” side actions in our molds because they enable a faster and more consistent injection molding process, resulting in better parts for our customers at a lower cost.

It is true that the manufacturing cost of an injection mold with automatic side action is higher than that of a hand-loaded mold, but for any production quantity greater than a few hundred pieces, the savings in part costs usually offset the increased manufacturing cost of the mold.

Number of cavities of parts

The number of cavities in the mold will directly affect the price of the mold. Parts requiring only a small number of parts per customer order will be constructed as 1-cavity molds, producing only 1 part per machine cycle, and parts requiring a large number of parts per customer order may be constructed as 2, 4 or 8-cavity molds producing multiple parts per machine cycle.

The cost of a multi-cavity mold is certainly higher than that of a single-cavity mold, but keep in mind that part pricing is inversely proportional to mold cost when considering mold cavities and total project costs.

- Component size

Perhaps the easiest to understand mold cost factor is the relationship between part size and mold cost, since the size of a plastic part is directly related to the mold size required to produce the part. As a result, larger molds require more building space, larger, more expensive CNC machinery and equipment to process them, etc.

- Cost of molded parts

In some cases, however, there may be some crossover between cost and scale. For example, a very complex design of a small injection mold can be more expensive than a very simple design of a large injection mold.

Material selection and part weight

The plastic material you choose for plastic parts is not only critical to the function of the part, but also plays a huge role in its manufacturing cost. The cost of plastic raw materials ranges from $1 to $25 per pound. Therefore, in the design of plastic parts, attention should be paid to reduce the weight of parts as much as possible.

Choosing the right type of plastic can also help speed up the cycle time or productivity of the part, thereby reducing the overall cost. For small parts, material cost has little impact on unit price, but productivity has a great impact. For larger and heavier parts, material cost has a great impact on unit price and productivity.

$material part cost = $plastic material price x part weight LBS

Cycle time and mold cavity

“Cycle time” is the term used in our industry for injection molding and CNC machining. In simple terms, it is the time it takes a machine to complete a production cycle. The entire injection molding cycle time consists of the following steps:

- Closing time

- Injection filling time

- Injection kit/hold time

- Cooling time

- Open mould time

- Part ejecting or pulling time

- Recirculation time (only applicable when parts must be run by machine operator in semi-automatic mode)

So how does cycle time relate to part cost? Let’s discuss the major sources of non-material related costs for injection molding.

Non-material related costs

Let’s start with machinery and equipment. Today’s high-tech servo driven injection molding machines are very expensive. The tonnage grade of the machine and its surrounding supporting equipment will determine the overall capital investment required to run production. Small tonnage machine sizes are used to run small molds and small parts, while large tonnage machines need to run large molds and large parts.

Even small injection molding machines and their supporting equipment will cost close to $100,000, while very large machines will cost millions of dollars. It also suggests that the effective life cycle of a machine is limited, as it wears out over time and loses its technological edge to new technologies over time, as everything does now. Knowing that cost is the capital (dollar) investment of the machine divided by its effective life cycle (time), it is easy to understand that this translates into the hourly operating cost of the equipment.

In addition to the capital equipment costs discussed above, there is a combination of fixed and variable costs, such as manufacturing space rental, electricity usage, etc. These costs can also easily be built into the hourly operating costs through simple math.

The sum of all non-material related hourly costs combined with profit margins becomes what is known in our industry as the “machine rate”.

Finally, here is how simple non-material related costs for injection molded parts are determined by cycle time:

Units produced per hour = (3600 seconds/cycle time seconds) x number of cavities

$Non-material parts cost = $machine rate per hour/units produced per hour

Because machine speeds in the injection molding industry are very competitive, cycle time and the number of cavities in the mold are two important determinants of the total cost of plastic molded parts.

Packaging and accessories

The other two items that really have a significant pricing impact on molded parts are packaging and extra handling. The following common requirements may increase the cost of injection molded parts:

- Layer is installed

- Cells in the packaging

- Polythene bag

- Retail packaging

- electroplating

- painting

- Pad printing

- Secondary processing

Injection molding cost

All of these factors add up to the cost of injection molding involved in your project. Call or email now to get in touch with one of our sales engineers! We will provide you with the most suitable product plan and the most suitable price

To discuss your next order or to discuss our custom plastic molding services, please send email [email protected] to talk to one of our team members.