Mold design is an important part of any product manufacturing process. The design team will need to consult with the tooling and cutting tool suppliers and will need to consider manufacturing design principles to ensure successful production. Mass-produced artifacts require tools such as molds to be designed to precise specifications before the process can begin. If there are no well-designed die-cutting tools, will produce poor quality goods, prone to failure, resulting in the whole batch of products being wasted. Then, the manufacturer had to “start from scratch” and restart production, wasting a lot of manpower, materials, and time. To avoid costly mistakes, the manufacturer should consult closely with the mold designer. Mold designers can assist product manufacturers before and during production.

What is a die tool

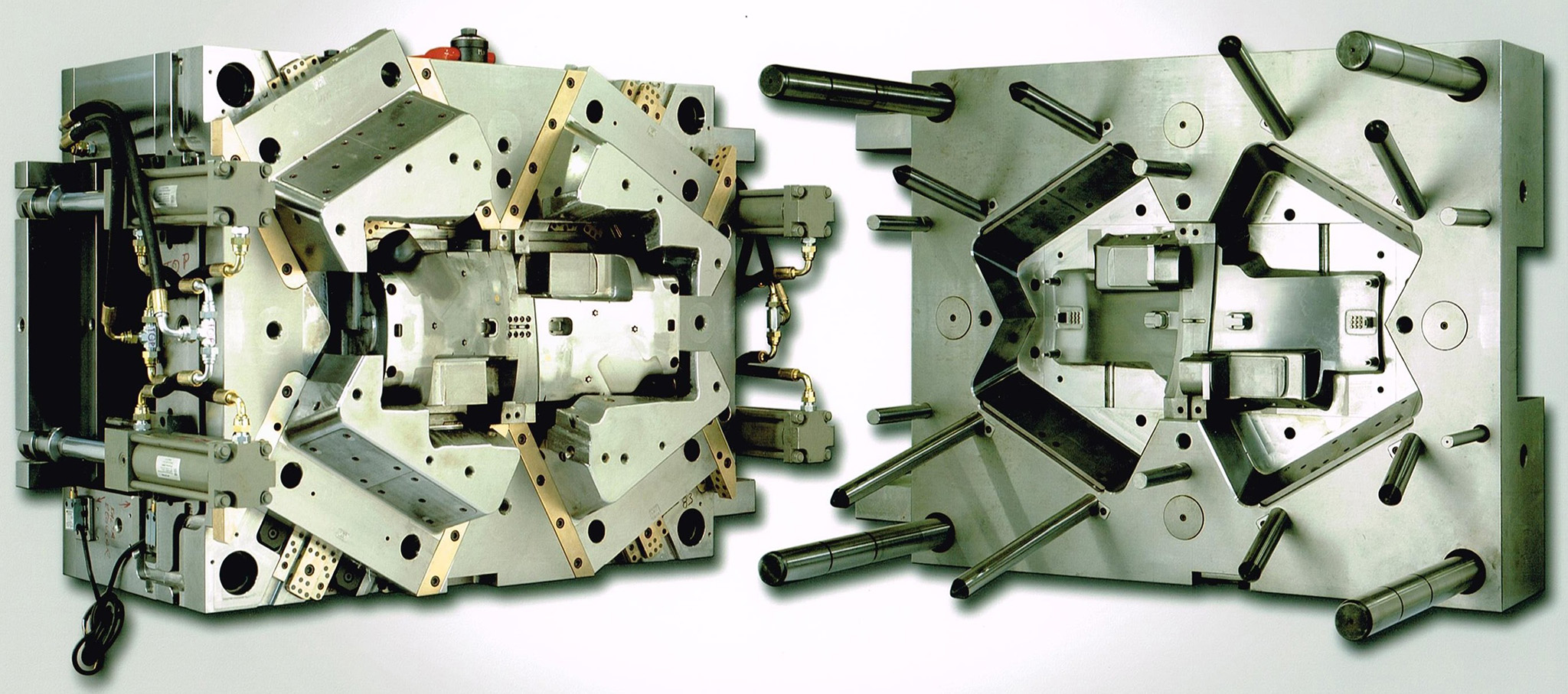

A die is a special tool used to form or cut materials for manufacturing. Mass-produced synthetic products require tools that resemble forming molds, and these tools must be designed according to process specifications before the production process can begin. Externally designed die-cut tools secondary objects will be constructed that have had lead to the failure, following in whole product batches remain term. Mold design at various stages in the product manufacturing process plays a vital role. Once the production process is complete without any errors, the design for the manufacturer will provide assurance for the quality and productivity of the material.

Tool design process:

The tool designer should follow the process of producing the product.

1. Problem statement and analysis

The tool designer can evaluate the status of the manufactured product and analyze problems in the manufacturing process.

2. Analyze requirements

Tool designers should design tools according to the manufacturer’s expected product requirements. The designer can analyze the structure of the product, the feel, and so on.

3. Development of initial ideas and design alternatives

The tool should be designed and that should develop the initial ideas for the manufactured products. The tool designer should also design an alternative tool for the same product. The tool may be 2 or not But for the safe side, designers should prepare a similar kind of tool for any misleads.

4. Finalize the design concept

The tool designer should complete the tool design process according to the needs of the product. If the designer is confident that the tool meets the required requirements, then the tool design process is complete.

The quality, performance, speed, and precision of the finished parts and the repeatability of mass production all depend on the precision and characteristics of the tool.

Therefore, for the best parts, tools need to be designed and engineered to the highest quality.

About us

RJC is a manufacturer from China, was founded in 2002. Our slogan is “Rapid, Joyful and Creative”. Our services include:

1) In-house production molds (Plastic & Die-casting)

2) Injection molding

3) Exported molds (deliver molds to overseas for molding locally)

4) Rapid prototype ( 3D printing, machining & Vacuum Casting)

5) Precision CNC machining ( Milling & Turning)

6) Silicone components (LSR & Compression)

7) Sheet Metal

8) Post-processing ( painting, plating, printing, anodizing, chroming, etc…)